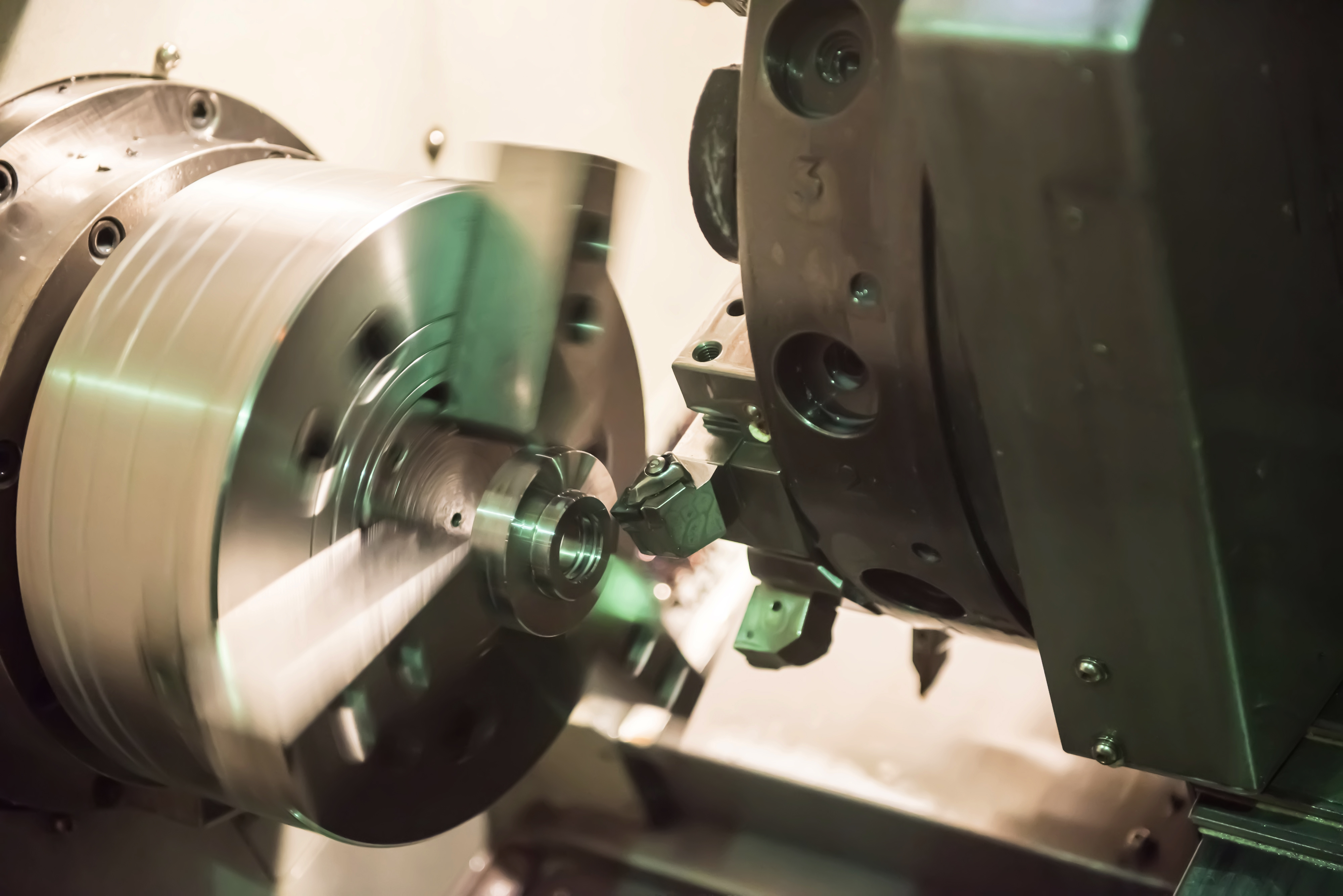

Top CNC Machining Services in Bangalore for Precision Engineering

In the world of modern manufacturing, precision, reliability, and repeatability are non‑negotiable. Complex designs, tight tolerances, and demanding performance often hinge on the quality of the machining partner you choose. If you’re looking for top‑tier Top CNC Machining Services in Bangalore for Precision Engineering

