5 Ways Zeometrix Streamlines Your Manufacturing with Instant Quotes

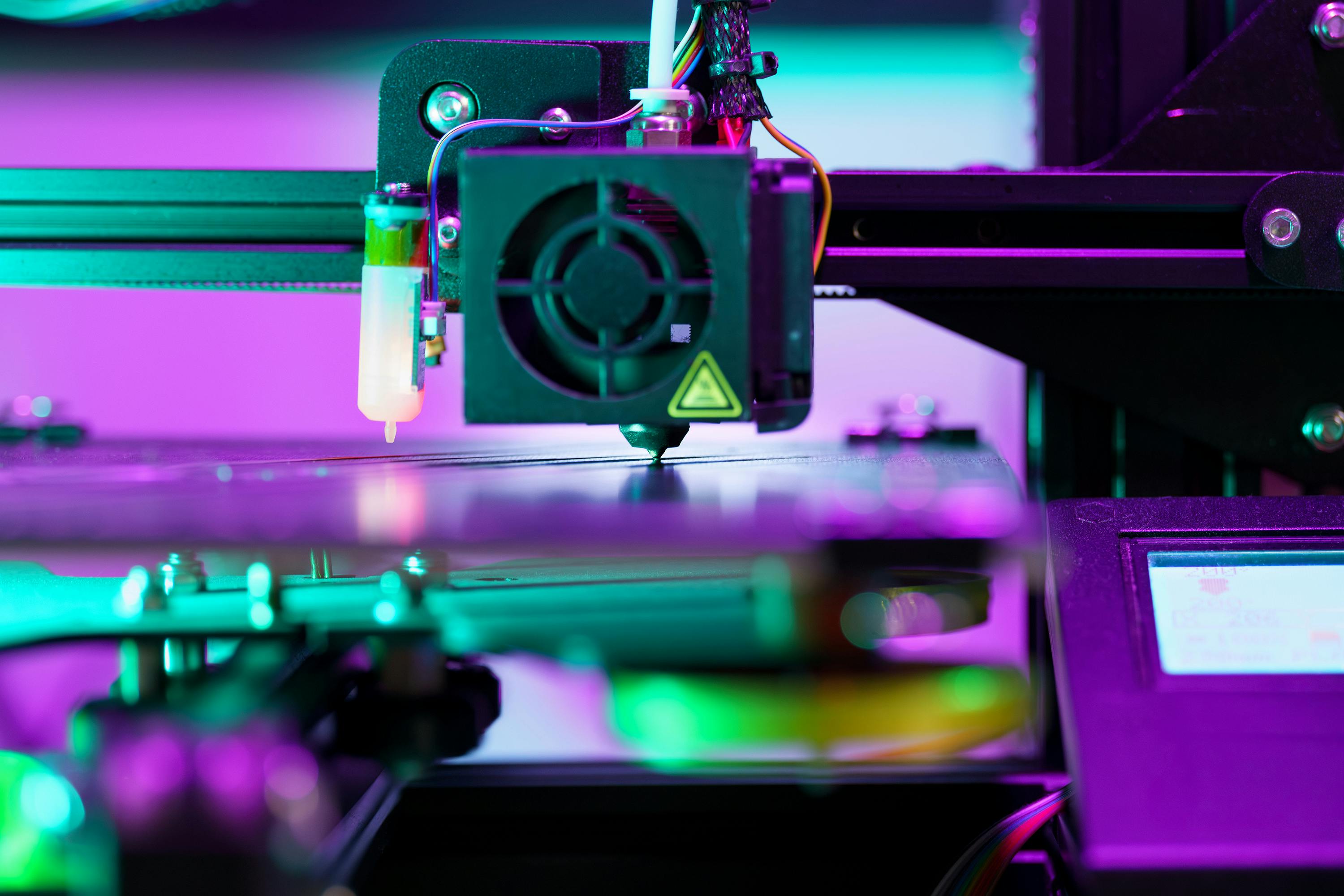

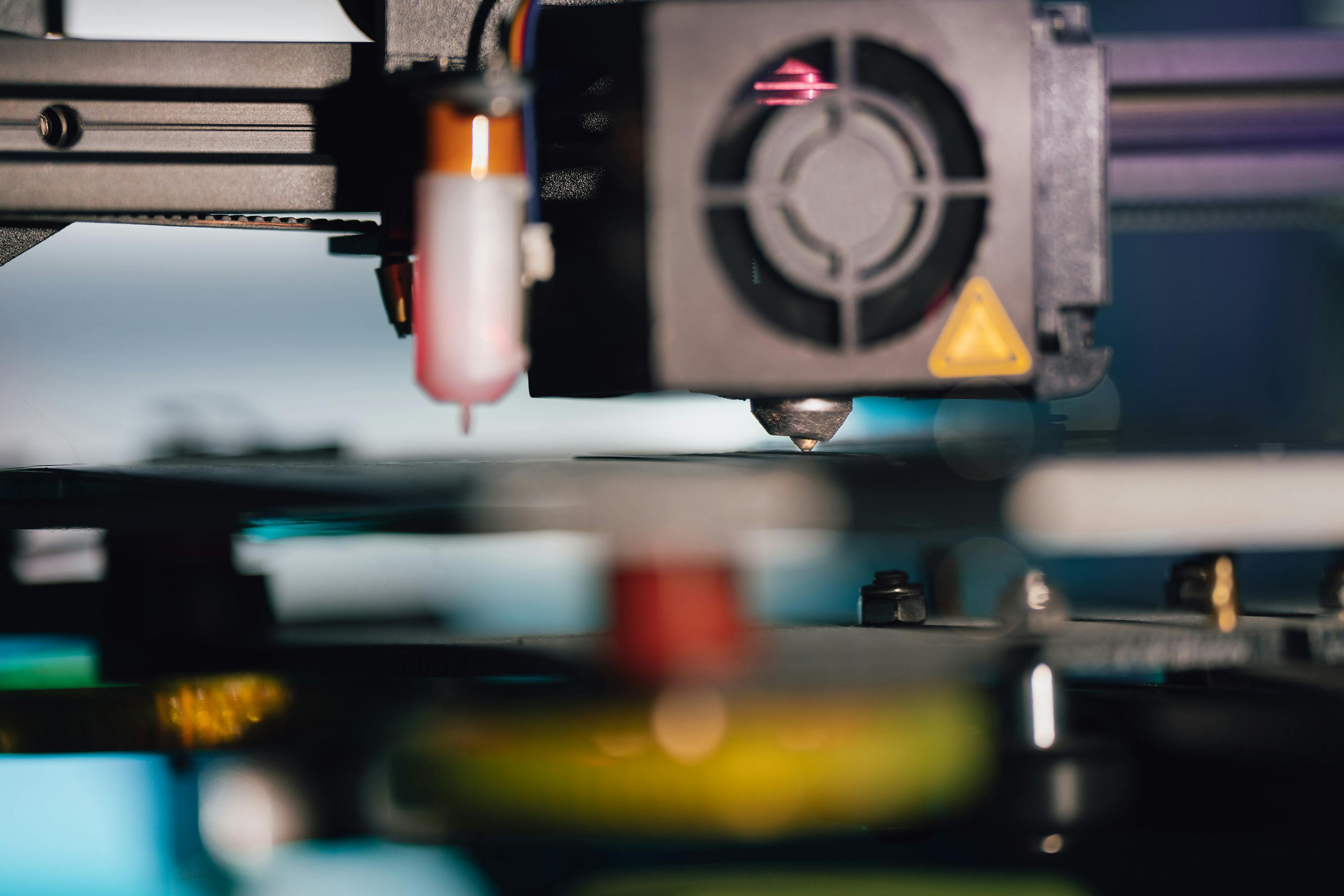

In the fast-paced world of modern manufacturing, time is money — and delays in quoting can mean missed opportunities, disrupted production schedules, and dissatisfied customers. That’s where Zeometrix stands apart. By combining cutting-edge CNC machining capabilities, a massive network of over 2,000 precision machines, and advanced quoting algorithms, Zeometrix delivers instant, accurate manufacturing quotes that help you move from concept to production faster than ever.

From tight tolerances up to 20 microns to the ability to handle a variety of materials for diverse applications, Zeometrix isn’t just a manufacturing service — it’s a next-generation production partner. In this article, we’ll explore five powerful ways Zeometrix’s instant quoting system can streamline your manufacturing operations and give you a competitive edge.

1. Lightning-Fast Turnaround with Instant Quotes

Traditional manufacturing quoting processes often involve multiple back-and-forth emails, manual cost calculations, and long waiting periods — sometimes days — before you get a number you can work with. Zeometrix replaces this outdated process with real-time quoting powered by advanced algorithms and manufacturing expertise.

-

How it works:

You simply upload your design files, specify your material, quantity, and finishing preferences, and Zeometrix’s platform instantly analyzes your requirements. -

Why it matters:

You get a precise quote in seconds instead of waiting days. This means you can finalize project budgets faster, start procurement immediately, and shorten your overall production timeline.

Example:

A client designing a prototype needed CNC-machined aluminum parts within 48 hours. Using Zeometrix’s instant quote tool, they had a confirmed cost and lead time in less than two minutes — enabling production to start the same day.

Bottom line: Instant quotes accelerate decision-making, keep projects on schedule, and help you respond to customer requests before your competitors.

2. Access to Over 2,000 Machines for Unmatched Capacity

One of the biggest bottlenecks in manufacturing is limited machine availability. If a workshop is booked out, your order may face long delays. Zeometrix solves this by connecting you to a vast network of over 2,000 CNC machines — from high-precision mills to multi-axis lathes and everything in between.

-

Scalable production: Whether you need a single prototype or a full production run, Zeometrix has the capacity to deliver without long wait times.

