CNC Machining in Bangalore Driving Automotive Innovation

The global automotive industry is transforming faster than ever. From electric mobility to autonomous driving, and from lightweighting to hyper-customization, the demands on vehicle design and production are escalating. At the heart of this transformation lies CNC (Computer Numerical Control) machining, a precision manufacturing technology that ensures parts are produced with unmatched accuracy, repeatability, and efficiency.

In India, and particularly in Bangalore, CNC machining has become the backbone of automotive innovation. The city—already known as the Silicon Valley of India—has extended its technological reputation into advanced manufacturing, making it a hub where automotive OEMs and Tier-1 suppliers source high-quality machined components. This article explores how CNC machining in Bangalore is driving the automotive revolution in 2025 and beyond.

Why CNC Machining Matters in Automotive Innovation

Automobiles today are more than just vehicles—they are computers on wheels, powered by intricate mechanical and electronic systems. Each system demands components that are:

- Dimensionally precise – within microns, ensuring proper fit and function.

- Durable – to withstand high loads, vibration, and temperature extremes.

- Repeatable – every part must meet the same standard across thousands of units.

- Lightweight yet strong – contributing to fuel efficiency and electric vehicle range.

CNC machining delivers these exact capabilities. By converting digital 3D designs into machine-readable code, CNC lathes, mills, grinders, and multi-axis machining centers manufacture components with tight tolerances, surface finishes, and geometric accuracy essential for automotive innovation.

Bangalore’s Role in the CNC Machining Ecosystem

Over the past decade, Bangalore has quietly evolved into a precision manufacturing capital, complementing its reputation for IT and startups. Factors behind this rise include:

- Proximity to OEMs and Tier-1 Suppliers

- Automotive clusters in Hosur, Tumkur, and Chennai are within logistical reach.

- Global OEMs like Toyota, Volvo, Mercedes-Benz, and Bosch operate in or around Bangalore.

- Strong Supplier Base

- Hundreds of CNC machining shops cater to automotive, aerospace, and industrial sectors.

- Facilities range from job shops to large-scale, ISO-certified machining plants.

- Skilled Workforce

- Engineering talent from Bangalore’s top institutes blends software expertise with manufacturing know-how.

- CNC operators, tool designers, and quality engineers are readily available.

- Technology Adoption

- 5-axis machining, live tooling, robotic automation, and digital twin simulations are increasingly common.

- Shops invest in CMMs, SPC systems, and ERP-driven workflows for consistent quality.

This ecosystem enables Bangalore’s manufacturers to support both domestic automotive production and global export supply chains.

Automotive Components Produced by CNC Machining in Bangalore

CNC machining supports a wide array of automotive parts, spanning powertrain, chassis, safety, and EV systems. Some examples include:

- Engine and Powertrain

- Cylinder heads, engine blocks (prototypes), and manifolds.

- Crankshafts, camshafts, pistons, and connecting rods.

- Gearbox housings, shafts, and gears with micron-level tolerances.

- Suspension & Steering

- Control arms, knuckles, and steering racks.

- Bush housings, brackets, and linkages.

- Braking Systems

- Brake calipers, rotors, and ABS housings.

- Precision bores for hydraulic systems.

- EV & Hybrid Components

- Battery enclosures and cooling plates (machined from aluminum).

- Motor housings, shafts, and reduction gears.

- Precision busbars and connectors for high-voltage systems.

- Safety-Critical Parts

- Airbag inflator housings.

- Seat belt system components.

- Sensor mounts and brackets.

Key CNC Capabilities Found in Bangalore Shops

The automotive-grade CNC machining facilities in Bangalore are equipped with:

- Multi-axis CNC mills & lathes (3-, 4-, 5-axis).

- Swiss-type lathes for small, complex parts like fuel injector nozzles.

- CNC grinding machines for high-precision finishing.

- CMMs and optical measurement systems for validation.

- Heat treatment & surface finishing integration (carburizing, nitriding, anodizing, plating).

