Understading PlastiC Injection Molding's Lifespan

Plastic injection molding is one of the most popular and efficient methods for manufacturing plastic parts and components. It’s widely used in industries ranging from automotive and electronics to consumer goods and packaging. This versatile and high-precision manufacturing technique offers rapid production speeds, complex geometries, and cost-effectiveness, making it the preferred choice for mass-producing plastic products. However, while plastic injection molding is undoubtedly a powerful tool in manufacturing, understanding the lifespan of the molded components and the injection molds themselves is critical for ensuring that the products meet quality standards and remain cost-effective over time.

- What is Plastic Injection Molding?

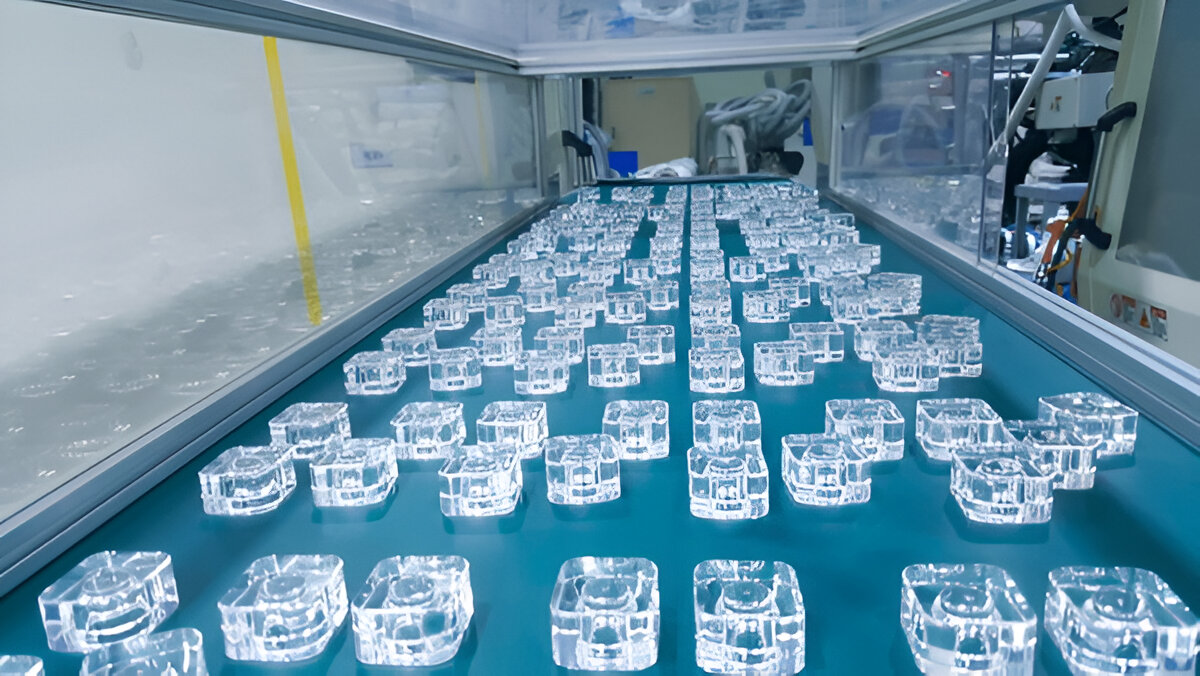

Plastic injection molding is a widely used manufacturing process that produces plastic parts and components by injecting molten plastic material into a precisely shaped mold. It is a versatile and efficient process that allows for high-volume production of complex and intricate designs, making it an essential method for producing everyday products used in industries such as automotive, electronics, medical devices, packaging, consumer goods, and more.

In the injection molding process, raw plastic materials, often in the form of pellets or granules, are first heated until they become molten. This molten plastic is then injected into a mold under high pressure, where it cools and solidifies into the desired shape. Once the plastic has cooled and hardened, the mold is opened, and the finished part is ejected.

