What industries commonly use CNC machining?

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computer-controlled machines to precisely cut, shape, and drill materials like metal, plastic, wood, and composites. This technology has revolutionized various industries, offering high precision, repeatability, and efficiency in production processes. The versatility of CNC machining makes it suitable for a wide range of applications, from creating intricate components for aerospace to mass-producing consumer goods.

In this blog, we will explore the various industries that commonly use CNC machining and how this technology is applied to meet their specific needs. We will also discuss the benefits of CNC machining for these industries, including the ability to create complex parts, reduce labor costs, and enhance overall production efficiency.

- Aerospace Industry

The aerospace industry is one of the largest and most demanding sectors when it comes to precision machining. Parts and components in the aerospace sector require exceptional accuracy and the ability to perform under extreme conditions. CNC machining plays a critical role in manufacturing various components such as engine parts, structural elements, and landing gear components.

Applications in Aerospace:

- Engine Components: CNC machining is used to create high-performance engine parts such as turbine blades, compressor blades, and other components made from advanced materials like titanium, nickel alloys, and other high-temperature resistant materials.

- Structural Components: CNC machines are used to manufacture large, complex parts like wing spars, fuselage sections, and wing ribs. The precision and repeatability of CNC machining ensure these parts meet the stringent tolerances required for safety and performance.

- Aircraft Interiors: CNC machining is also used to create components for the interior of aircraft, including seat frames, cabin walls, and overhead bins. The process is used to produce lightweight, durable, and functional parts with minimal waste.

Benefits to Aerospace:

- Precision and Quality: CNC machining ensures the high accuracy and tight tolerances needed in aerospace manufacturing, contributing to the safety and performance of the aircraft.

- Material Flexibility: CNC machines can handle a wide variety of materials, including hard metals and composites, which are commonly used in aerospace applications.

- Time Efficiency: With the ability to work with multiple materials and create complex geometries, CNC machining reduces production times and ensures faster turnaround times for prototype and mass production runs.