- CAD/CAM integration for toolpath optimization and design-to-manufacture workflows.

This makes Bangalore competitive not just in cost, but in capability maturity for global automotive programs.

Driving Innovation Through CNC Machining

1. Lightweighting and Material Innovation

- CNC machining in Bangalore supports aluminum alloys, magnesium, titanium, and composites.

- Enables lighter chassis and engine parts that improve efficiency and EV range.

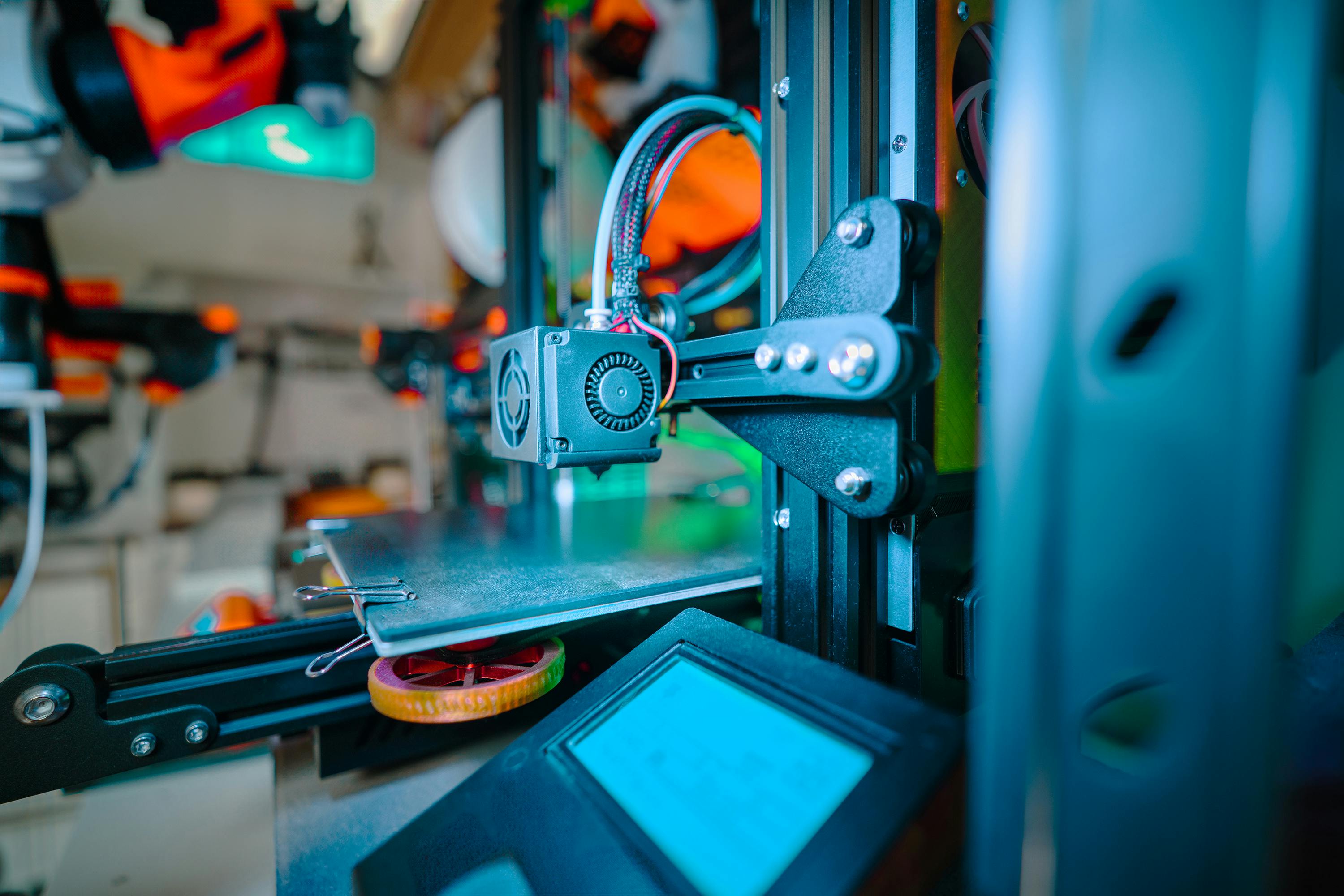

2. Rapid Prototyping and Faster Development

- OEMs can iterate designs quickly with CNC prototypes.