Key Steps in the Plastic Injection Molding Process

The injection molding process consists of several critical steps, each contributing to the production of high-quality, precise plastic parts. Here’s a breakdown of the typical process:

- Material Preparation

The process begins with the preparation of the plastic material. The raw plastic comes in the form of pellets or granules, which are then fed into a hopper. These pellets are typically made from thermoplastic polymers, such as polyethylene (PE), polypropylene (PP), polystyrene (PS), or more specialized engineering plastics like polycarbonate (PC) or nylon (PA). Some plastics may also include colorants, additives, and reinforcements (like fiberglass) to enhance the material’s properties.

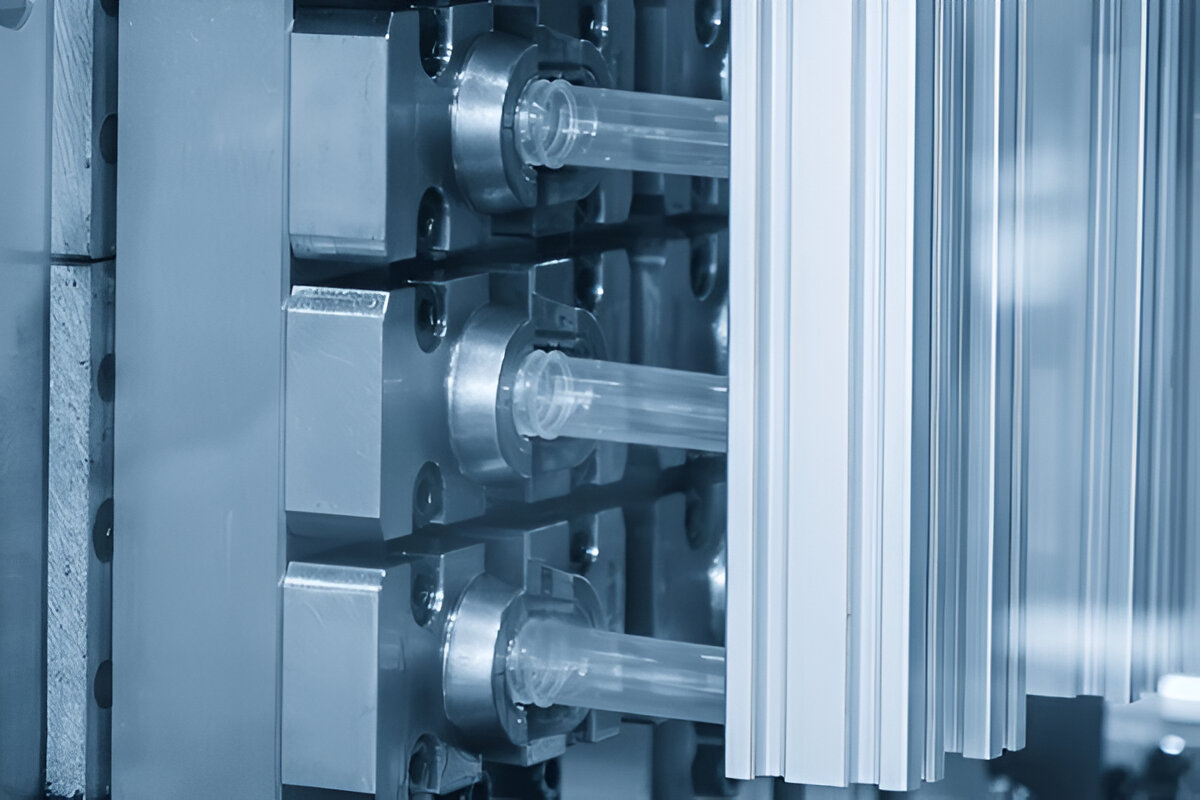

- Melting the Plastic

Once the plastic material is fed into the hopper, it is carried into a heated barrel, where it is melted by a combination of heat and mechanical shear force. The barrel is equipped with a rotating screw that helps to melt and mix the plastic as it moves along the barrel. The temperature is carefully controlled to ensure that the plastic reaches the right viscosity for injection. The molten plastic is now ready to be injected into the mold.