CNC machining services in India, Bangalore is emerging as one of the most important hubs — combining technical capability, infrastructure, skilled workforce, and cost competitiveness. In this article, we’ll explore what makes CNC machining in Bangalore stand out, key players, what you should look for, and how to select the best service provider for precision engineering requirements.

Why Bangalore for Precision CNC Machining?

Before examining specific companies, it’s worth looking at the strengths of Bangalore as a location for high‑precision CNC services. Several factors make the city particularly well suited:

- Industrial Infrastructure & Clusters

The city has established industrial zones such as Peenya Industrial Area, which houses many CNC machine shops, tool & die firms, jigs & fixtures, and related sub‑contract industries. This clustering enables supply chains for raw materials, tooling, finishing services, metrology, etc., to be more accessible. - Availability of Skilled Workforce

Bangalore is an engineering and tech education center. There is a steady stream of mechanical engineers, CNC programmers, machinists, and quality control experts who are familiar with modern CAD/CAM, CAM strategies, and metrology tools. The presence of research institutes and technical training centers helps sustain this talent base. - Technology & Machine Capability

Many CNC machining companies in Bangalore are equipped with advanced machines (multi‑axis CNC milling, high‑precision turning, sliding head machines, VMCs, etc.), and complement these with modern inspection tools (like CMMs, roundness, surface roughness measurement, etc.). - Diverse Industries & High Standards

Bangalore’s industrial base includes automotive, aerospace, medical devices, defence, energy, electronics, etc. These sectors typically demand high precision and strict quality standards (ISO/AS safety, surface finish, tolerances). Service providers in Bangalore have to adhere to these standards to be competitive, which raises the overall quality. - Cost & Lead Time Advantages

While Bangalore is not the lowest‑cost region in India, the blend of competitive labor, established suppliers, optimized logistics, and familiarity with precision machining workflows often yields better value, especially for complex parts or small batches, when compared to many alternatives. Also, the proximity to raw material distributors, finishing shops, etc., reduces delays.

What Precision Engineering Requires from CNC Machining

To understand what “top CNC machining services” means in this context, below are key capabilities and criteria that matter when the target is precision engineering:

|

Feature |

Why It Matters |

|

Machine Accuracy & Stability |

High‑rigidity, well maintained machines give consistent dimensional accuracy and surface finish. Thermal stability, spindle run‑out, proper calibrations all contribute. |

|

Multi‑Axis and Complex Machining |

Complex components often require more than simple 3‑axis milling or standard turning. 4‑ or 5‑axis milling, sliding head turning, Swiss‑type CNC, turn‑mill centers allow fewer setups, more accuracy, and complex geometries. |

|

Material Expertise |

Different materials (aluminum, stainless steel, high strength alloys, titanium, plastics etc.) machine differently. Expertise with tooling, cooling, feeds & speeds for these materials is essential. |

|

Quality Control / Inspection |

Tolerances often in microns; surfaces need specific finishes. Accurate metrology tools – CMMs, roundness testers, profilometers, etc. Process controls to ensure first piece, in‑process, and final inspections. |

|

Prototyping / Small Batch to Large Volume |

Precision engineering often starts with prototypes, test batches, then scales. The machining partner must be flexible in volumes while maintaining quality. |

|

Certifications & Compliance |

ISO certifications, aerospace standards (e.g. AS9100), medical device quality norms, defense‑grade approvals where applicable. This assures that parts will be accepted downstream. |

|

Lead Time, Reliability, & Communication |

Even perfect precision is useless if deliveries are delayed or changes are not communicated. Good project management, feedback loops, and realistic quoting are critical. |

