What Is CNC Machining Prototyping? Everything You Need to Know

In today’s fast-paced manufacturing world, the ability to quickly develop, test, and refine product designs is more critical than ever. Whether you are an entrepreneur, engineer, or product designer, understanding the tools and processes that bring your ideas from concept to reality is essential. One such indispensable technology is CNC machining prototyping.

This blog will take you through everything you need to know about CNC machining prototyping, including what it is, how it works, its benefits, applications, and how to find the right provider offering custom CNC services or CNC manufacturing near me.

What is CNC Machining Prototyping?

CNC machining prototyping is the process of creating a prototype—a preliminary model of a product—using computer numerical control (CNC) machining techniques. CNC machining involves using computerized controls and machine tools to remove material from a solid block (metal, plastic, wood, or composites) to form a precise part or component.

Prototyping is a crucial stage in product development, allowing designers and engineers to evaluate a product's form, fit, function, and performance before committing to mass production. CNC machining prototyping helps bridge the gap between design and manufacturing by providing an accurate, functional prototype that closely replicates the final product.

In essence, CNC machining prototyping combines digital design precision with manufacturing flexibility to deliver high-quality prototypes efficiently.

How Does CNC Machining Prototyping Work?

The process of CNC machining prototyping involves several key steps:

Step 1: Design Creation

A digital 3D model of the part is created using Computer-Aided Design (CAD) software. This model contains all the dimensions, geometries, and features needed for the final part.

Step 2: Conversion to CNC Program

The CAD file is converted into a CNC-compatible format using Computer-Aided Manufacturing (CAM) software. CAM software generates the toolpaths that the CNC machine will follow to cut or mill the material.

Step 3: Material Selection

Depending on the prototype requirements, an appropriate raw material is selected. This can range from various metals like aluminum or steel to plastics such as ABS or polycarbonate.

Step 4: CNC Machining

The CNC machine follows the programmed toolpaths to cut, drill, mill, or turn the material, gradually shaping it into the prototype part. CNC machines use different tools, such as end mills, drills, and lathes, to achieve the desired shape and precision.

Step 5: Finishing

Once machining is complete, the prototype may undergo finishing processes like sanding, polishing, painting, or coating to enhance surface quality and appearance.

Step 6: Inspection and Testing

The prototype is inspected for dimensional accuracy and tested for functionality to ensure it meets the design specifications and performance criteria.

This workflow ensures that the prototype accurately represents the final product, enabling effective validation and iteration.

Advantages of CNC Machining for Prototyping

CNC machining prototyping offers several benefits that make it a preferred choice for product development:

Precision and Accuracy

CNC machines operate with micrometer-level accuracy, producing prototypes with tight tolerances that are often impossible to achieve with manual machining or other prototyping methods.

Material Versatility

Unlike some rapid prototyping methods limited to plastics or resins, CNC machining can work with a wide range of materials—including metals, plastics, and composites—allowing you to test prototypes in real-world conditions.

Speed and Efficiency

Modern CNC machines can rapidly produce complex parts with minimal human intervention, speeding up the prototyping phase without compromising quality.

Functional Prototypes

Because CNC machining removes material from solid blocks, the resulting prototype can be strong and durable enough for functional testing, unlike some additive manufacturing prototypes that may be too fragile.

Scalability

Prototypes produced via CNC machining can easily be scaled up to small batch production runs or full manufacturing, often using the same processes and tooling.

Customization

With custom CNC services, you can tailor the prototype to very specific requirements, including complex geometries, multiple materials, or integrated components.

Common Materials Used in CNC Prototyping

Selecting the right material is crucial for prototype performance and accuracy. Common materials used in CNC machining prototyping include:

Metals

- Aluminum: Lightweight, corrosion-resistant, and easy to machine. Ideal for aerospace, automotive, and consumer electronics prototypes.

- Stainless Steel: Durable and resistant to wear and corrosion. Used in medical devices and industrial equipment.

- Brass: Good for prototypes requiring low friction and good electrical conductivity.

- Titanium: Strong and lightweight, often used in aerospace and medical implants.

Plastics

- ABS: A strong and impact-resistant plastic commonly used for consumer products and automotive parts.

- Polycarbonate (PC): High strength and excellent transparency, used for safety equipment and lenses.

- Nylon: Good for mechanical parts due to its toughness and flexibility.