- Design validation is faster, reducing time-to-market for new models.

3. EV & Hybrid Vehicle Adoption

- Machining shops are adapting to produce battery trays, cooling plates, and e-motor housings.

- Precision ensures better thermal management, safety, and durability.

4. Integration of Automation

- Robotic part loading/unloading and in-cycle probing increase throughput.

- Shops achieve higher consistency and reduced cycle times.

5. Data-Driven Manufacturing

- Smart machining centers track spindle utilization, tool wear, and quality metrics.

- This digitalization ensures leaner, more predictable supply chains.

Comparison Framework: Choosing CNC Machining Vendors in Bangalore

-min.jpg)

When selecting a machining partner in Bangalore, automotive firms weigh several criteria:

- Certifications – ISO 9001, IATF 16949, AS9100 (for crossover aerospace-auto vendors).

- Tolerances – Ability to achieve ±5–10 microns for critical components.

- Batch Sizes – Flexibility for prototyping, pilot builds, and mass production.

- Material Expertise – Machining capability across steels, aluminum, alloys, composites.

- Technology – 5-axis, high-speed spindles, multi-tasking centers.

- Quality Assurance – CMM inspection, PPAP documentation, SPC controls.

- Lead Times – Prototyping in days; production scaling within weeks.

- Cost Transparency – Detailed quoting with cycle time, setup, and finishing breakdowns.

Case Study Example (Illustrative)

An electric vehicle startup in Bangalore needed lightweight motor housings machined from aluminum. By partnering with a local CNC shop equipped with 5-axis machines:

- Cycle time was reduced by 20% through optimized toolpaths.

- Scrap rates dropped below 1% due to in-process probing.

- Lead time for prototypes was cut from 3 weeks to 7 days.

- The shop scaled seamlessly from 20 prototypes to 2,000 units/month as the startup ramped production.

This case highlights Bangalore’s unique advantage: speed + scalability + cost-effectiveness.

Trends in CNC Machining for Automotive (2025)

- AI-Driven Toolpath Optimization: CAM software powered by AI reduces cycle time and tool wear.

