What Is Production CNC Machining? A Comprehensive Guide

In today’s highly competitive manufacturing environment, precision, speed, and scalability are crucial. One technology that embodies these qualities and has revolutionized the production of complex parts is CNC machining. When this technology is leveraged for high-volume manufacturing, it is known as production CNC machining — a process critical for industries that demand large quantities of precision components.

This comprehensive guide explores every aspect of production CNC machining — from its fundamental concepts to advanced applications — helping engineers, manufacturers, and curious readers understand why it plays a pivotal role in modern manufacturing.

Introduction to CNC Machining

What Is CNC Machining?

CNC stands for Computer Numerical Control. CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This automated control allows machines to carry out complex cuts and shapes on raw materials with extreme precision and repeatability.

Unlike traditional manual machining, where skilled operators physically guide the tools, CNC machining uses digital instructions to operate the cutting tools. This not only improves accuracy but also enables complex geometries that would be impossible or impractical manually.

Historical Context

CNC machining originated in the 1940s and 50s as an evolution from numerical control (NC) machines. Early CNC systems used punch cards and basic digital controls, while modern machines integrate advanced computing power, sensors, and software to enhance capabilities and efficiency.

Understanding Production CNC Machining

Definition

Production CNC machining refers to the use of CNC machines to manufacture large quantities of identical or nearly identical parts. While CNC machining can be used for one-off prototypes or small batches, production machining focuses on scalability, consistency, and efficiency for mass manufacturing.

Key Characteristics

- High Volume: Production runs can range from hundreds to hundreds of thousands of parts.

- Repeatability: Each part must meet exact specifications with minimal variation.

- Efficiency: Cycle times are optimized to maximize throughput.

- Automation: Utilizes robotics and automated handling systems for continuous operation.

- Quality Assurance: Incorporates rigorous inspection and feedback loops to maintain standards.

Why Production CNC Machining?

Manufacturers choose production CNC machining when parts require high precision and quality but cannot be economically produced through stamping, casting, or injection molding, especially for mid-sized runs or complex geometries.

Step-by-Step Process of Production CNC Machining

Let’s dive deeper into the workflow that transforms raw materials into finished parts in a production CNC environment.

a. Design and Engineering

The process begins with engineering teams creating a 3D model of the part using CAD (Computer-Aided Design) software. This model includes every dimension, tolerance, and surface finish specification required.

Example: An aerospace company designs a lightweight titanium bracket with intricate holes and curves for an aircraft assembly.

b. Toolpath Programming with CAM

The CAD file is imported into CAM (Computer-Aided Manufacturing) software, which converts the design into toolpaths — instructions dictating the exact movements of cutting tools.

Experienced programmers optimize these toolpaths to minimize cutting time, reduce tool wear, and avoid collisions, particularly important for production runs.

c. Material Selection and Preparation

Material selection depends on part requirements such as strength, weight, corrosion resistance, and cost. Raw materials come as rods, billets, bars, or sheets.

Example: For the aerospace bracket, titanium alloy is chosen for its strength-to-weight ratio.

d. Machine Setup and Fixturing

Precision fixturing is critical in production to hold the parts firmly and consistently. Automated pallet changers and multi-part fixtures enable the machine to operate unattended for extended periods.

