Leading CNC Machine Manufacturers in Bangalore for Advanced Manufacturing

Over a decades, the city has also become a major force in manufacturing, particularly in precision engineering and CNC (Computer Numerical Control) machine manufacturing. As the world moves toward advanced manufacturing paradigms involving automation, Industry 4.0, IoT, and robotics, the CNC machine manufacturers in Bangalore are stepping up—providing machines and solutions that meet stringent global standards, serving industries from aerospace and automotive to medical devices and electronics.Bangalore, often called the Silicon Valley of India, has long been known for its IT prowess. But over recent decades, the city has also become a major force in manufacturing, particularly in precision engineering and CNC (Computer Numerical Control) machine manufacturing. As the world moves toward advanced manufacturing paradigms involving automation, Industry 4.0, IoT, and robotics, the CNC machine manufacturers in Bangalore are stepping up—providing machines and solutions that meet stringent global standards, serving industries from aerospace and automotive to medical devices and electronics.

In this post, we’ll explore:

- Why Bangalore is a strong base for CNC machine manufacturing

- Key players (manufacturers) in Bangalore and what they offer

- What features and innovations are shaping the CNC machine market here

- Challenges and outlook

1. Why Bangalore Is a Strong Base for CNC Machine Manufacturing

Several factors combine to make Bangalore a favorable location for CNC machine tool manufacturing and advanced precision machining. These include:

- Skilled Workforce & Educational Ecosystem

Bangalore hosts premier engineering institutions (IISc, various engineering colleges, polytechnics) that produce trained mechanical engineers, CNC programmers, toolmakers, and machine tool designers. This means manufacturers can draw on local talent for design, R&D, and production. - Established Industrial Clusters & Infrastructure

Areas like Peenya Industrial Area, Bommasandra, and parts of outskirts have a well‑developed infrastructure, good supply chains (raw materials, precision components, toolings), logistics networks, and access to both domestic and international markets. - Adoption of Technology & Innovation

Manufacturers in Bangalore increasingly embed modern technologies — CAD/CAM systems, multi‑axis machining, automation, IoT sensors, robotics, real‑time monitoring — into their product development and manufacturing processes. Cost‑Competitiveness + Quality

Compared to many countries in Europe or North America, manufacturing overheads can be lower in Bangalore, while many companies maintain high quality through standards, certifications, and strong QA/QC processes. This makes CNC machines made here attractive both domestically and for export - Diverse Industry Demand

Demand comes from aerospace & defence (companies like HAL, DRDO, ISRO), automotive & EV industries, medical devices, electronics/semiconductors, and industrial equipment. This diversified demand pushes manufacturers to be versatile and precise.

2. Key Players in CNC Machine Manufacturing in Bangalore

Here are some of the leading companies based in or operating out of Bangalore that are major contributors to the CNC machine / precision manufacturing ecosystem. Their strength varies: some are large, established firms; others are more nimble or specialized.

|

Manufacturer |

Highlighted Products / Strengths |

What Makes Them Stand Out |

|

ACE Micromatic Group |

A broad range of CNC machines: turning machines, multitasking turning‑mills, etc. |

Strong R&D, large manufacturing scale, good after‑sales service; known for durable, high‑quality tool machines. |

|

Bharat Fritz Werner Ltd (BFW) |

Horizontal & vertical machining centers, turning centres, multi‑axis machines. |

One of the older, well‑established firms; deep experience; often a go‑to for critical machines. |

|

Jyoti CNC Automation Ltd |

Turning centres, vertical machining centres, horizontal machining centres; special purpose machines. |

Robust design, good customization; serves many industries. |

|

HMT Machine Tools Ltd |

CNC systems, lathes, various machine tools; strong government linkage historically. |