Top CNC Machining Service Providers in Bangalore

Here are some of the companies in Bangalore that are often cited for high‑precision CNC machining. These firms exemplify many of the qualities just discussed.

|

Company |

What They Offer / Strengths |

|

Giromill Precision Pvt. Ltd. |

Offers high‑precision CNC turning, milling, grinding; serves aerospace, defense, automotive, industrial machinery. Strong capability in custom components, process design, strict QC. |

|

Esskay Precision Engineering |

Known for precision components, assemblies & sub‑assemblies; equipment includes CNC turning, CNC milling, CNC grinding; comprehensive QC; serves automotive, hydraulics, power tools. |

|

Sri Manjunatha Precision Works |

Over 30 years in the business; strong in sectors with very high precision demands including aerospace, medical, defence; capabilities include CNC Sliding Head, VMC machines, Automat machining, etc. |

|

Fine Punch Fab Pvt Ltd |

Offers custom prototyping, CNC milling, turning, batch production; works with metals and plastics; emphasizes on‑time delivery and customer collaboration. |

|

Epsilon Engineering |

Known for five‑axis machining, VMC fixtures, CNC prototyping, short lead times, ability to handle complicated shapes with good tolerances. |

|

Unnathi CNC Technologies Pvt. Ltd. |

Has multiple CNC machining and turning centers; with grinding, turn‑mill capabilities; experience and infrastructure to handle precision machining. |

|

Precision Engineering Products Pvt. Ltd. |

Long heritage; started in earlier decades; specialized turned components and machined parts; has transitioned over time into more advanced machining operations. |

These companies represent a cross‑section of the kinds of capabilities available in Bangalore — you’ll find ones more focused on prototyping vs. high‑volume, or general engineering vs. highly regulated sectors like aerospace or medical.

Case Study: Meeting High‑Precision Needs in Aerospace and Medical

To illustrate what it takes, consider aerospace or medical components. These applications demand:

- Tolerances often in the range of ±0.01 mm or tighter

- Surface finishes that may require specific roughness values

- Materials that are difficult to machine (e.g. titanium, Inconel, high‑grade stainless steels)

- Multistage qualification, including material certifications, process traceability, possibly clean room conditions

One company in Bangalore, Sri Manjunatha Precision Works, offers sliding head, turn‑mill, automat machining and has decades of experience in aerospace & defence medical sectors. Because of their mature quality systems, they are suited to delivering parts that satisfy those high regulatory demands.

Similarly, Unimech Aerospace, based in Peenya, is another firm that has an explicitly aerospace focus, with significant facility size, quality infrastructure (CMM etc.), large machining ranges, capable of fabricating big components.

These examples show that with the right partner in Bangalore, you can get precision engineering‑level parts, not just basic CNC jobs.

How to Choose the Right CNC Machining Partner in Bangalore

Given several capable companies, how do you choose the one that best matches your needs? Here are decision‑making steps & criteria:

- Define Your Requirements Clearly

- Dimensional tolerances required

- Surface finish

- Material type

- Volume (prototype, low volume, high volume)

- Regulatory or certification needs (if any)

Having detailed CAD drawings, material specs, and finish requirements will help the vendor quote accurately.

- Check Machine Capabilities

- Does the shop have the necessary machine types (multi‑axis milling, sliding head, turn‑mill, etc.)

- Are the machines recent / well maintained

- Cooling, tool‑holding, thermal stability of machine shop

- Inspect Quality Systems

- In‑process inspection, final inspection capability

- Tools like CMMs, roundness/testers, surface finish equipment

- Certifications (ISO, AS, etc)

- Track record in similar industries

- Review Past Projects & References

- Samples or case studies of similar complexity or industry

- Talk to their clients if possible

- Delivery history: Did they meet timelines?

- Analyze Lead Time & Communication

- How quickly they can go from quote to first part

- Responsiveness to design changes or feedback

- Transparency in quoting (do they factor in all cost elements, tools, setups, finishing etc.)