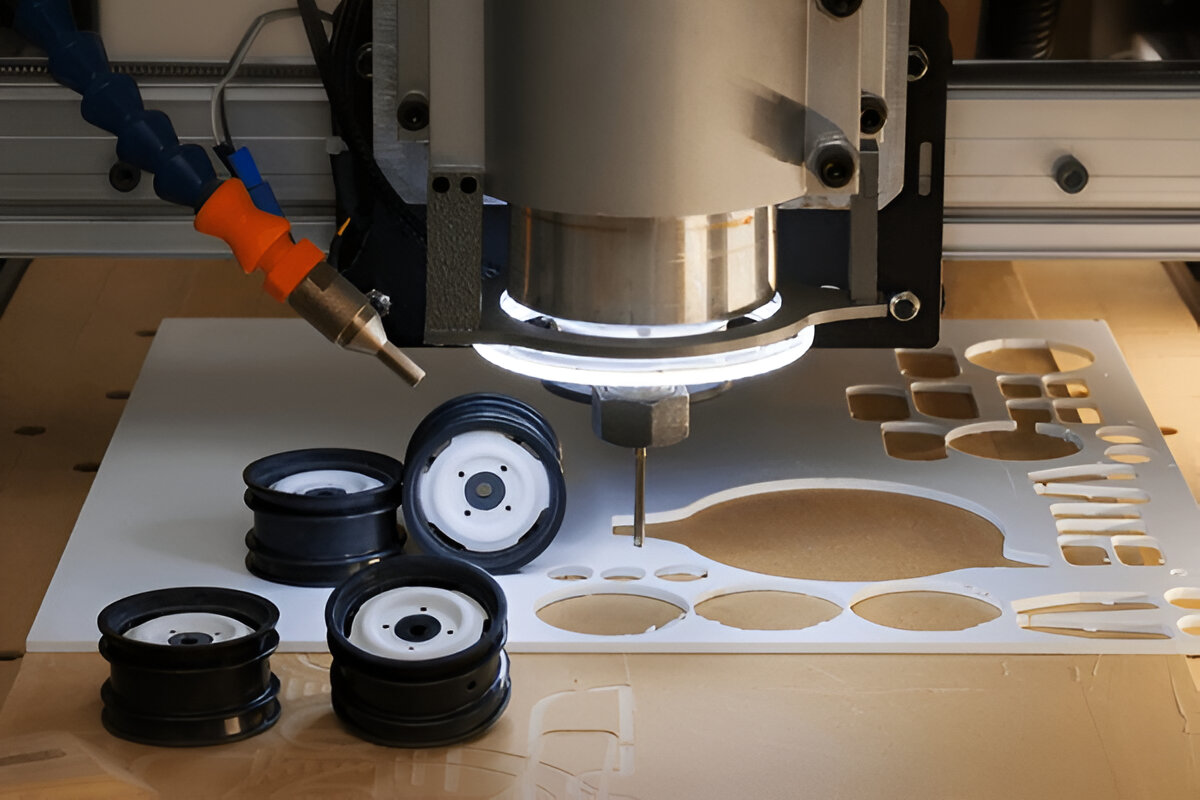

- Automotive Industry

The automotive industry relies heavily on CNC machining to produce parts that are both high in quality and cost-effective. CNC machining is used to manufacture everything from small, intricate components to large, heavy-duty parts for cars, trucks, and motorcycles. Whether it's for mass production or custom car parts, CNC machining helps meet the industry's rigorous standards.

Applications in Automotive:

- Engine Parts: CNC machining is used to manufacture high-precision engine parts such as pistons, cylinders, valves, and crankshafts. These components require accuracy and consistency to ensure optimal performance and reliability.

- Transmission Components: CNC machining plays a significant role in the production of transmission components, including gears, shafts, and housings. These parts must be machined to exact specifications to handle the stresses of vehicle operation.

- Chassis and Suspension Components: CNC machining is used to create chassis parts, suspension brackets, and other structural components that are designed for durability and high performance.

- Custom and Aftermarket Parts: CNC machining is also used to create custom parts for automotive enthusiasts, such as custom wheels, engine blocks, and performance parts.

Benefits to Automotive:

- High Production Volume: CNC machining offers high-volume production capabilities, making it ideal for manufacturing parts in large quantities at competitive costs.

- Customizability: CNC machines can quickly switch between designs, allowing manufacturers to produce custom components or prototypes for specific vehicle models or aftermarket parts.

- Efficiency: CNC machining reduces labor costs and the risk of human error, allowing for faster production times without sacrificing quality.

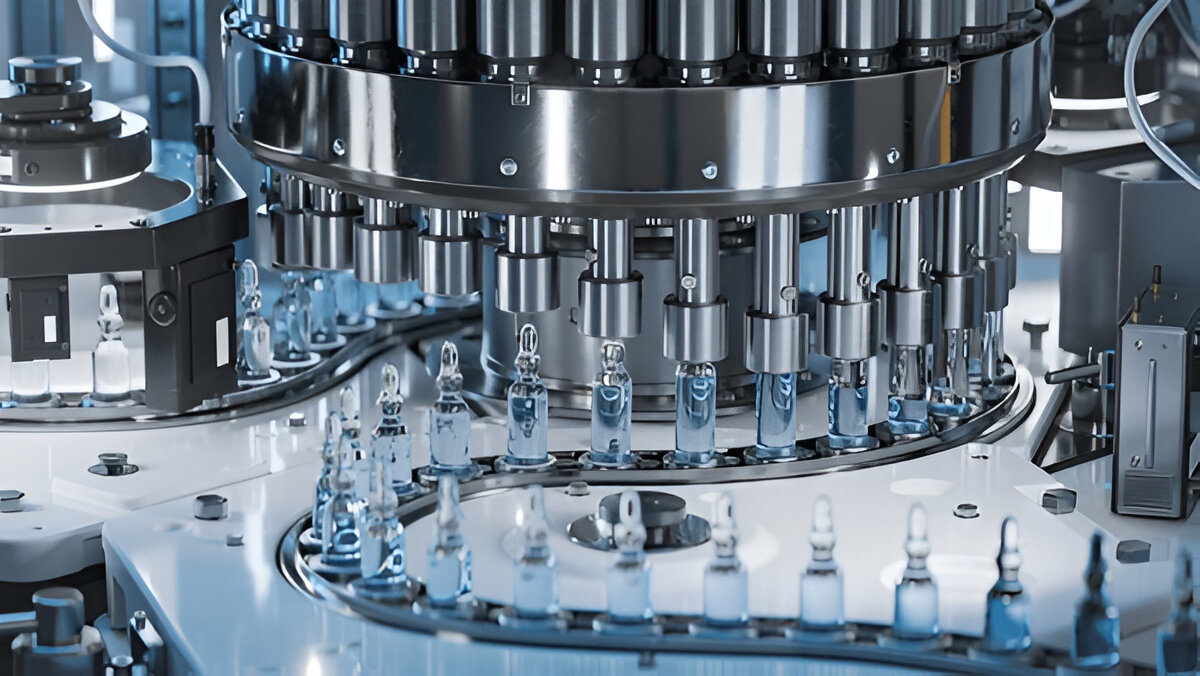

- Medical Industry

The medical industry requires components that are not only precise but also safe for patient use. CNC machining plays a vital role in the production of medical devices, implants, and instruments, providing the level of precision and consistency necessary for the highest standards in healthcare.