Trusted name; good reputation; often used in sectors needing high reliability. |

|

Lakshmi Machine Works (LMW) |

CNC turning centres, multi‑tasking machines, high precision. |

Known for engineering robustness; good for high volume as well as precision. |

|

AMS (Ace Manufacturing Systems / AMS Engineering) |

Milling machines, CNC lathes, drill‑tap centres, etc |

Flexible and attuned to customer needs; balancing cost and performance. |

|

SKS Automation |

Broad portfolio: milling, fibre laser cutting, bending machines etc. |

They offer not only manufacturing but also trading/importing machines, often giving selections of newer technologies. |

|

Patson Machines Private Limited |

Quality CNC machines with emphasis on endurance, uptime, low maintenance. |

Good for customers wanting reliability over flashy features. |

|

Control Technics, Hexa, Maura Technologies, Reya Technologies, Toolcraft Systems |

Various specialized CNC machines including routers, engraving, possibly more niche or smaller capacity machines. |

These companies often serve niche segments or offer more customizable / smaller‑batch solutions. |

3. Features, Trends, & Innovations Shaping the CNC Machine Market in Bangalore

What are the trends and features that customers (domestic and export) look for, and how are manufacturers responding? Here are some of the major ones:

a) Multi‑Axis Machining & Complex Geometries

Many high‑end applications (aerospace, medical, mould & die, automotive) demand complex shapes and surfaces. 4‑axis, 5‑axis, and multi‑tasking (turn‑mill, etc.) machines are in rising demand. Bangalore manufacturers are investing in these to remain competitive.

b) Automation, IoT & Smart Manufacturing

Integrating sensors to monitor machine health, tool wear, vibrations; predictive maintenance; remote monitoring of operations or dashboarding; automation of loading/unloading; robotic adjuncts or collaborative robotics (cobots) are being introduced. These reduce non‑productive time, improve quality consistency, and lower operating costs.

