Why CNC Machining Services in Bangalore Are in High Demand

In recent years, Bangalore has emerged not only as the “Silicon Valley of India” in terms of software and IT, but also increasingly as a manufacturing and precision engineering hub. Among the manufacturing services, CNC machining Services in Bangalore is seeing especially strong demand. In this post, we’ll explore the factors driving that demand, what advantages CNC machining offers, key industries in Bangalore making use of it, challenges, and what to consider if you’re looking to engage CNC machining services in the city.

What is CNC Machining & Why It’s Important

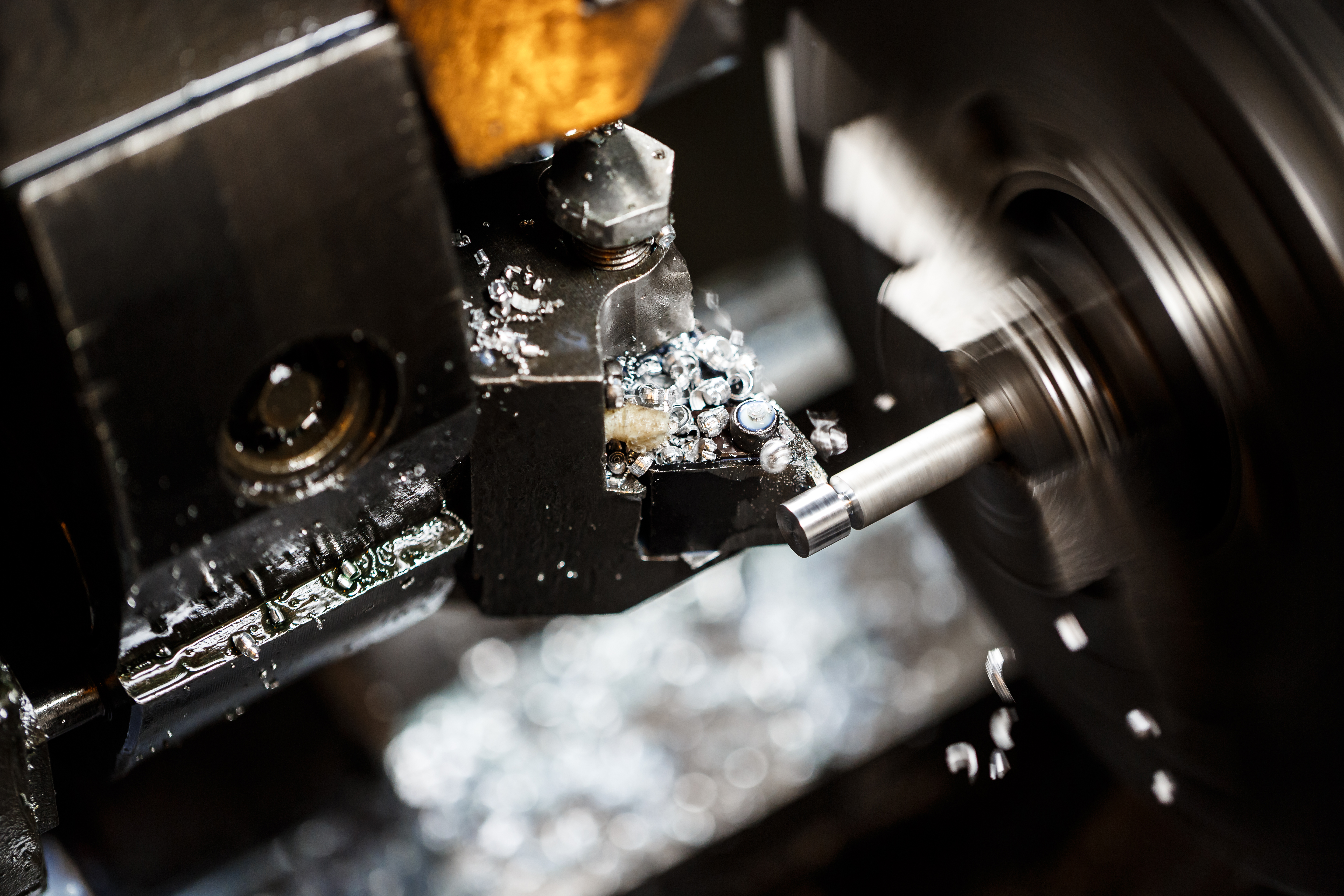

CNC stands for Computer Numerical Control. CNC machining refers to manufacturing processes where pre‑programmed computer software controls tools like mills, lathes, grinders, routers, etc., to remove material and produce parts with high precision. Compared to traditional manual machining, CNC machining allows:

- Much tighter tolerances and consistency from part to part.