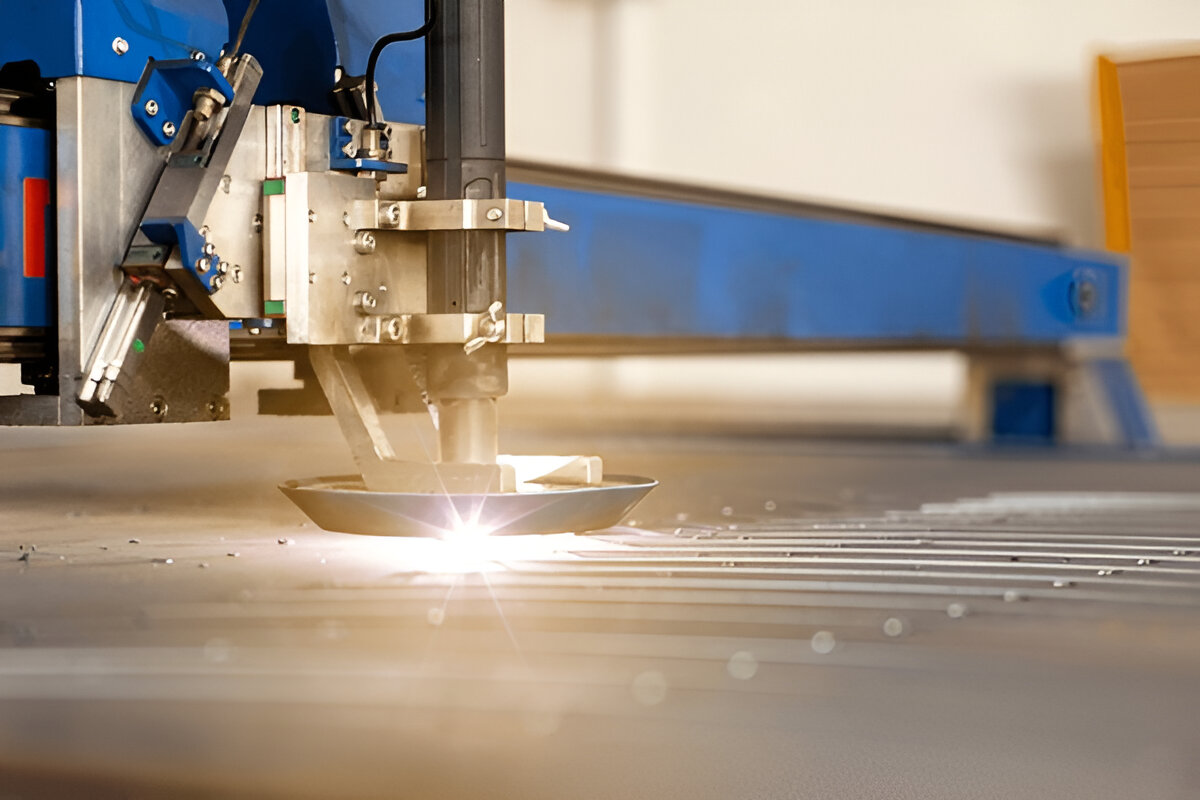

e. Machining Execution

The CNC machine executes the toolpaths to cut, drill, mill, or turn the workpiece into the desired shape. Multi-axis machines can create complex geometries in fewer steps, increasing efficiency.

Advanced machines may use multiple spindles or simultaneous multi-tool operations to speed up production.

f. In-Process Monitoring

Sensors and probing systems monitor the machining process in real-time. Data on tool wear, temperature, and vibrations helps prevent defects and optimize performance.

g. Quality Inspection

Post-machining inspection ensures parts meet stringent tolerances. Coordinate Measuring Machines (CMMs) scan the parts, comparing them to the original CAD model.

Statistical Process Control (SPC) charts track quality trends throughout the production run, catching any deviation early.

h. Post-Processing

Depending on the requirements, parts may undergo finishing operations like deburring, anodizing, heat treatment, or coating.

i. Packaging and Delivery

Finished parts are carefully packaged to avoid damage and shipped to customers or assembly lines.

Types of CNC Machines Used in Production

a. CNC Milling Machines

Milling machines use rotary cutters to remove material. They can work on 3-axis (X, Y, Z) or more advanced 4-axis and 5-axis machines that add rotational movement to the cutting tool or the workpiece.

Use Cases: Complex aerospace parts, automotive components, medical devices.