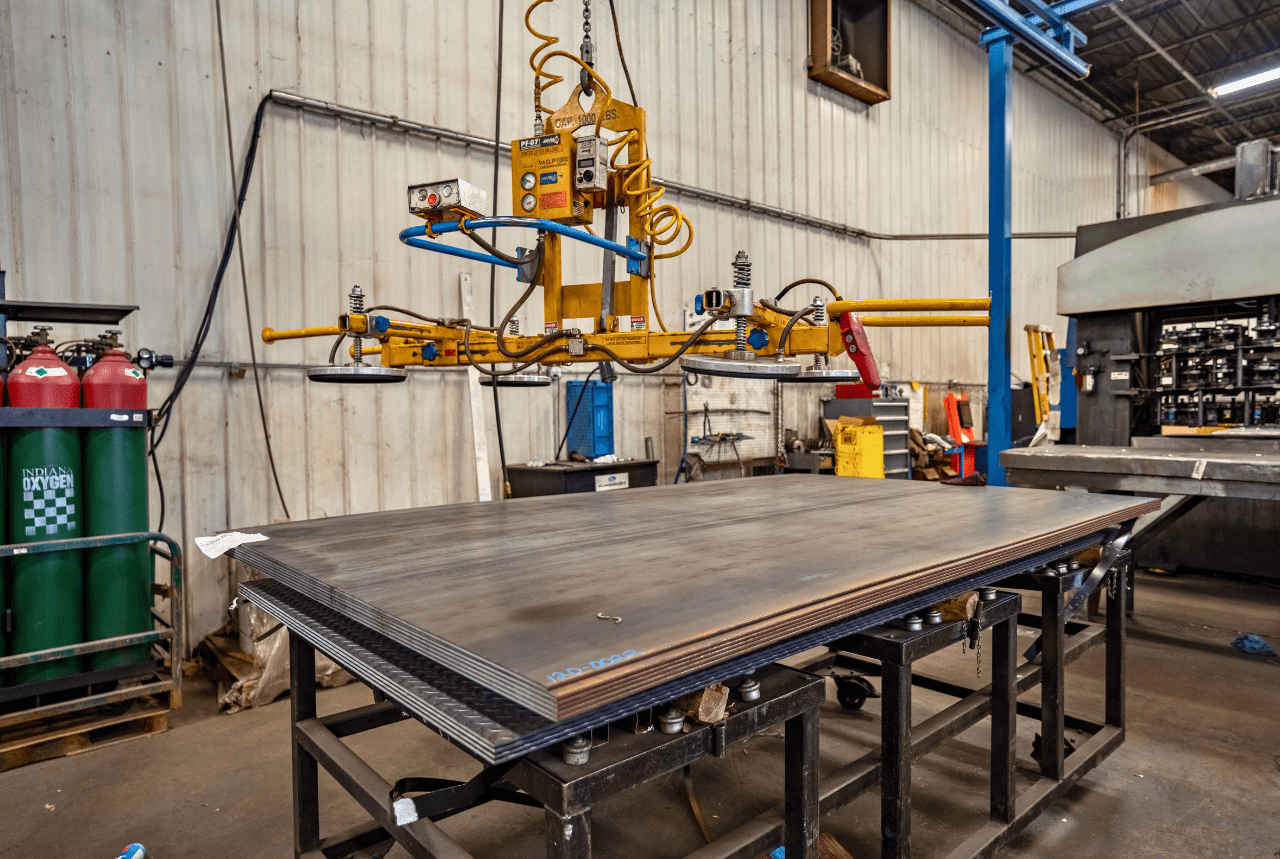

c) Higher Precision & Tight Tolerances

Especially for aerospace/defence, medical implants, semiconductor equipment, tolerances are very tight. Bangalore’s CNC machines are increasingly meeting these through better spindles, more accurate tool paths, higher rigidity, thermal stability. Also, better QC tools, coordinate measuring machines (CMM), quality inspection are part of the package.