Applications in Medical:

- Surgical Instruments: CNC machining is widely used to manufacture high-precision surgical instruments such as forceps, scalpels, tweezers, and scissors. The ability to create sharp, durable, and accurate edges is critical in surgical applications.

- Orthopedic Implants: CNC machining is used to create custom orthopedic implants like knee and hip replacements. These implants must be manufactured to precise dimensions and designed to fit the patient’s unique anatomy.

- Dental Devices: CNC machines are used to create dental prosthetics such as crowns, bridges, and dentures. The precision offered by CNC ensures that these devices fit perfectly and function effectively.

- Diagnostic Equipment: CNC machining is used in the production of diagnostic equipment such as X-ray machines, CT scanners, and ultrasound devices, ensuring that these high-tech instruments operate efficiently and safely.

Benefits to Medical:

- High Precision: The medical industry demands ultra-high precision, and CNC machining ensures that components are made to exact specifications, which is crucial for patient safety.

- Material Versatility: CNC machines can work with a variety of biocompatible materials, such as titanium, stainless steel, and plastics, which are commonly used in medical devices and implants.

- Customization: CNC machining allows for the creation of custom parts and devices, such as patient-specific implants, which are increasingly in demand in modern medical practice.

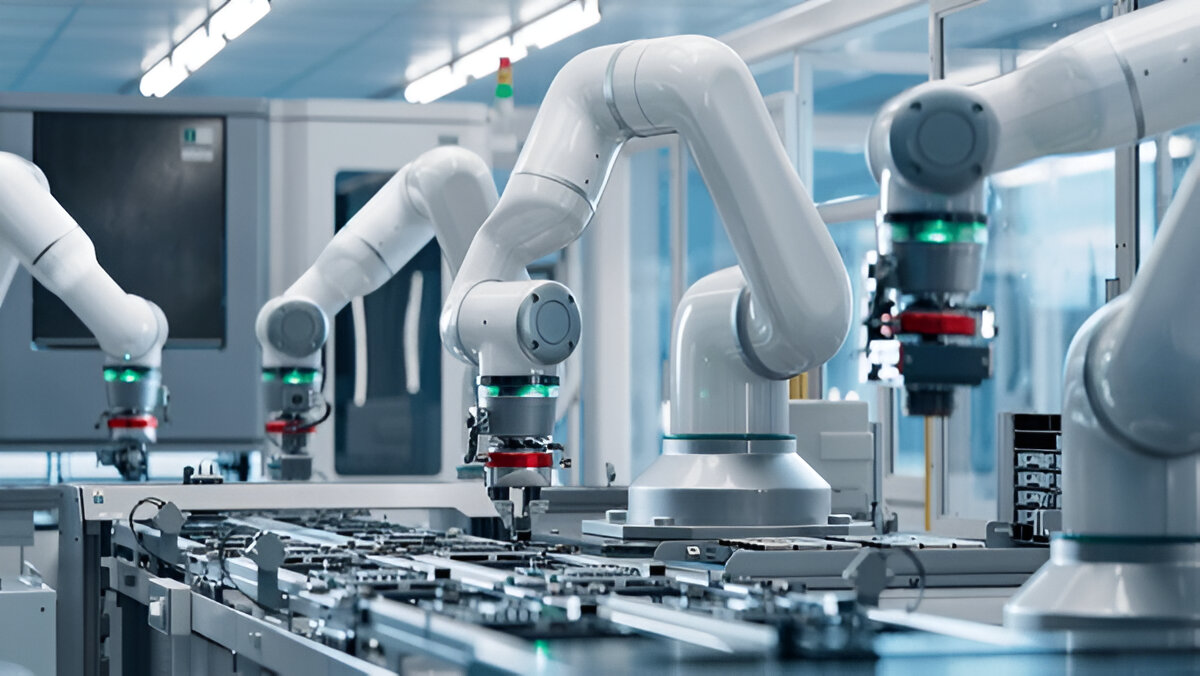

- Electronics Industry

The electronics industry requires parts that are highly precise, durable, and often miniaturized. CNC machining is widely used to manufacture components like circuit boards, connectors, casings, and other intricate parts used in devices like smartphones, computers, and other consumer electronics.

Applications in Electronics:

- Enclosures and Housings: CNC machining is used to manufacture metal or plastic enclosures that protect electronic components from dust, moisture, and physical damage. These enclosures must be both durable and aesthetically pleasing.

- Connector Parts: CNC machines are used to produce precision connectors, pins, and sockets that are essential in the functionality of electronic devices. These parts need to meet high tolerances for reliable electrical connections.