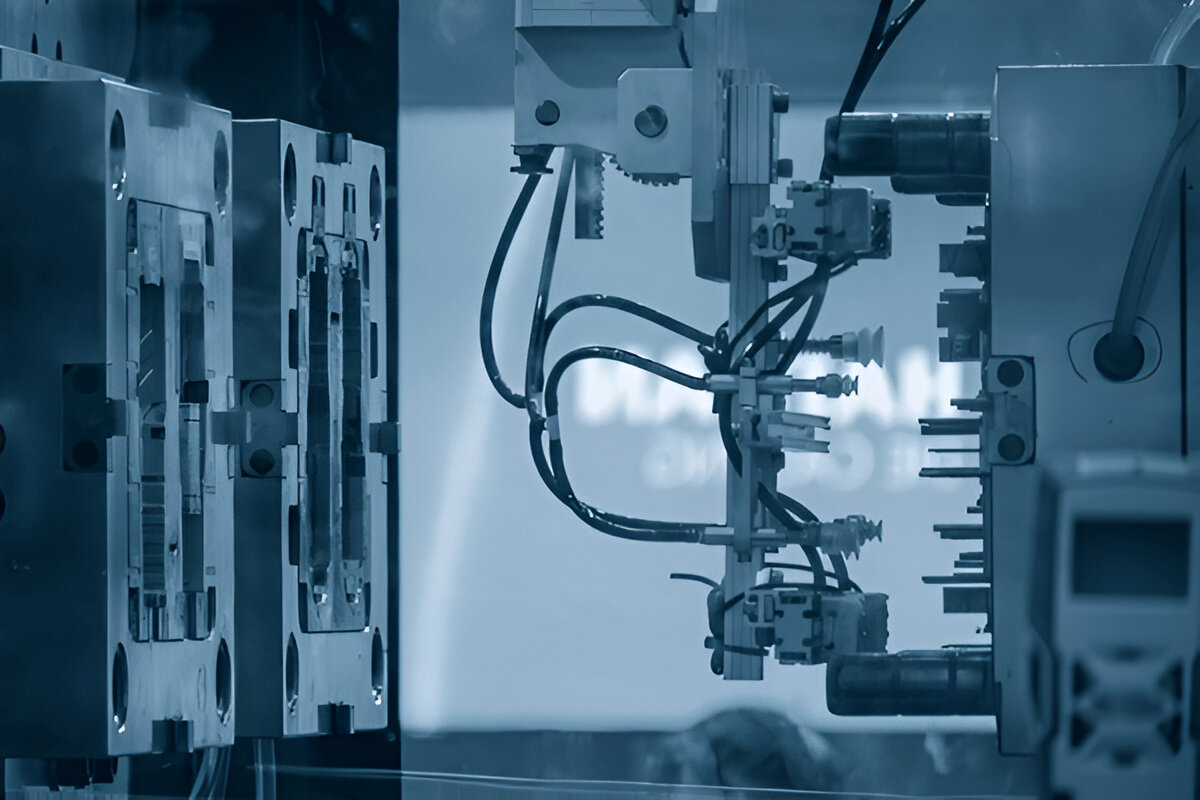

- Injection Into the Mold

The molten plastic is injected into a metal mold cavity through a nozzle at high pressure. The mold is typically made from steel or aluminum and is designed to form the shape of the desired part. The mold consists of two halves: the core (which forms the inner shape of the part) and the cavity (which forms the outer shape). The pressure ensures that the mold is completely filled, even in intricate or detailed areas.