- Delrin (Acetal): Known for its low friction and high stiffness, suitable for gears and bearings.

Composites

Composite materials such as carbon fiber-reinforced plastics can also be machined using CNC technology for lightweight and high-strength prototypes.

Applications of CNC Machining Prototyping

CNC machining prototyping is widely used across industries due to its versatility and precision:

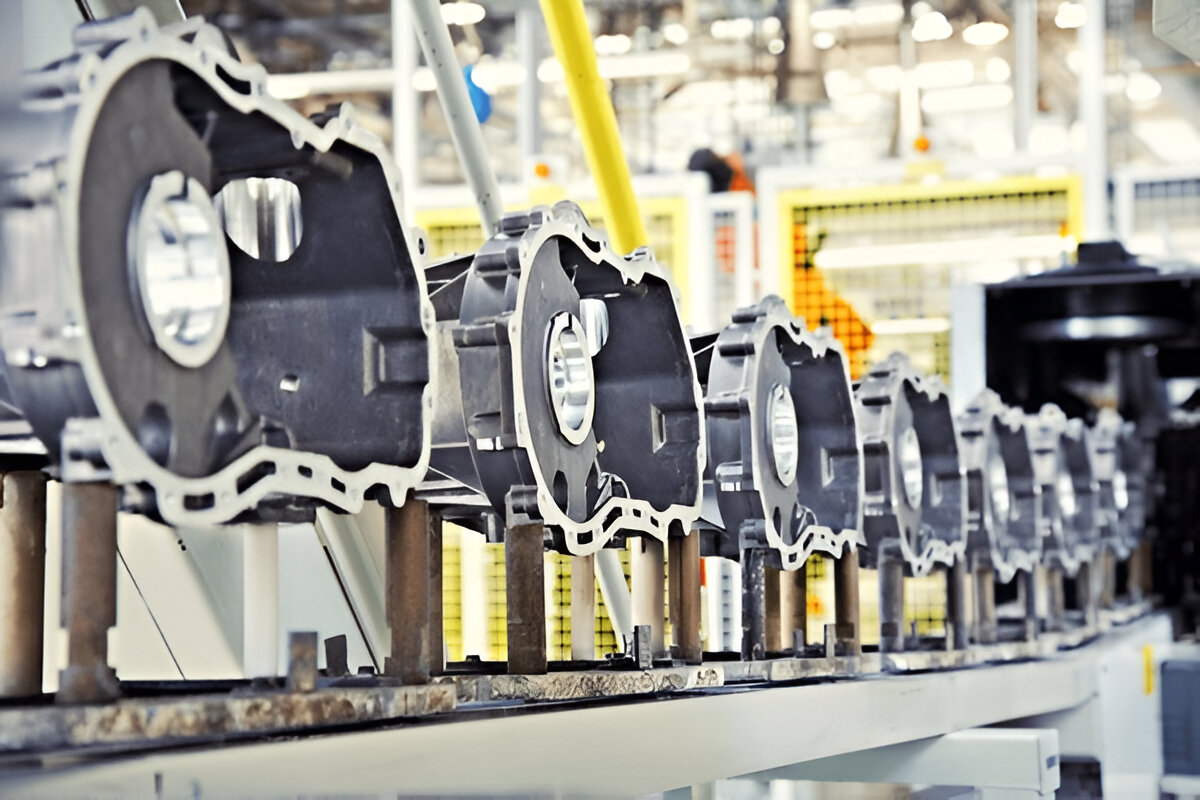

Automotive Industry

Developers use CNC prototypes for engine components, custom body parts, and interior fittings. Prototyping allows thorough testing for performance and safety before mass production.

Aerospace

CNC machining produces lightweight, durable prototypes for aircraft components and assemblies, where precision and material properties are critical.

Medical Devices

Custom implants, surgical tools, and diagnostic equipment are prototyped to meet strict regulatory and functional requirements.

Consumer Electronics

Manufacturers prototype casings, connectors, and intricate internal parts to ensure ergonomic design and optimal functionality.

Industrial Equipment

CNC prototypes help test gears, valves, and mechanical components under realistic conditions.

Architecture and Art

Custom sculptures, architectural models, and intricate designs can be rapidly prototyped with CNC machining, allowing artists and architects to bring their visions to life.

Difference Between CNC Prototyping and Other Prototyping Methods

While CNC machining is a powerful prototyping method, it is important to understand how it compares to other options:

3D Printing (Additive Manufacturing)

- Builds parts layer-by-layer, ideal for complex internal geometries.