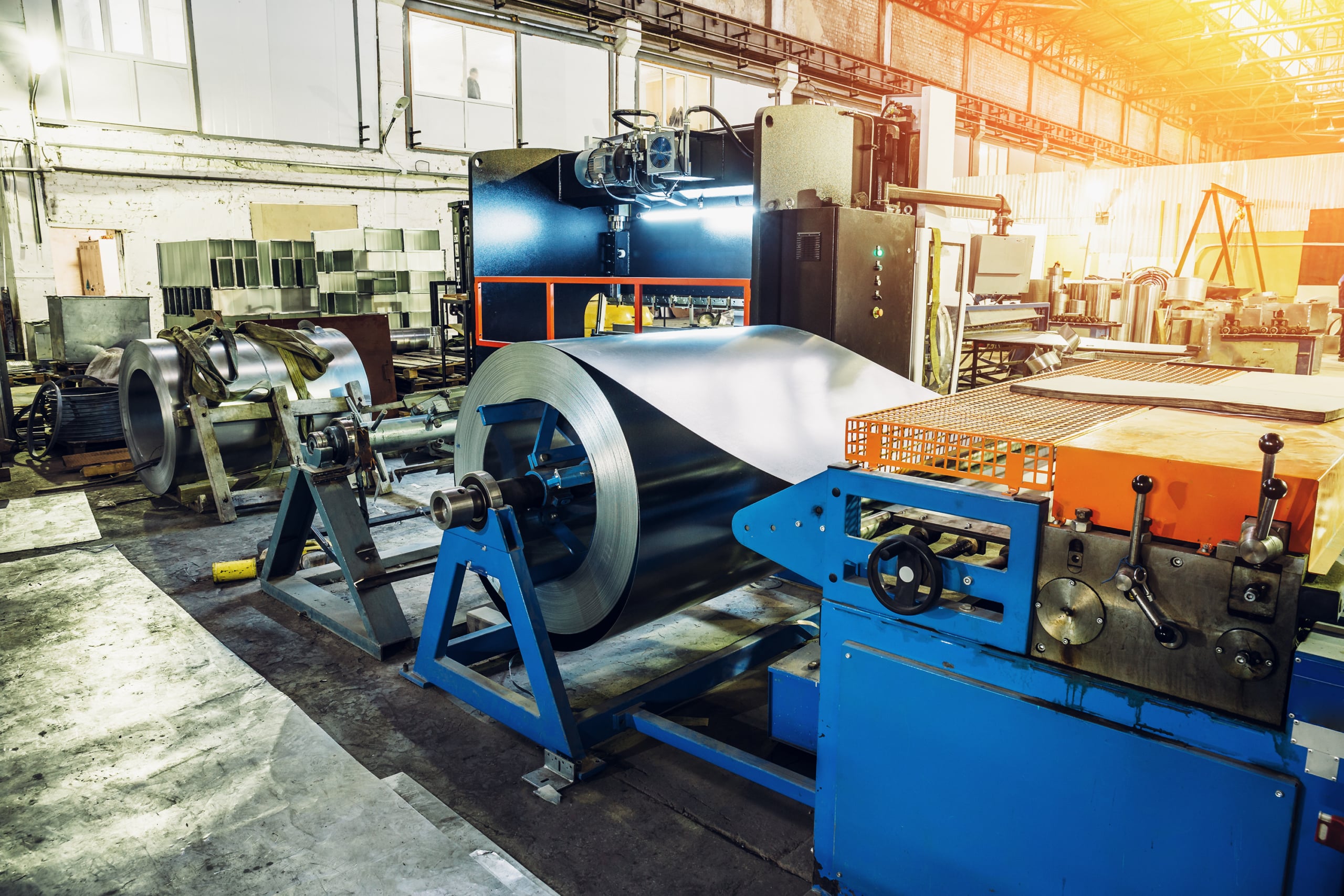

d) Material Versatility

Machines that can handle a range of materials: steels (hardened or alloyed), aluminium, titanium, stainless steels, composites, plastics. This matters as industries expand in material choices for strength, lightweighting, corrosion resistance. Manufacturers are building machines capable of higher power spindles, different cooling, chip removal, etc.

e) Customization & Special Purpose Machines (SPMs)

Not all applications are generic. Many customers need custom machines or special purpose machines (SPMs) designed for specific tasks: a special fixture, multi‑head setups, integrating robotics, etc. Some manufacturers in Bangalore specialize or at least offer these custom SPMs.

f) After‑Sales Support, Service, & Lifecycle Management

Because CNC machines are capital investments, customers care about support: spare parts, calibration, servicing, training, tool calibration, software updates. Manufacturers that offer strong support and quick turnaround for maintenance tend to gain loyalty. Bangalore manufacturers are increasingly building in such services.

g) Export & Standards Compliance

Many of the leading CNC machine manufacturers aim to serve not just India but international markets. To do so, they comply with international standards (ISO, CE marking, etc.), ensure material certifications, documentation, traceability, etc. Also, ability to deliver in a global supply chain is valued.

4. Challenges and Outlook

While the scenario is generally positive, there are challenges, and it’s useful to consider what the near future might hold.

Challenges

- High Capital Cost & Lead Times

Building or upgrading CNC machine manufacturing lines with modern tools, automation, multi‑axis capabilities requires large capital. Lead times for some components (spindles, drives, controllers) can be long especially if sourced internationally. - Technology Upgradation

Rapid technological change means continuous investment in R&D. If a manufacturer delays adopting newer control systems, sensor technologies, etc., they risk falling behind. - Skilled Manpower Gaps

Although Bangalore has educational institutions, the skills required for advanced CNC machine design, thermal dynamics, control engineering, software engineering for CAD/CAM and IoT, etc., are advanced. Upskilling or hiring such talent can be a bottleneck. - Competition from Imports / Global Players

Cheaper imported machines, particularly from East Asia, sometimes with lower costs or aggressive pricing, can pose competition. Buyers may also prefer imported brand names for perceived reliability or support. - Quality Assurance & Consistency

Ensuring tight tolerances, conformity, and repeatability consistently over many machines and lots is nontrivial. Maintaining QC, calibration, metrology, etc., adds cost. - Regulatory / Trade Barriers for Exports

Certifications, export regulations, supply chain constraints, foreign exchange volatility, tariffs—all can impact cost competitiveness for export.