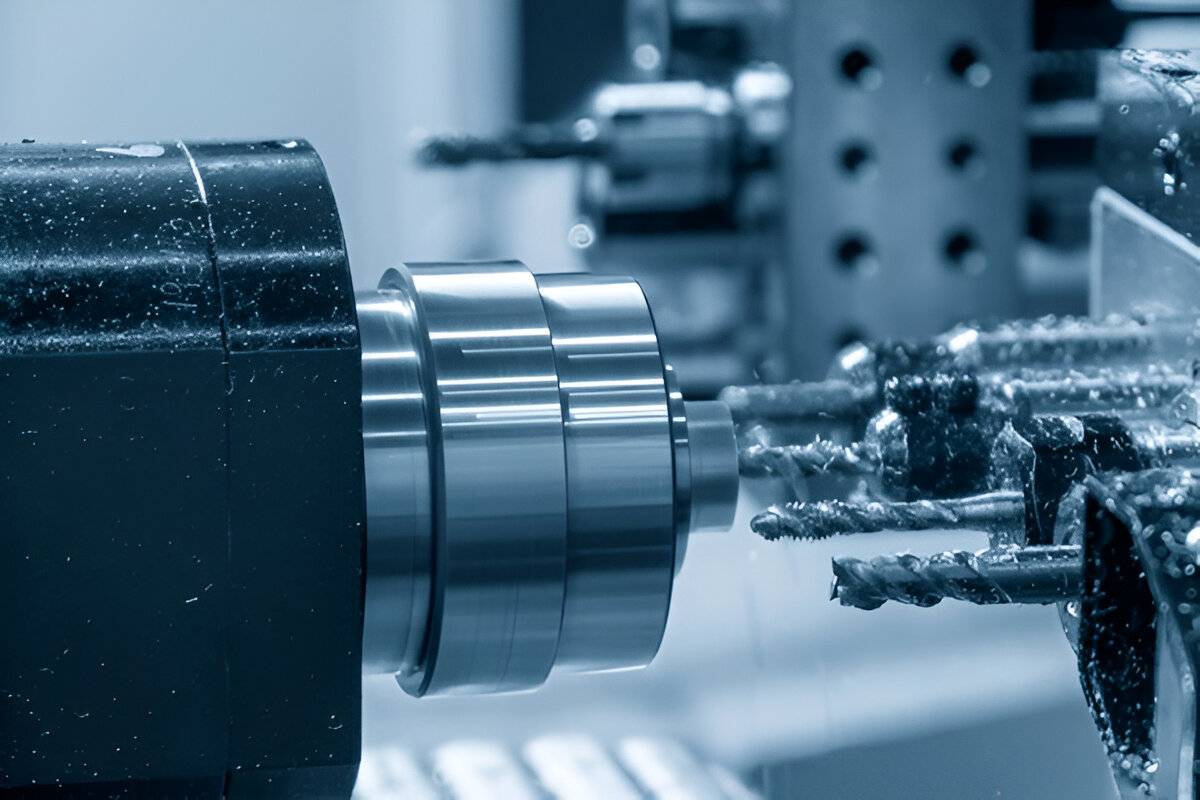

b. CNC Lathes

Lathes rotate the workpiece while a stationary tool removes material, perfect for cylindrical parts like shafts, bolts, or bushings.

Use Cases: Automotive axles, medical implants, fasteners.

c. Swiss-Type CNC Machines

These are specialized lathes used for small, precise parts. They support bar feeding and multiple tools operating simultaneously.

Use Cases: Medical device components, electronic connectors.

d. Multi-Spindle and Multi-Turret Machines

Machines with several spindles or turrets work on multiple parts or multiple features on a part at once, dramatically increasing output.

Use Cases: High-volume fastener production, automotive components.

e. CNC Routers

Best for softer materials like plastics, composites, and wood. Often used for cutting large panels or mold prototypes.

Materials Commonly Machined in Production

Metals

- Aluminum: Lightweight, corrosion-resistant, easily machined.

- Steel: High strength, available in carbon, alloy, and stainless varieties.

- Titanium: Excellent strength-to-weight ratio, corrosion-resistant but challenging to machine.

- Brass & Copper: Excellent conductivity and machinability.

- Magnesium: Lightweight but requires special handling.

Plastics

- ABS: Durable, impact-resistant.

- Nylon: Good strength and chemical resistance.

- Delrin (Acetal): High stiffness and low friction.

- PEEK: High performance, used in aerospace and medical.

Composites

- Carbon Fiber: Lightweight and strong, but abrasive to tools.

- Fiberglass: Often used in automotive and marine applications.

