Beyond the Blueprint: How Zeometrix's CNC Machining Brings Ideas to Life in Bangalore

Introduction

In today’s fast-paced industrial world, ideas alone aren’t enough—they need to be transformed into precise, functional products that deliver performance and value. This is where CNC machining plays a transformative role. CNC (Computer Numerical Control) technology enables the conversion of complex digital blueprints into high-precision parts, ensuring speed, accuracy, and repeatability.

As one of the leading CNC machining service providers in Bangalore, Zeometrix has been instrumental in helping businesses, startups, and innovators bring their designs to life. Whether it’s a prototype for a new product or a high-volume batch of components for the automotive and aerospace industries, Zeometrix provides cutting-edge machining solutions tailored to customer needs.

This blog explores how Zeometrix goes beyond the blueprint by bridging the gap between imagination and reality, supporting Bangalore’s thriving industrial ecosystem, and driving India’s manufacturing growth story.

CNC Machining: Turning Designs into Reality

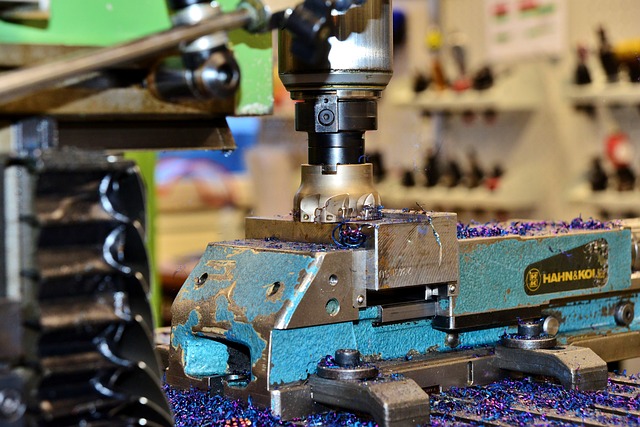

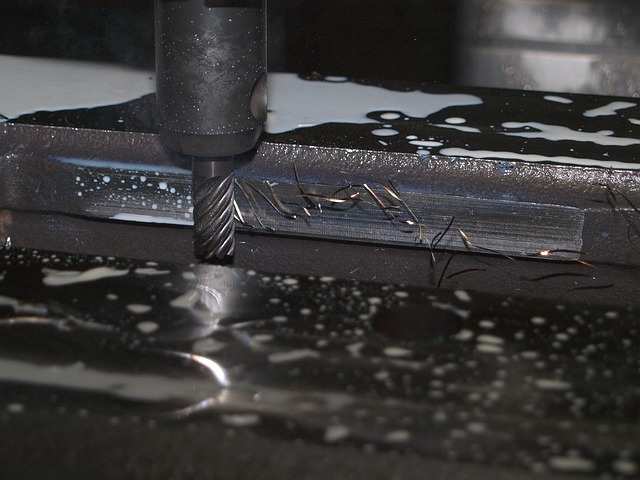

At its core, CNC machining is the process of using computer-controlled machines to shape raw materials—such as aluminum, steel, brass, and composites—into finished parts. Unlike traditional manual machining, CNC allows for automation, precision, and consistency, making it the backbone of modern manufacturing.

The journey typically follows these steps:

-

Blueprint Creation – Designers develop 2D or 3D models using CAD software.

-

Programming – CAM (Computer-Aided Manufacturing) software converts the design into machine-readable instructions.

-

Machining – CNC equipment executes the program, cutting, milling, drilling, or turning the material with extreme accuracy.

-

Finishing & Inspection – Final touches like polishing, coating, and quality checks ensure the part is production-ready.

At Zeometrix, this process is elevated through state-of-the-art machinery, skilled engineers, and a customer-focused approach, ensuring every idea is turned into a reality with unmatched precision.

Why Bangalore is the Epicenter of CNC Machining

Bangalore has emerged as a hub for aerospace, automotive, electronics, medical devices, and industrial equipment manufacturing. The city’s combination of technical talent, innovation-driven startups, and advanced industrial infrastructure makes it the perfect breeding ground for CNC machining.

Key factors that fuel CNC growth in Bangalore:

-

Strong ecosystem of R&D centers and OEMs.

-

Skilled engineers and machinists trained in the latest technologies.

-

Proximity to suppliers, raw materials, and export facilities.

-

Demand from sectors like EVs, aerospace, defense, and medical tech.

Zeometrix capitalizes on this ecosystem by delivering end-to-end CNC machining solutions for clients across industries.

Zeometrix: Beyond Conventional Machining

While many providers offer CNC machining, Zeometrix differentiates itself by going beyond the basics. It’s not just about cutting materials—it’s about bringing innovation to life.

Core Capabilities of Zeometrix CNC Machining

-

High-Precision CNC Milling & Turning

-

Multi-axis machining for complex geometries.

-

Micron-level accuracy for high-performance industries.

-

-

Rapid Prototyping

-

Quick turnaround for startups testing new designs.

-

Functional prototypes that are ready for real-world validation.