Outlook & Opportunities

- Growth in EV, Aerospace, Defense, Medical Devices

Government impetus and demand in these sectors is increasing. Electric vehicles, unmanned aerial vehicles, satellites, medical implants—these all need high precision, advanced CNC machines. This opens up bigger domestic and export markets. Zeometrix - Smart Manufacturing / Industry 4.0 Adoption

As more manufacturers (even end‑users) demand machines with connectivity, predictive maintenance, AI‑based optimization, etc., CNC manufacturers who embed these or provide modular upgrades will have an edge. - Localising more Components

To reduce dependency on imports (controllers, spindles, precision ballscrews, etc.), there is opportunity for local component manufacturing. This can reduce costs, lead times, increase resilience. - Customization & Niche Applications

Opportunities exist in specialized applications: medical implants, biotech equipment, robotics, defense systems, scientific instrumentation. Such applications often need unique machine configurations, enabling manufacturers that are flexible to capture such markets. - Export Potential

As global supply chains look for diversified sourcing beyond China, India (and specifically manufacturing hubs like Bangalore) can capture export orders if quality, delivery, support, and certifications are in place.

5. Case Study / Example (Hypothetical / Real Highlights)

To illustrate how some manufacturers in Bangalore are distinguishing themselves:

- A company that traditionally made horizontal turning centres upgrades its machine line to include 5‑axis machining centres and adds IoT sensors to monitor tool wear; doing so increases throughput and reduces rejects in high‑precision aerospace parts.

- Another manufacturer partners with a robotics company to build automated loading/unloading stations (cobots) for their CNC machines, reducing operator fatigue, improving safety, and improving cycle times.

- In response to demand for medical implants, a firm introduces machines with improved thermal control and finishing capability, to meet both tight tolerances and biocompatibility surface finish requirements.

6. Best Practices for Choosing a CNC Machine Manufacturer in Bangalore

If you are a business considering buying CNC machines or partnering with manufacturers here, consider the following criteria:

- Technology & Machine Specifications

– Number of axes, spindle speed, power, rigidity, cooling, etc.

– Material capability.

– Precision, repeatability, etc. - Support & After‑sales Services

– Spare parts availability

– Service network

– Training and technical assistance - Customization and Flexibility

– Can the manufacturer offer SPMs or custom fixtures or adapt machines as per your product/industry? - Quality Certifications & Track Record

– Past clients, sectors served (especially critical sectors)

– ISO / CE / other standards - Cost of Ownership

– Not just purchase cost, but operating cost, maintenance, energy consumption, tool wear, etc. - Delivery Timelines & Reliability

– Lead time, ability to meet deadlines. - Upgradability

– Ability to integrate automation, later add more tooling, upgrade software, integrate connectivity.

Conclusion

Bangalore is fast emerging as a powerhouse for CNC machine manufacturing in India, combining its skill base, infrastructure, and growing demand across advanced sectors with innovation in machine tool design and smart manufacturing. Leading companies like ACE Micromatic, BFW, Jyoti CNC, HMT Machine Tools, Lakshmi Machine Works, AMS, and others are pushing the envelope in terms of precision, capability, and service.

For businesses (within India and globally) seeking CNC machines that are reliable, precise, and matched to modern demands (automation, complex geometries, material diversity, tight tolerances), Bangalore is increasingly a competitive option. As manufacturers here continue to invest in technology, scale, and quality, the future looks promising.