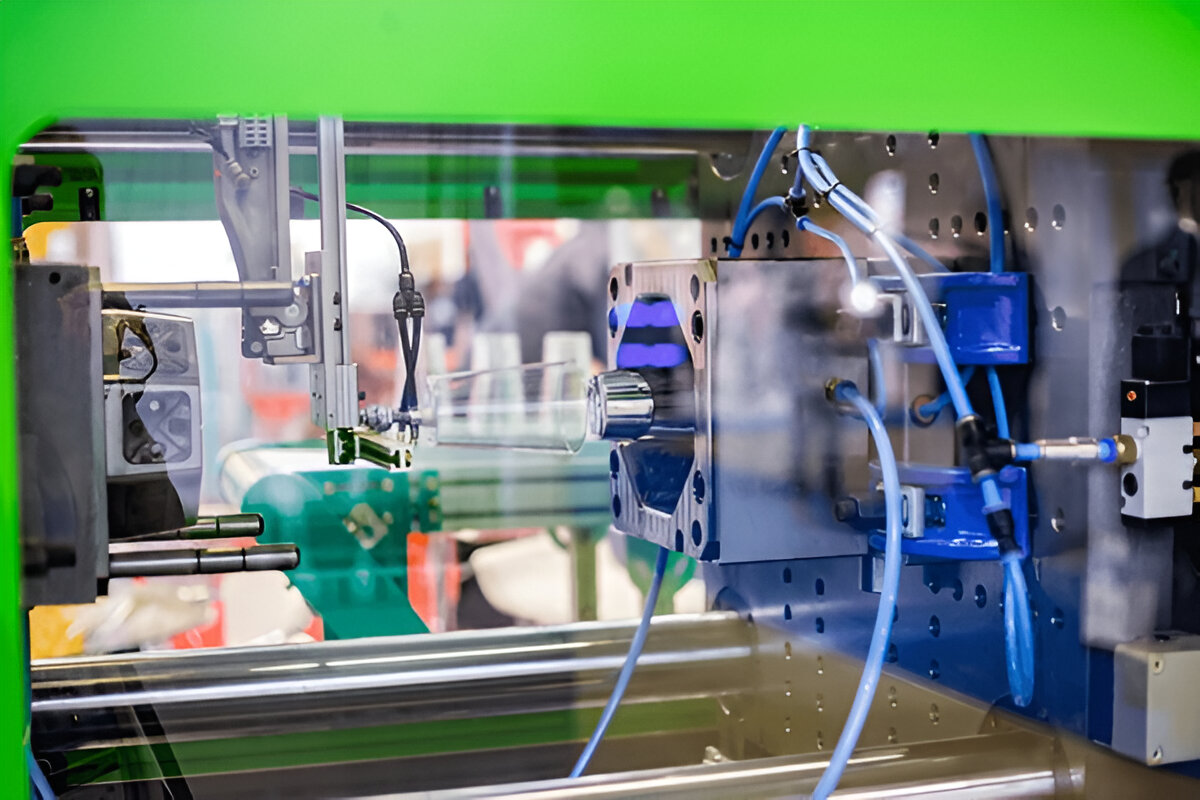

- Cooling and Solidifying

After the mold is filled with molten plastic, the next step is cooling. The mold is kept at a controlled temperature, and the molten plastic begins to cool and solidify. Cooling channels within the mold help regulate the temperature and speed up the cooling process. The cooling time depends on factors such as the thickness of the part and the type of plastic used.

- Ejection

Once the plastic has cooled and solidified into the desired shape, the mold halves are separated, and the finished part is ejected. The part is typically removed using ejector pins or other mechanical devices that push the part out of the mold. After ejection, the part may require some additional finishing, such as trimming excess material or adding inserts.

- The Lifespan of Injection Molding Products

The lifespan of plastic injection molded products refers to how long the finished plastic part remains functional and structurally sound. In many applications, the lifespan of the product is crucial, particularly when the component is exposed to stress, chemicals, or extreme temperatures.

Several factors influence the lifespan of injection molded products, including:

a. Material Selection

The plastic material used in injection molding plays a significant role in determining the lifespan of the product. Different plastic materials have varying degrees of durability, chemical resistance, temperature tolerance, and wear resistance. For instance, parts made from thermoplastics like polyethylene (PE) or polypropylene (PP) may have a different lifespan compared to those made from engineering plastics like polycarbonate (PC) or nylon (PA), which have superior strength and heat resistance.

When choosing the right material, manufacturers need to consider the intended application of the part. For example, plastic parts used in outdoor products need to be resistant to UV radiation and weathering. On the other hand, components in automotive or medical devices may require materials that can withstand higher temperatures and mechanical stress.

b. Environmental Conditions

Environmental conditions, such as temperature, humidity, and exposure to chemicals or UV light, can significantly impact the lifespan of plastic injection molded products. For example, exposure to extreme temperatures can cause plastic parts to warp or degrade over time. UV light can break down certain plastics, causing them to become brittle and crack, especially if the material is not UV-resistant.

In industrial applications, parts exposed to harsh chemicals, oils, or solvents can experience degradation. Choosing the right material for the environment is key to ensuring a long lifespan for plastic molded parts. Special coatings or additives can be applied to enhance the resistance of the plastic to these environmental factors.

c. Mechanical Stress and Wear

Plastic components that are subject to mechanical stress, friction, or wear will naturally experience a shorter lifespan. For example, plastic parts used in moving machinery, automotive components, or consumer goods that undergo repetitive actions (such as buttons or hinges) are more prone to wear and fatigue.