- Usually slower for larger parts and limited in material choices.

- Often less durable and precise than CNC machined parts.

Injection Molding Prototypes

- Suitable for high-volume production with consistent quality.

- High tooling costs make it impractical for early-stage prototyping.

Manual Machining

- More labor-intensive and prone to human error.

- Less consistent precision compared to CNC machining.

CNC machining prototyping strikes a balance between speed, precision, and material choice, making it a preferred method for functional and near-production-ready prototypes.

How to Choose the Right Custom CNC Services Provider

Finding the right partner for custom CNC services is essential for successful prototyping. Here are some tips to help you make the best choice:

Assess Experience and Capabilities

Look for providers with expertise in your industry and the ability to work with your desired materials and tolerances.

Review Equipment and Technology

State-of-the-art CNC machines and software ensure higher precision and faster turnaround.

Evaluate Quality Control Processes

Ask about inspection methods, certifications (ISO, AS9100), and quality assurance procedures.

Communication and Support

Choose a provider who communicates clearly and can offer design feedback or prototyping advice.

Turnaround Time and Cost

Balance your budget with the provider’s ability to deliver prototypes on time without sacrificing quality.

Request Samples or References

Reviewing past work or speaking with previous clients can give insight into the provider’s reliability and quality.

Tips for Searching “CNC Manufacturing Near Me”

If you’re searching for cnc manufacturing near me, here are some practical tips to find the best local providers:

Use Location-Based Search Engines

Start with Google or Bing by entering your city or region along with keywords like “CNC machining prototyping” or “custom CNC services.”

Check Industry Directories

Platforms like ThomasNet, MFG.com, or local manufacturing associations often list verified CNC shops.

Read Reviews and Ratings

Look for customer feedback on Google Reviews, Yelp, or industry-specific forums to gauge reputation.

Visit Facilities if Possible

A site visit can help you verify equipment, meet the team, and discuss your project requirements.

Ask for Quotes and Compare

Request detailed quotes and timelines from multiple providers to find the best fit.

Future Trends in CNC Machining Prototyping

The field of CNC machining prototyping is continuously evolving, with exciting advancements on the horizon:

Automation and AI Integration

More CNC machines will incorporate AI for optimizing toolpaths, predictive maintenance, and adaptive machining, improving speed and precision.

Hybrid Manufacturing

Combining CNC machining with additive manufacturing allows for even greater design freedom and complexity.

Sustainable Materials and Processes

Growing emphasis on environmentally friendly materials and waste reduction techniques will shape CNC prototyping practices.

Cloud-Based Collaboration

Digital platforms will enable real-time collaboration between designers, engineers, and CNC providers worldwide.

Enhanced Multi-Axis Machining

Five-axis and even more complex machining centers will allow for intricate parts with fewer setups and higher accuracy.

Practical Considerations When Using CNC Machining Prototyping

While CNC machining prototyping offers tremendous advantages, it’s important to understand some practical considerations to maximize its benefits.

Design for Manufacturability

Designing parts with CNC machining in mind is crucial. Certain geometries may be challenging or expensive to machine—such as deep cavities or extremely thin walls. Early collaboration with your custom CNC services provider can help optimize your design for manufacturability, reducing costs and lead times.

Tolerances and Surface Finish

Understanding the required tolerances for your prototype helps avoid unnecessary machining precision that drives up cost. Similarly, surface finish requirements can influence the machining process; some finishes require additional post-processing like polishing or coating.

Prototype Iterations

Prototyping often involves multiple iterations to perfect the design. CNC machining is flexible enough to accommodate design changes quickly, but complex changes might require reprogramming CAM toolpaths, affecting turnaround time.

Material Selection and Cost

While CNC machining supports a wide range of materials, each comes with cost and machining time considerations. Metals tend to be more expensive and time-consuming to machine than plastics. For early-stage prototypes, using lower-cost materials that simulate the mechanical properties of the final material can be a smart choice.

Cost Factors in CNC Machining Prototyping

Cost is a major consideration for any prototyping project. Understanding what drives CNC machining costs can help you budget effectively.

Setup Costs

Initial setup includes programming the CNC machine, selecting tooling, and preparing the workpiece. Complex parts or small batch sizes may increase setup time, raising overall cost.