- Pricing vs Value

- Lowest cost is rarely the best if precision, quality, and delivery suffer

- Consider overall cost: If re‑work, part failure, or poor finish happen, the indirect cost is high

- Support & After‑Sales

- If you have iterative product development, you’ll want a partner willing to do prototyping, adjustments

- Warranties or guarantees for machining defects, dimensional drift, etc.

Challenges & How Bangalore Firms Are Overcoming Them

Even with many strengths, there are challenges in precision Top CNC Machining Services in Bangalore for Precision Engineering. But many firms are addressing them:

- Machine Maintenance & Calibration: Over time machine wear, thermal effects, spindle drift can degrade precision. Top firms schedule periodic maintenance, recalibration, environmental control.

- Skilled Labor Shortage for very high precision work: Machinists capable of working at micron‑levels are rare. Some companies invest in training, cross‑skilling.

- Supply Chain Delays or Material Variability: If raw materials are delayed or inconsistent in grade, surface etc., this affects outputs. Firms mitigate this by maintaining strong supplier networks, & inspecting raw materials.

- Competition from Overseas & Automation Pressure: As global players automate more, cost & precision expectations rise. Some Bangalore firms are investing in more automation, smart machining, integrating IoT, digital monitoring to improve throughput without sacrificing quality.

.jpg)

Tips for Getting the Top CNC Machining Services in Bangalore for Precision Engineering

If you are a customer (engineer, designer, product manager, entrepreneur) looking to use CNC machining services in Bangalore, here are some best practices:

- Provide Complete Technical Package: CAD/CAM files, 3D models (if possible), material specs, tolerance tables, surface finish expectations, even assembly or mating features. The more precise the input, the better the output.

- Prototype First: For critical parts, get a prototype or pre‑production batch. Evaluate fit, finish, performance. Adjust tolerances or designs if needed before scaling.

- Design for Manufacturability (DfM): Simple design changes (e.g. reducing number of setups, optimizing tool paths, avoiding overly small or hard‑to‑access features) can reduce machining time, risk, and cost. Ask your machining partner for suggestions.

- Schedule Inspections Early: Early inspections (first part, mid batch) to detect issues before they propagate through full production.

- Plan for Finishing & Post‑Processing: Surface treatments, plating, heat treatments, polishing etc., are often needed. It helps if your machining partner has access to or can coordinate with reliable finishing shops.

- Allow Some Margin in Time & Budget: Precision work often has unforseen delays – tool wear, rework, inspection issues. Build buffers.

-

Outlook: Future of Precision CNC Machining in Bangalore

The next few years look promising for Bangalore as a precision engineering hub. Some trends to watch:

- Increased adoption of multi‑axis machines (5‑axis, 6‑axis) and hybrid machining to reduce setup times and improve geometries.

- Integration of Industry 4.0 practices: real‑time monitoring, predictive maintenance, process traceability, digital twins.

- More specialization in high‑regulation sectors like medical devices, aerospace, defence; firms will need stricter traceability, possibly certifications like NADCAP, regulatory clearances etc.

- Growth in additive + subtractive hybrid manufacturing (3D printing + CNC finishing) for complex geometries.

- Rising demand from EVs, aerospace composites, micro‑machining which will push tolerances, surface finishes, and material challenges higher.

-

If your project demands precision, repeatability, and engineering rigor, Bangalore offers a rich ecosystem of CNC machining services equipped to deliver. With multiple firms offering state‑of‑the‑art capabilities — from prototyping to high‑volume production, from simple turned parts to complex 5‑axis geometries— you can find partners that meet exacting standards.

The key is to match your project’s specific needs (tolerances, materials, inspections, regulatory requirements) with a service provider that has proven capabilities in that niche. When you do this, you get not just parts—but precision engineered assets that perform reliably, reduce downstream risk, and contribute to your competitive edge.