Some plastics are more resilient to wear and tear, while others may lose their integrity after repeated use. For example, high-performance materials like acetal (POM) and polyamide (PA) are designed to withstand mechanical stress, making them ideal for applications such as gears, bearings, and structural components.

d. Design Considerations

The design of the injection molded part also affects its lifespan. Thin sections of plastic may be more prone to cracking or breaking under stress, while parts with sharp corners or edges may experience stress concentrations that weaken the material over time. Proper mold design, including the use of fillets (rounded corners) and avoiding thin walls, can help improve the longevity of the molded product.

Furthermore, the design of the product should take into account factors like load distribution, temperature cycling, and any potential areas of weakness in the part. The thickness of the walls, the placement of injection points, and the design of the cooling channels all play a role in determining how long the part will last under various conditions.

- The Lifespan of Injection Molds

The lifespan of the injection mold itself is another important factor to consider in the context of plastic injection molding. Molds are a significant investment in the manufacturing process, and understanding how long they will last is critical for production planning and cost estimation.

a. Material of the Mold

Molds are typically made from high-strength tool steels, which can withstand the pressure and temperature variations during the injection process. However, the material of the mold affects how long it will last. High-quality steel molds, such as those made from H13 or P20 steel, tend to have longer lifespans and can withstand more cycles before wear occurs.

For high-volume production runs, the mold material should be chosen based on the number of parts needed to be produced. A mold made from a durable steel may last hundreds of thousands to millions of cycles, whereas molds made from less durable materials may need to be replaced sooner.