Benefits of Production CNC Machining

Precision and Accuracy

CNC machines can maintain tolerances within microns, critical for high-performance parts.

Consistency and Repeatability

Identical parts can be produced over long production runs without variation.

Flexibility and Scalability

Quickly adapt to design changes or scale production volume without expensive tooling changes.

Reduced Lead Time

Rapid programming and setup allow quicker turnaround compared to traditional methods.

Material Optimization

Advanced toolpaths and machining strategies minimize waste and reduce raw material costs.

Automation Reduces Labor Costs

Automated tool changers, pallet systems, and robotic loading reduce manual intervention.

Real-World Applications and Industry Use Cases

Aerospace

Parts like turbine blades, engine mounts, and complex airframe components require high precision and reliability. CNC machining allows manufacturing with exotic alloys like Inconel and titanium.

Automotive

Engine components, transmission parts, and suspension components are often produced using CNC machining for durability and performance.

Medical

Implants, surgical instruments, and prosthetics demand extremely tight tolerances and biocompatible materials.

Electronics

Precision housings, connectors, and cooling components are machined from metals and plastics.

Consumer Goods

Sporting equipment, custom tools, and luxury watches leverage CNC machining for quality and detail.

Challenges and Critical Considerations

High Initial Investment

CNC machines, especially advanced multi-axis or multi-spindle models, are capital intensive.

Skilled Programming Required

Optimizing toolpaths and cycle times requires experienced CAM programmers.

Tool Wear and Maintenance

Machining hard materials accelerates tool wear, necessitating frequent tool changes and machine maintenance.

Quality Control Complexity

Maintaining consistent quality across thousands of parts demands robust inspection systems and process control.

Material-Specific Issues

Some materials require coolant management, specialized tooling, or slower feed rates.

Cost Factors in Production CNC Machining

- Setup Costs: Fixture design, programming, and machine preparation.

- Material Costs: Raw materials can vary widely based on type and grade.

- Cycle Time: Faster machining reduces per-part costs but may require advanced tools.

- Labor: Skilled operators and programmers add to costs.

- Tooling: Cutting tools wear and must be replaced regularly.

- Quality Control: Inspection and scrap rates affect overall efficiency.

Balancing these factors is key to cost-effective production machining.

Future Trends and Innovations

Automation and Robotics Integration

Fully automated production lines reduce downtime and labor costs, enabling 24/7 operation.

Artificial Intelligence

AI-driven adaptive machining optimizes toolpaths and parameters in real-time based on sensor data.

Hybrid Manufacturing

Combining additive manufacturing (3D printing) with CNC machining enables producing parts with complex internal structures.

Industry 4.0 and Smart Factories

IoT-enabled machines provide real-time monitoring, predictive maintenance, and data-driven optimization.

Advanced Materials and Coatings

Development of new alloys and protective coatings enhances machinability and part performance.

Deep Dive: CNC Machine Components and Operation

Understanding the inner workings of CNC machines helps appreciate their precision and capability in production environments. A typical CNC machine consists of several key components working in harmony:

a. Machine Frame and Bed

The machine frame provides the structural foundation, often made from heavy cast iron or steel to minimize vibrations and ensure stability during cutting. A stable frame is essential for maintaining tight tolerances over long production runs.

b. Spindle

The spindle holds the cutting tool and spins at high speeds—ranging from a few thousand to tens of thousands of RPM (revolutions per minute). Modern CNC machines have variable speed spindles controlled via software, allowing adjustment depending on the material and cutting operation.

c. Axis and Drive Systems

Production CNC machines operate along multiple axes—commonly X, Y, and Z, with more advanced models offering rotational axes like A and B. Each axis moves via precision ball screws, linear guides, and servo motors, precisely positioning the tool or workpiece within microns.

d. Control Unit

This is the brain of the machine, running the CNC program that tells the machine how to move. The control unit interprets G-code instructions and coordinates all components, from axis movements to spindle speed and coolant application.

e. Tool Changer

For production, machines typically have automatic tool changers (ATCs) holding multiple cutting tools. The machine automatically swaps tools during machining to perform different operations without manual intervention, dramatically reducing cycle time.

f. Coolant System

Machining generates heat, which can damage tools and parts if uncontrolled. Coolant systems spray liquids or mist to reduce heat, flush away chips, and improve tool life.

g. Workholding Fixtures

For production machining, repeatable workholding is critical. Fixtures securely clamp parts in the exact same position for each cycle, ensuring consistent quality.