- Faster prototyping and iteration, reducing the time from design to physical part.

- Reduced waste, since paths are optimized, cuts are precise, and operations can be automated.

- Efficiency, repeatability, and capability to produce both low‑volume custom jobs and larger series, depending on setup.

All these features make CNC machining a backbone for precision manufacturing in many modern sectors.

Why Bangalore Specifically?

So what is it about Bangalore that makes CNC machining services especially in high demand there?

1. Strong Talent Pool & Engineering Education

Bangalore has a rich ecosystem of technical institutes, engineering colleges, and vocational training centers. This means there's a steady supply of engineers, machinists, CAD/CAM programmers, and operators who are familiar with modern machining and software tools.

Because CNC machining requires both programming/design skills (CAD/CAM) and good shop‑floor skills (setting up machines, maintaining precision, monitoring operations), having this mix of talent locally is a major advantage.

2. Industrial Ecosystem & Demand Drivers

Several industries in and around Bangalore are hungry for high-precision components:

- Electronics / IoT / Consumer Devices: Enclosures, connectors, heat sinks, components with tight tolerances.

- Automobile & Auto Components: Bangalore is home to many OEMs and suppliers; components like shafts, housings, transmission parts often manufactured via CNC.

- Aerospace & Defence: Some companies demand very high precision, complex geometries, and stringent quality standards.

- Medical Devices / Biotechnology: Surgical tools, diagnostic equipment parts, etc., need both precision and regulatory compliance.

This varied demand encourages investment in better machines, more capability, and pushes CNC service providers to upgrade their infrastructure and capacity.

3. Up‑to‑Date Technology & Smart Manufacturing

Many CNC shops in Bangalore are adopting more modern technologies:

- Advanced multi‑axis CNC machines (3‑axis, 4‑axis, 5‑axis)

- Better CAD/CAM software, simulation tools, design for manufacturability (DFM) practices.

- Adoption of smart manufacturing practices: IoT for machine health, digital inspection, process monitoring, predictive maintenance. These add to reliability and reduce downtime.

4. Competitive Costs & Economies of Scale

While setting up a CNC machining facility requires investment, the operational costs in Bangalore are often lower compared to many global locations (especially for labor, space, utilities) in relative terms. Also, because there is existing competition and many smaller to medium‑sized manufacturers, there is pressure to remain cost‑competitive. This spurs efficiencies, better scheduling, better utilization of machines, and optimizing of raw material usage. All of this helps reduce per‑part cost.

Also, for many firms, especially in hardware, prototypes or small to medium volume production are common needs. Traditional tooling, molding, or manual machining may get expensive or slow. CNC fits into that space well—good flexibility, lower tooling cost, quicker turnaround.

5. Infrastructure, Clusters & Supply Chains

Bangalore has industrial clusters (e.g. Peenya, Bommasandra etc.), good logistics (roads, connectivity), suppliers of raw materials, nearby vendors for finishing, coatings, calibration, etc. This means a CNC shop in Bangalore can offer more integrated services, faster supply, lower shipping or transit delays. Also possibility of closer collaboration with clients (design, prototyping, testing) because physical proximity makes communication and iteration easier.

6. Globalization & Export Demand

Some CNC‑machined parts are demanded not just locally but globally: for export, for international OEMs, etc. As India is increasingly being considered for precision engineering exports, there’s pressure/scope for Bangalore‑based firms to adhere to global standards, invest in certification, quality control, and deliver at competitive costs and timelines. That increases overall demand and drives growth in capability.

Advantages of CNC Machining Over Traditional Methods — Why Demand is High

To fully understand why CNC machining services in Bangalore are so much in demand, let’s compare with more traditional/manual methods, showing what CNC brings.

| Feature | CNC Machining | Traditional / Manual Machining |

| Precision & Tolerances | High repeatability, very tight tolerances (often in microns) | More variation, depends heavily on operator skill |

| Speed & Turnaround | Faster setup, faster switching of jobs, ability to run continuously and produce prototypes quickly | Slower, more manual effort, perhaps longer lead times |

| Flexibility for small‑to‑medium batches / prototyping | Very good — you can reprogram, make changes, test prototypes without large additional tooling cost | Less flexible, changes often costly in time or tooling |

| Waste / Material Efficiency | Better path optimization, less scrap, more efficient material use | Often more waste; more manual cutting or roughing; inefficiency in tool paths and setups |

| Labor Dependence | Lower dependency on manual labor; more programming & supervision roles; fewer needs for artisan‑level skills for some task. | Heavier reliance on skilled machinists; variability in output tied to labor quality |

| labor; more programming & supervision roles; fewer needs for artisan‑level skills for some task. | variability in output tied to labor quality | |

| Cost per Part (especially for smaller runs / complex parts) | Typically lower or more predictable for small / intricate jobs; user can amortize programming & setup costs well | For simple, high volume or very basic parts, sometimes manual/traditional can be acceptable; but as complexity rises or tolerances tighten, manual becomes inefficient |