Material Costs

Material prices vary widely. High-performance metals like titanium are costly, while plastics such as ABS are more affordable. Material choice should balance performance needs with budget constraints.

Machine Time

The complexity and size of the part influence machining time. Intricate geometries or tight tolerances require slower feeds and multiple passes, increasing machine hours.

Finishing and Secondary Operations

Processes like anodizing, polishing, heat treating, or assembly add to costs but may be necessary for functional or aesthetic reasons.

Quantity

Prototyping is typically a low-volume process, so cost per unit is higher than mass production. However, CNC machining can scale from single prototypes to small batch runs efficiently.

Real-World Case Studies: CNC Machining Prototyping in Action

Case Study 1: Aerospace Component Development

An aerospace startup needed to prototype a lightweight bracket for a drone. Using CNC machining prototyping, they chose aerospace-grade aluminum for strength and weight savings. The rapid turnaround allowed the team to test several iterations quickly, optimizing the design for durability and aerodynamic performance. Ultimately, the prototype closely matched the production specifications, reducing the time from concept to flight-ready part.

Case Study 2: Medical Device Customization

A medical device manufacturer required a prototype of a surgical tool with complex internal channels for fluid flow. Using custom CNC services, they machined the prototype from biocompatible stainless steel. The precision of CNC machining ensured that the tool met stringent regulatory standards and functioned properly in simulated surgical tests, speeding approval and clinical trials.

Case Study 3: Consumer Electronics Housing

A startup developing a new smart home device needed an aesthetically pleasing and robust enclosure prototype. CNC machining prototyping was used with polycarbonate plastic, allowing the team to assess ergonomics, assembly, and heat dissipation. The prototype helped identify minor design flaws early, preventing costly mistakes during injection molding.

How to Maximize Your CNC Machining Prototyping Investment

Collaborate Early with Your CNC Provider

Engaging your custom CNC services partner during the design phase allows for early input on design-for-manufacturing (DFM) improvements, tool selection, and cost-saving measures.

Prototype in Phases

Start with basic functional prototypes to validate fit and assembly, then proceed to refined versions focusing on surface finish or aesthetics.

Use Simulation Tools

Leverage CAD/CAM software simulation to preview machining operations and catch potential issues before the physical prototype stage.

Consider Hybrid Prototyping

For complex parts, combining CNC machining with additive manufacturing or other processes can reduce costs and expand design options.

Finding Reliable CNC Manufacturing Near Me

When you search for cnc manufacturing near me, consider these steps for finding a reliable local partner:

- Check Certifications: Look for ISO 9001 or AS9100 certifications, indicating high quality and process controls.

- Ask for Prototypes: Request sample prototypes or case studies to evaluate machining quality.

- Verify Capabilities: Ensure the shop has the machinery (e.g., 3-axis, 5-axis CNC) and material expertise you need.

- Evaluate Customer Service: A responsive and knowledgeable provider can make a huge difference in your project’s success.

- Location and Logistics: Proximity can reduce shipping times and costs, plus enable easier communication and visits.

Local CNC manufacturers often offer faster turnaround times and personalized service, which are crucial for iterative prototyping.

The Role of Technology in Evolving CNC Machining Prototyping

Technological advancements are continuously reshaping CNC machining prototyping:

Digital Twin Technology

Creating a virtual twin of your CNC prototype process can help optimize machining parameters, predict tool wear, and improve part quality.

IoT Integration

Internet of Things (IoT) sensors on CNC machines monitor performance in real-time, enabling predictive maintenance and reducing downtime.

Cloud-Based CAM Solutions

Cloud platforms enable seamless collaboration between design teams and CNC shops, speeding up programming and revisions.

Advanced Tool Materials

The development of harder, longer-lasting cutting tools improves machining speed and surface finish, lowering costs.

Conclusion

CNC machining prototyping is a powerful and versatile process that plays a crucial role in modern product development. By enabling precise, functional prototypes from a wide variety of materials, it helps companies accelerate innovation, reduce costs, and improve final product quality.

Whether you are an engineer refining a complex mechanical part, a designer crafting a custom consumer product, or a manufacturer looking to scale production, understanding CNC machining prototyping is essential.

Remember to carefully evaluate your options and find the right custom CNC services provider near you by searching for “cnc manufacturing near me.” With the right partner and technology, your prototypes can seamlessly transition from concept to reality, paving the way for successful product launches.