- Heat Sinks: CNC machining is used to create heat sinks that dissipate heat from electronic components such as processors and power supplies, ensuring that these components operate within safe temperature ranges.

- Prototype Development: CNC machining is an essential tool for creating prototypes of new electronic devices or components. Designers can quickly produce functional prototypes that are critical for testing and evaluation.

Benefits to Electronics:

- Precision and Detail: CNC machining offers high precision, allowing manufacturers to produce the intricate parts required in electronic devices.

- Flexibility: CNC machining is ideal for both high-volume production and small batches, making it suitable for both large-scale production and prototype development.

- Cost-Effectiveness: CNC machining reduces the need for manual labor and minimizes the risk of errors, helping to keep production costs lower.

- Consumer Goods Industry

CNC machining is extensively used in the production of consumer goods, ranging from kitchen appliances and tools to sports equipment and toys. The ability to create precise, reliable parts with a high level of consistency makes CNC machining ideal for producing high-quality products for everyday use.

Applications in Consumer Goods:

- Household Appliances: CNC machining is used to create components for household appliances such as refrigerators, washing machines, and microwaves. These parts include motor housings, gears, and other internal components that must meet strict standards for durability and performance.

- Sports Equipment: From golf club heads to bicycle frames, CNC machining is used to manufacture high-performance sports equipment. The precision of CNC ensures that these items are lightweight yet durable.

- Furniture Hardware: CNC machining is used to produce components such as drawer slides, cabinet hinges, and other furniture hardware. These parts must be precise and durable to ensure the proper functioning of furniture.

- Toys and Gadgets: CNC machining is also used to create intricate plastic or metal parts for toys, gadgets, and other novelty items. Whether it’s the casing for a remote-controlled toy or the components of a smartwatch, CNC machining ensures quality and precision.

Benefits to Consumer Goods:

- Mass Production: CNC machining allows for high-volume production, which is crucial for the consumer goods industry, where consistent quality is expected across large production runs.

- Customization: CNC technology allows manufacturers to quickly adapt to changes in design, whether it's producing custom parts or creating limited-edition products.

- Durability and Quality: With high precision and repeatability, CNC machining helps ensure the longevity and functionality of consumer goods, even in high-demand products.

- Energy Industry

The energy industry, particularly renewable energy and oil and gas, relies on CNC machining for the production of parts and components that require both strength and precision. CNC machining is used to manufacture parts for turbines, generators, valves, and other critical equipment used in the energy sector.

Applications in Energy:

- Wind Turbines: CNC machining is used to create the blades, shafts, and other components of wind turbines, where precision and material strength are crucial for performance.

- Oil and Gas Equipment: CNC machines are used to create parts for drilling rigs, pumps, and valves, all of which need to withstand extreme pressures and temperatures in harsh environments.

- Power Generation: CNC machining is used in the production of parts for power plants, including turbine blades, generator housings, and heat exchangers.

Benefits to Energy:

- Strength and Durability: Parts used in energy production must withstand extreme conditions, and CNC machining ensures that these components meet the high strength and durability requirements.

- Precision: In the energy industry, especially in areas like renewable energy, precision is key to ensuring the optimal performance of machinery and equipment.

- Customization: CNC machining allows for the production of custom parts that are designed to meet specific operational needs within the energy sector.

- Medical Device Industry

The medical device industry has very specific requirements for parts and components, particularly in areas like implants, surgical instruments, and diagnostic equipment. CNC machining is invaluable in meeting these needs, providing high precision, quality, and customization in manufacturing medical devices.

Applications in Medical Devices:

- Surgical Tools: CNC machining is used to produce precision surgical instruments, including scalpels, forceps, and tweezers.

- Orthopedic Implants: CNC machining is essential in the production of custom implants, such as hip replacements and knee joints, which require precise fitting and durability.

- Dental Devices: CNC machines are used to create dental crowns, bridges, and other restorative dental components.

Benefits to Medical Devices:

- Precision: The medical industry requires ultra-high precision, and CNC machining ensures that each part meets stringent specifications.

- Material Flexibility: CNC machines can work with biocompatible materials such as titanium, stainless steel, and medical-grade plastics, which are essential in the medical field.

- Customization: CNC technology enables the production of custom medical devices, such as personalized implants, based on patient-specific needs.

Conclusion

CNC machining is a versatile and indispensable technology used across a wide range of industries, from aerospace and automotive to medical devices and consumer goods. Its ability to produce high-precision, complex parts with minimal waste and maximum efficiency has made it the go-to solution for manufacturers around the world. Whether you’re designing custom parts for a specific application or producing high-volume runs of components, CNC machining offers the flexibility, speed, and reliability needed to meet today’s manufacturing demands.