-

Geographic flexibility: With such a wide network, production can be distributed across facilities to reduce lead times and shipping costs.

-

Advanced capabilities: These machines can handle tight tolerances (up to 20 microns), complex geometries, and specialized materials — so your most demanding designs are achievable.

Real-world advantage:

A manufacturing firm landed a large contract requiring thousands of precision-machined components in under four weeks. Instead of struggling to scale, they used Zeometrix’s machine network to distribute production — meeting the deadline without compromising quality.

Bottom line: With Zeometrix, you’re never limited by the constraints of a single workshop.

3. Precision Engineering with Tight Tolerances up to 20 Microns

In industries like aerospace, automotive, and medical device manufacturing, precision is non-negotiable. Even a small deviation can lead to functional failures, regulatory issues, or costly recalls. Zeometrix ensures your parts meet the strictest standards by offering tolerances as tight as ±20 microns.

-

Why tolerances matter: High-precision manufacturing means your parts fit and function exactly as intended, without the need for costly rework.

-

Material versatility: Zeometrix can achieve these tolerances across a variety of metals and plastics, including aluminum, stainless steel, titanium, brass, and engineering polymers.

-

Quality assurance: Every part is subject to rigorous inspection processes to ensure consistency and compliance with your specifications.

Case in point:

A medical technology startup needed custom-machined stainless steel surgical components with extremely tight tolerances for a new product line. Zeometrix’s precision capabilities allowed them to pass stringent quality testing on the first attempt.

Bottom line: Instant quotes aren’t just about speed they’re backed by a system capable of delivering the precision your industry demands.

4. Diverse Material and Application Capabilities

Every project is unique, and your manufacturing partner should be able to handle that diversity. Zeometrix’s CNC machining network is designed for flexibility in both materials and applications.

-

Material options include:

-

Metals: Aluminum, stainless steel, mild steel, brass, copper, titanium

-

Plastics: ABS, PEEK, Delrin, Nylon, Polycarbonate

-

Specialty materials on request

-

-

Applications served:

-

Prototyping and product development

-

Aerospace components

-

Automotive parts

-

Industrial machinery

-

Medical devices

-

Consumer electronics housings

-

Why this matters:

Instead of juggling multiple suppliers for different materials or applications, you can handle everything through one platform — simplifying your supply chain and reducing administrative overhead.

Example:

An electronics manufacturer required both aluminum housings and polycarbonate internal components for a product launch. Zeometrix sourced both through its network, delivering them together, ready for assembly.

Bottom line: From material diversity to application versatility, Zeometrix’s instant quotes are backed by real-world manufacturing capabilities.

5. Streamlined Communication and Transparent Pricing

One of the most frustrating parts of traditional manufacturing is unclear pricing unexpected charges for tooling, setup, or material sourcing that appear late in the process. Zeometrix eliminates that frustration with transparent, all-inclusive instant quotes.

-

Clear breakdowns: Every quote shows material cost, machining cost, finishing cost, and delivery — so you know exactly what you’re paying for.

-

No hidden fees: What you see is what you pay, enabling accurate budgeting.

-

Centralized platform: All communication — from RFQs to production updates — happens within the Zeometrix system, keeping your projects organized and traceable.

Customer feedback example:

A product design firm praised Zeometrix for replacing long, confusing email threads with a single dashboard where they could manage quotes, track orders, and review project history in one place.

Bottom line: Instant quotes are just the start — the platform keeps your projects running smoothly from start to finish.

Why Zeometrix Is Changing the Game in Manufacturing

By combining speed, capacity, precision, material diversity, and transparent pricing, Zeometrix redefines what’s possible in manufacturing. The instant quoting system is more than a convenience — it’s a strategic advantage in an industry where time and accuracy are critical.

When you choose Zeometrix, you’re getting:

-

Faster time-to-market

-

Scalable production resources

-

Precision engineering for high-demand industries

-

A one-stop solution for multiple materials and applications

-

Predictable costs with no surprises

Getting Started with Zeometrix’s Instant Quote System

Ready to see the difference for yourself? Here’s how simple it is:

-

Upload your CAD files – Supported in multiple formats.

-

Select materials, quantities, and finishes – Choose from our extensive list.

-

Receive your instant quote – In seconds, with no obligation.

-

Approve and start production – Your order is assigned to the best-suited machine in our network.

-

Receive your parts – Delivered on time, every time.

It’s manufacturing made smarter, faster, and more predictable.

Final Thoughts

The manufacturing landscape is evolving, and companies that embrace automation, precision, and speed will lead the market. With its instant quote system, expansive machine network, and proven ability to deliver tight-tolerance parts in record time, Zeometrix is helping manufacturers reduce lead times, improve quality, and stay competitive.

If you’re tired of waiting days for quotes and weeks for production, it’s time to discover a better way.

Experience the Zeometrix advantage today — where manufacturing meets speed, precision, and innovation.