-

-

Batch Production

-

Flexible capacity for both low-volume and mass production.

-

Consistency across every manufactured unit.

-

-

Custom Component Fabrication

-

Tailored solutions for unique design requirements.

-

Collaboration with clients for design optimization.

-

-

Post-Machining Services

-

Surface finishing, heat treatment, and coating for durability.

-

Strict quality checks using CMM (Coordinate Measuring Machines).

-

By integrating design consultation, prototyping, and production under one roof, Zeometrix acts as a true partner in innovation.

How Zeometrix Brings Ideas to Life

1. From Concept to Prototype

For startups and innovators, moving from a sketch to a functional prototype can be daunting. Zeometrix simplifies this by offering rapid CNC prototyping, enabling clients to test designs quickly and affordably.

2. Optimizing for Manufacturability

Many designs face challenges during production. Zeometrix’s engineers collaborate with clients to provide Design for Manufacturability (DFM) feedback, ensuring products are not only functional but also cost-efficient to produce at scale.

3. Ensuring Repeatability and Quality

For industries like aerospace and medical, consistency is critical. Zeometrix’s automated CNC processes ensure every part produced matches specifications, batch after batch.

4. Bridging Small and Large-Scale Production

Whether a company needs 10 custom prototypes or 10,000 identical parts, Zeometrix provides scalable solutions, ensuring flexibility without compromising quality.

Industries Benefiting from Zeometrix CNC Machining

CNC machining is indispensable across industries, and Zeometrix supports a wide range of sectors:

-

Automotive & EVs: Engine components, gears, brackets, and housings.

-

Aerospace & Defense: Lightweight, high-strength precision parts.

-

Medical Devices: Surgical tools, implants, and housings with tight tolerances.

-

Electronics & Electricals: Enclosures, heat sinks, and connectors.

-

Industrial Machinery: Custom machine parts and replacement spares.

By serving these industries, Zeometrix ensures Bangalore remains at the forefront of industrial innovation.

The Technological Edge of Zeometrix

Zeometrix’s commitment to innovation is reflected in its state-of-the-art infrastructure:

-

5-axis CNC machining centers for complex geometries.

-

High-speed milling and turning machines for efficient production.

-

CAD/CAM integration for seamless design-to-manufacture workflows.

-

CMM inspection systems to validate precision and accuracy.

-

Robust ERP systems for project tracking and quality management.

This technological arsenal ensures Zeometrix can deliver products that meet both Indian and international standards.

Supporting the Make-in-India Initiative

Zeometrix’s CNC machining services align strongly with the Make-in-India movement:

-

Reducing imports by manufacturing precision components locally.

-

Strengthening supply chains by sourcing raw materials from Indian vendors.

-

Boosting exports by producing globally competitive CNC parts.

-

Upskilling talent through training in advanced machining techniques.

By doing so, Zeometrix not only supports local industries but also enhances India’s reputation as a world-class manufacturing hub.

Sustainability in CNC Machining

Manufacturing excellence today must also be environmentally conscious. Zeometrix integrates eco-friendly practices into its CNC operations:

-

Energy-efficient CNC machines to reduce power usage.

-

Recycling and reusing metal scrap.

-

Implementing lean manufacturing to minimize waste.

-

Eco-friendly surface treatments and coatings.

This focus on green manufacturing ensures that innovation doesn’t come at the cost of sustainability.

Challenges in CNC Machining and Zeometrix’s Response

The CNC industry faces challenges such as rising raw material costs, global competition, and the need for constant upskilling. Zeometrix addresses these with:

-

Process automation to reduce costs and improve efficiency.

-

Advanced training programs for machinists and engineers.

-

Continuous investment in the latest CNC technologies.

-

Collaborative client partnerships for innovation-driven solutions.

This proactive approach ensures Zeometrix remains resilient and future-ready.

The Future of CNC Machining with Zeometrix

As industries adopt Industry 4.0 practices and shift towards smart manufacturing, CNC machining will play an even bigger role. Zeometrix is preparing for this future by:

-

Integrating IoT-enabled smart CNC machines.

-

Expanding its capacity to cater to EVs, aerospace, and renewable energy sectors.

-

Enhancing digital twin capabilities for virtual prototyping.

-

Strengthening export partnerships for global expansion.

With these advancements, Zeometrix continues to be a trailblazer in precision manufacturing.

Conclusion

CNC machining is no longer just a manufacturing process it is the bridge between imagination and realization. At Zeometrix, this philosophy is deeply ingrained. By going beyond the blueprint, Zeometrix ensures that every idea whether from a startup innovator or a global OEM can be transformed into a tangible, high-quality product.

Through cutting-edge technology, skilled expertise, customer-centric values, and alignment with national initiatives like Make-in-India, Zeometrix continues to shape the future of manufacturing in Bangalore and beyond.

For businesses looking to turn ideas into reality, Zeometrix stands as a trusted partner that doesn’t just follow blueprints but brings them to life with precision, reliability, and innovation.