Challenges / Considerations

Even though demand is high, there are several challenges or limitations that CNC machining service providers and clients must navigate. Recognizing these will help ensure smoother outcomes.

- High Capital Expenditure & Maintenance

CNC machines cost money — for machinery itself, for tooling, for software licenses, and for upkeep (maintenance, calibration). Downtime or breakdowns can be costly. - Skilled Programming & Setup

You need good CAD/CAM programmers, good operators, good quality control staff. A poorly programmed CNC job or poorly set up machine can lead to scrap, defects, or over‑run cost. - Lead Times for Complex Jobs

If parts are complex, or require special materials, finishing, or inspection, lead times can still be substantial. Also coordination of multiple vendors (e.g. for finishing, coatings) adds time. - Quality & Certification Standards

For industries like aerospace, medical devices, there are strict regulatory and quality standards. CNC shops need to invest in certifications, inspection equipment, process documentation, traceability etc., which raises cost and complexity. - Material Choices and Sourcing

For certain high‑grade materials (exotic alloys, specialty metals), sourcing cost or supply chain issues can be a hurdle. - Competition Pressure

Because many CNC service providers exist (especially smaller shops trying to capture local demand), competition can drive prices down, sometimes in ways that risk compromising on quality. Clients must be careful in vendor selection and validation.

What Clients Should Look for When Seeking CNC Machining Services in Bangalore

If you are a designer, start‑up, OEM, or anyone needing CNC machining, here are things to evaluate to get the most value and avoid bad surprises:

- Clarity of Specifications: Provide detailed CAD files, tolerances, surface finish requirements, material specification. The more precise you are, the fewer surprises later.

- Experience & Past Projects: Ask for portfolios, similar parts made, references. Are they able to handle your volume, your complexity?

- Machine Capability: What types of machines do they have (axis count, size, material handling)? Do they have 3‑axis / 4‑axis / 5‑axis? Capacity to do both small batch and larger runs?

- Quality Assurance / Inspection Infrastructure: Do they have measurement / metrology tools (CMM, optical, etc.), process audits, standard operating procedures, traceability?

- Technology & Software Proficiency: CAD/CAM tools, simulation tools, ability to optimize toolpaths, minimize material waste, foresee machining issues.

- Turnaround Time & Communication: How fast can they deliver prototypes, small batches, larger orders? What's their lead time? Do they offer updates or allow collaboration during the process?

- Cost Transparency: Ensure quotes show breakdown (material cost, setup, machining time, finishing, shipping). This helps compare vendors fairly.

- After‑sales Support / Warranty / Rework Policy: Mistakes happen. A reliable vendor will take responsibility for defects, rework parts if needed, stand by quality.

The Future: Where This Demand Is Headed

Given how rapidly industries are evolving, and with several global and local trends, the demand for CNC machining in Bangalore is likely to grow further. Some elements of the future include:

- More automation / smart factories: More integration of IoT, real‑time monitoring, predictive maintenance. This will increase throughput and reliability.

- Increased use of advanced materials: Composites, titanium, aerospace alloys, high‑temp alloys. As clients push for lighter and more efficient parts, the need for handling difficult‑to‑machine materials will rise.

- Miniaturization and precision: In electronics, medical devices, instrumentation — as components get smaller and more precise, CNC shops with ability to machine to tight tolerances will be in more demand.

- Rapid prototyping / additive + subtractive hybrid manufacturing: Some shops may combine CNC machining with 3D printing / additive manufacturing to produce complex shapes, then finish via CNC for strength or surface quality.

- Global export competitiveness: With India pushing “Make in India”, incentives, and global supply chain shifts, Bangalore’s CNC firms may play larger roles in supplying to international OEMs, provided they meet quality, delivery, and compliance standards.

Conclusion

In summary, CNC machining services in Bangalore are in high demand because of a confluence of favorable factors: the availability of skilled workforce, strong industrial demand across sectors like electronics, automotive, aerospace and medical; competitive cost environment; modern machinery and adoption of smart practices; and good infrastructure/supply chain support.