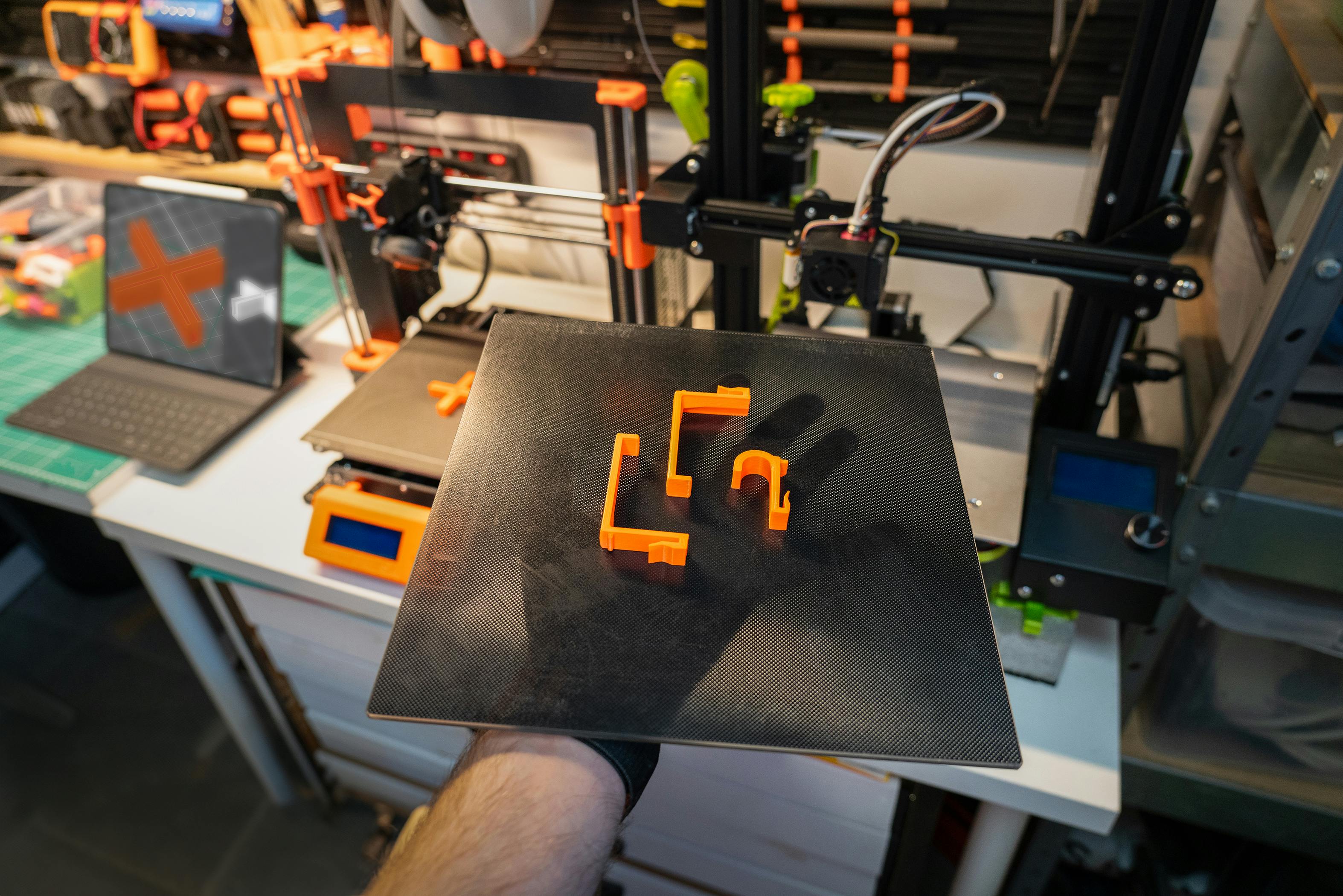

- Additive + Subtractive Hybrid: Combining 3D printing and CNC machining for complex EV components.

- Sustainability in Machining: Coolant recycling, energy-efficient spindles, and waste management are becoming key differentiators.

- Global Integration: Bangalore suppliers are integrating into global automotive supply chains with digital quality systems and export readiness.

Challenges & Solutions

- Challenge: Rising cost of raw materials (aluminum, alloys).

Solution: Smart nesting, scrap recovery, and supplier partnerships. - Challenge: Skilled labor shortage.

Solution: Operator training programs, semi-automation, AR-assisted machining. - Challenge: Maintaining quality at scale.

Solution: MES integration, automated inspection, and digital twins.

Future Outlook: Bangalore at the Center of Automotive Transformation

The automotive industry in India is forecasted to reach USD 300 billion by 2030. Bangalore is positioned to lead this growth, not just in software and R&D, but in precision manufacturing. With its blend of skilled talent, advanced machining facilities, and proximity to major OEMs, the city is set to become a global hub for CNC-driven automotive innovation.

Whether it’s enabling lighter EVs, producing high-performance engine components, or supporting autonomous vehicle hardware, CNC machining in Bangalore is no longer a supporting function—it is a strategic enabler of automotive progress.

Final Takeaway

For automotive companies—whether startups or global OEMs—Bangalore’s CNC machining ecosystem offers:

- Prototyping agility for design validation.

- Precision and repeatability for safety-critical components.

- Cost-effective scalability for high-volume production.

- Innovation support for EVs, lightweighting, and digital transformation.

By leveraging CNC machining in Bangalore, the automotive sector is not just keeping pace with global innovation—it is actively shaping the future of mobility.