Quality Control and Inspection in Production CNC Machining

Maintaining stringent quality standards over thousands of parts requires sophisticated inspection and quality assurance protocols.

In-Process Inspection

Some production CNC machines are equipped with in-process probing systems. These probes measure part features during machining, providing immediate feedback. If deviations are detected, the machine can adjust cutting parameters or halt the operation to prevent producing defective parts.

Statistical Process Control (SPC)

SPC involves collecting data on part dimensions during production and analyzing trends to detect variations before they lead to quality issues. Control charts track parameters such as hole diameter, surface finish, or flatness, allowing operators to intervene early.

Coordinate Measuring Machines (CMM)

Post-production, parts are often measured using CMMs, which use a touch probe to scan parts in 3D and compare dimensions against the CAD model. High-precision CMMs can detect deviations down to microns, ensuring parts meet specifications.

Automated Optical Inspection (AOI)

AOI systems use cameras and lasers to quickly inspect parts for surface defects, dimensional accuracy, and completeness. For high-volume production, AOI accelerates quality checks without slowing production.

Traceability and Documentation

Production CNC machining often requires full traceability for quality audits, especially in regulated industries like aerospace and medical. Systems track machine settings, operator data, tool wear, and inspection results for every batch.

The Role of Automation in Production CNC Machining

Automation dramatically transforms production CNC machining by increasing throughput, reducing labor costs, and improving consistency.

Robotic Loading and Unloading

Robotic arms can load raw materials and unload finished parts from CNC machines autonomously. This allows machines to run continuously, even overnight, increasing production capacity.

Pallet Systems

Pallet changers enable quick switching of workpieces. While one part is being machined, another pallet can be loaded or unloaded, minimizing downtime between cycles.

Automated Tool Management

Sensors monitor tool wear and automatically change worn tools. This reduces human error and ensures machining quality is maintained.

Integration with Manufacturing Execution Systems (MES)

Advanced factories integrate CNC machines into MES software for real-time production scheduling, monitoring, and quality control. This integration streamlines workflows and reduces bottlenecks.

Sustainability and Environmental Impact

As manufacturing industries aim for greener processes, production CNC machining offers several sustainability advantages:

- Material Efficiency: CNC removes only the necessary material, minimizing waste compared to casting or forging.

- Tool Life Extension: Advanced coatings and coolant systems extend tool lifespan, reducing consumable waste.

- Energy Consumption: Modern CNC machines optimize energy use, and factories increasingly source renewable power.

- Recyclability: Scrap materials, especially metals, are often recyclable, enabling closed-loop manufacturing.

However, machining processes still consume energy and coolant fluids, and managing waste responsibly remains a priority.

Tips for Optimizing Production CNC Machining

- Invest in Proper Fixturing: Well-designed fixtures reduce setup time and improve repeatability.

- Use High-Quality Tools: Carbide and coated tools improve cutting performance and reduce wear.

- Optimize CAM Programs: Simulate and refine toolpaths to reduce cycle times and avoid collisions.

- Implement Regular Maintenance: Preventative maintenance avoids costly downtime.

- Train Skilled Operators: Experienced operators can troubleshoot issues and improve processes.

- Monitor Data: Use machine data and SPC to continuously improve quality and efficiency.

Conclusion

Production CNC machining is a critical manufacturing process for producing high-quality, precise parts in medium to large volumes. Its combination of automation, accuracy, and flexibility makes it suitable across various industries, including aerospace, automotive, medical, and electronics.

Understanding the workflow, machinery, material options, and challenges of production CNC machining enables manufacturers to make informed decisions and optimize their processes. With continual technological advances, CNC machining will remain at the forefront of manufacturing innovation, driving efficiency and quality for years to come.