b. Mold Maintenance

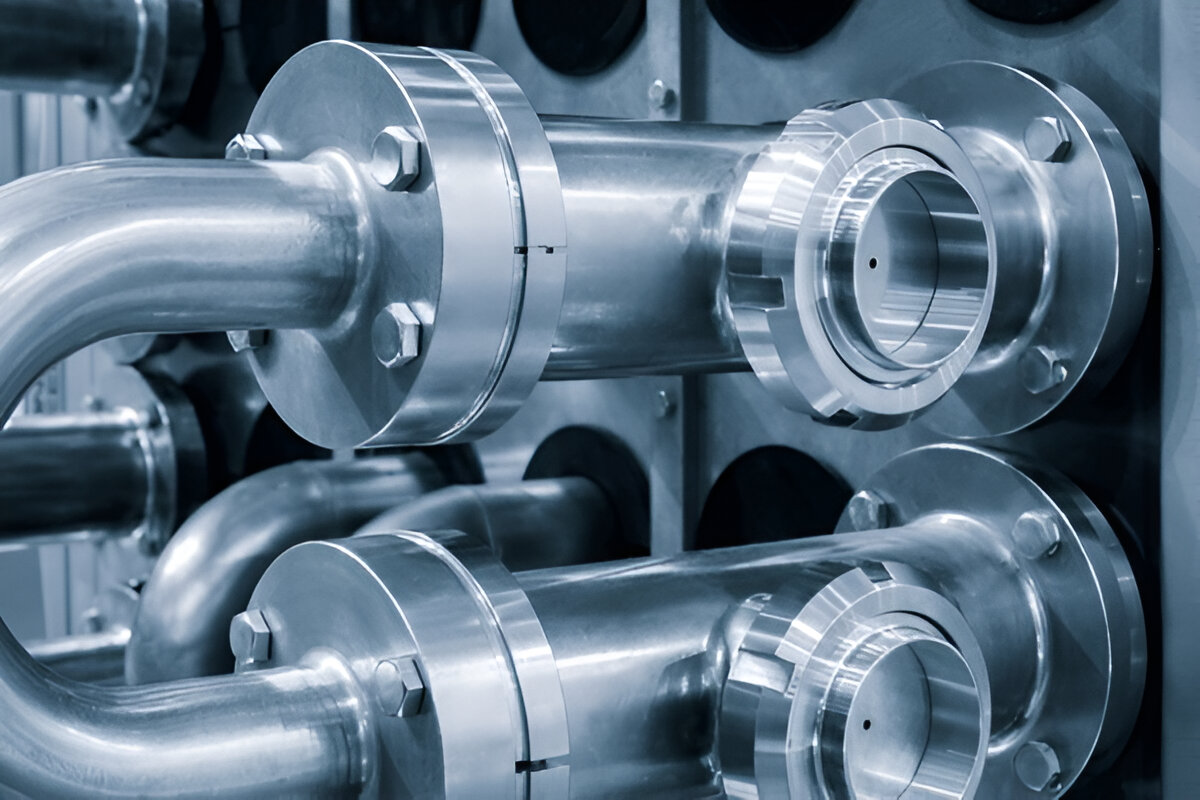

Mold maintenance is critical in extending its lifespan. Regular cleaning, lubrication, and inspection can help identify and address any wear and tear early on. For example, the injection molding process generates heat, which can cause the mold to wear down over time. Inadequate cooling or the accumulation of debris in the mold can also affect the lifespan and quality of the product. Regular mold maintenance will ensure that it remains in good working condition for longer and reduces downtime caused by repairs.

c. Mold Design and Construction

The design and construction of the mold also impact its lifespan. High-quality molds are designed to withstand the stresses of repeated use. Proper venting, cooling channels, and the positioning of the injection points help distribute pressure evenly across the mold, reducing the likelihood of damage or failure. On the other hand, poor mold design can lead to hot spots, warping, and other issues that reduce the mold's lifespan.

The construction of the mold should also account for the type of material being molded. Some materials, such as highly abrasive plastics, can cause more wear on the mold, leading to a shorter lifespan. Therefore, selecting the appropriate material for the mold is crucial in ensuring its durability.

d. Cycle Time and Maintenance Intervals

Cycle time, which refers to the time it takes to complete one injection cycle, can impact the lifespan of the mold. Longer cycle times put more stress on the mold, leading to a higher likelihood of wear. Additionally, the frequency of mold maintenance intervals directly correlates with how long the mold will last. Regular maintenance schedules can help identify issues before they cause major damage, ensuring the mold continues to produce high-quality parts.

4. Extending the Lifespan of Plastic Injection Molding

While plastic injection molding is an efficient and reliable manufacturing method, there are several strategies that can help extend the lifespan of both the molded products and the molds themselves:

a. Material Selection and Additives

Choosing the right material for the specific application is essential for ensuring the longevity of molded products. Materials can be engineered to withstand specific stresses, temperatures, and environments. For example, adding UV stabilizers, antioxidants, or flame retardants can enhance the durability of the molded plastic.

b. Mold Maintenance and Care

Regular maintenance of the molds, including cleaning, lubricating, and inspecting for wear, can significantly extend their lifespan. Routine checks for cracks, warping, or other issues will help prevent production delays and costly repairs.

c. Improving Design Efficiency

Proper mold design is vital in improving product lifespan. Optimizing the wall thickness, reinforcing weak areas, and ensuring proper cooling channels can all contribute to increasing the overall durability of both the product and the mold.

d. Utilizing High-Performance Materials for Molds

For high-volume production, investing in high-performance mold materials such as hardened tool steels or carbide inserts can dramatically extend the life of the mold. These materials are more resistant to wear and tear, which is critical when manufacturing large numbers of parts.

e. Monitoring and Testing

Implementing monitoring systems to track mold performance and product quality can provide real-time data, which can help identify issues before they lead to failures. Testing the products for durability and stress resistance throughout the production process can also help improve the design and ensure longer-lasting products.

- Conclusion

Plastic injection molding is a versatile and cost-effective method for manufacturing high-quality, precision plastic parts. The lifespan of both the molded products and the molds themselves plays a crucial role in determining the overall cost-effectiveness and efficiency of the manufacturing process. By understanding the factors that influence the lifespan of plastic injection molding, manufacturers can take proactive steps to improve material selection, design, and maintenance practices.

Incorporating these best practices will not only increase the longevity of the molded parts and molds but also reduce downtime, lower production costs, and enhance product quality. By understanding and optimizing the lifespan of injection molded products, manufacturers can ensure the reliability and durability of their components while maintaining a competitive edge in the market.