Affordable & Reliable Sheet Metal Fabrication in Bangalore

In today’s manufacturing and fabrication landscape, finding a partner that balances cost and quality is no small feat. Bangalore — often called India’s tech and industrial hub — is home to a vibrant ecosystem of sheet metal fabricators, many of which specialize in delivering affordable and reliable solutions to clients across sectors. Whether you are a startup, a small business, or a major industrial enterprise, this blog will guide you through what to look for, how to choose, and why Bangalore stands out.In today’s manufacturing and fabrication landscape, finding a partner that balances cost and quality is no small feat. Bangalore — often called India’s tech and industrial hub — is home to a vibrant ecosystem of sheet metal fabricators, many of which specialize in delivering affordable and reliable solutions to clients across sectors. Whether you are a startup, a small business, or a major industrial enterprise, this blog will guide you through what to look for, how to choose, and why Bangalore stands out.

Why Choose Bangalore for Sheet Metal Fabrication?

Before diving into how to find an affordable and reliable vendor, it helps to understand why Bangalore is a top choice for sheet metal work in India.

- Strong Industrial Base & Demand

Bangalore hosts industries in electronics, telecom, aerospace, and automotive. Many of these require custom metal enclosures, structural parts, frames, and more. This demand gives rise to a competitive environment among fabricators, helping drive cost‑efficiency. - Skilled Workforce & Technical Expertise

The city has numerous engineering colleges and technical institutes, producing talent that is familiar with CAD/CAM, CNC machinery, and precision manufacturing. Many shops invest in training and retain experience in sheet metal crafts. - Access to Modern Equipment & Technology

To stay competitive, fabricators in Bangalore often adopt advanced technologies: laser cutting, CNC punching, robotic welding, and computer‑aided design. These help reduce wastage, increase precision, and optimize turnaround time. - Logistics & Supply Chain Advantages

Bangalore’s connectivity by road, rail, and air helps in sourcing raw materials (sheets, plates, consumables) quickly, and shipping finished components to clients in India or for export. The proximity to material suppliers helps keep costs in control. - Competitive Market Pressure

With many fabricators operating, customers can compare quotes, capabilities, and references. This competitive pressure helps in keeping prices reasonable without compromising essential quality.

Because of these factors, Bangalore has emerged as one of the go-to destinations for sheet metal fabrication in India.

What “Affordable & Reliable” Really Means

When clients say they want “affordable and reliable” sheet metal fabrication, these are the core attributes they typically mean:

- Cost-effective — A fair price per component or assembly, with minimal overhead markup and optimized material usage.

- Consistent quality — Precision, repeatability, good tolerances, and low defect rates.

- Timely delivery — Meeting deadlines and milestones reliably.

- Transparent quoting & scope control — No hidden costs or surprises during execution.

- Good communication & support — Involvement during design, updates throughout the process, and responsive customer service.

- After-sales/service support — Repairs, modifications, rework, or maintenance when needed.

Any fabrication partner that can balance these is truly valuable.

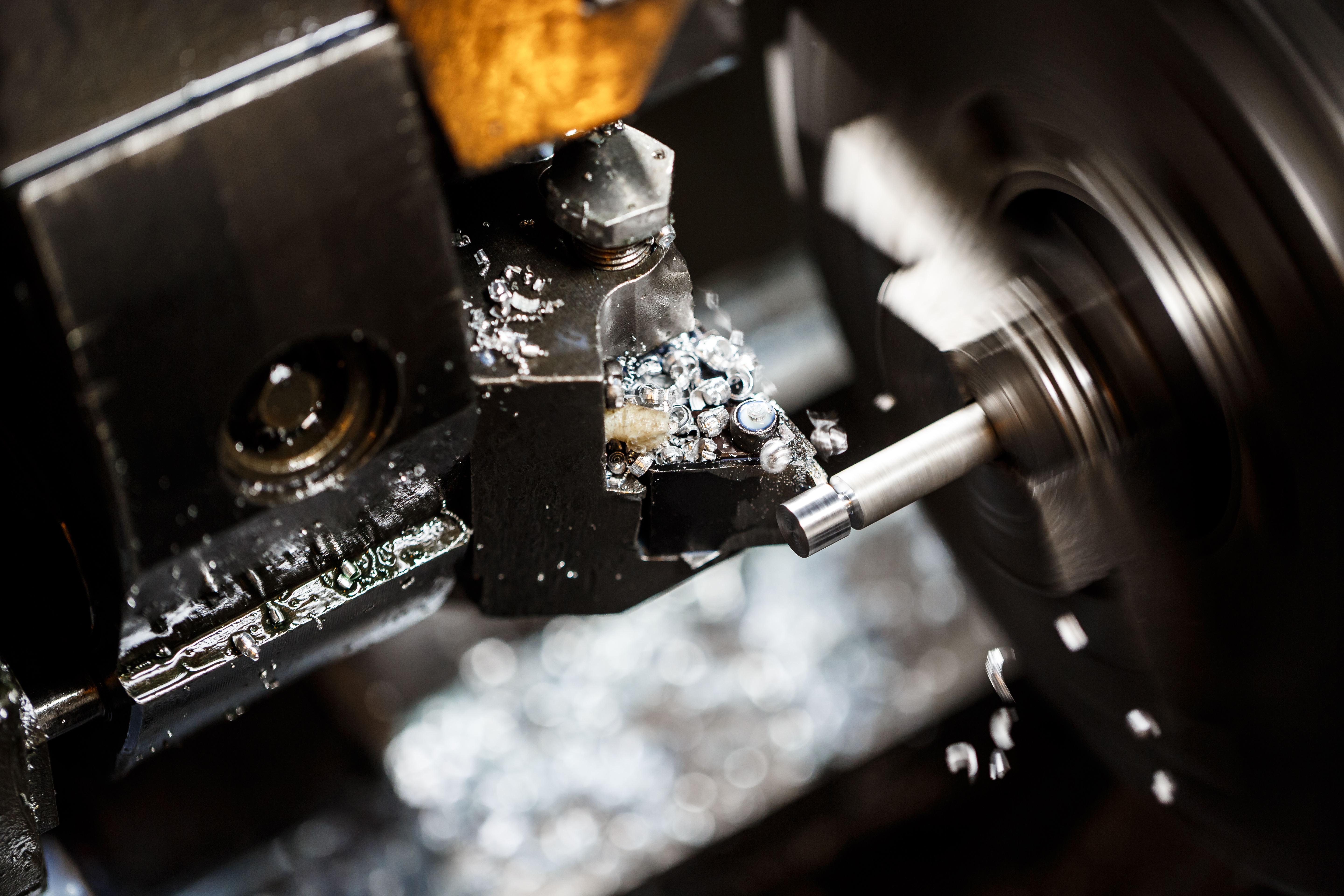

Key Services & Processes in Sheet Metal Fabrication

To understand where costs and reliability can vary, let’s look at the typical steps and services involved in sheet metal fabrication. A fabricator offering a full suite of services is more likely to be reliable, while specializing helps control costs.

- Design & Engineering / CAD Support

Many fabricators support or require you to submit CAD drawings (e.g. DXF, DWG, STEP). Some offer value-add services like design optimization, manufacturability feedback, or prototyping. - Material Procurement & Stocking

Common materials: mild steel (MS), CRCA, galvanized steel, stainless steel, aluminum, copper, etc.

A good shop maintains stock of standard sheet thicknesses and grades to reduce lead time. - Cutting & Profiling

Techniques include laser cutting, plasma cutting, waterjet, shearing, or CNC punching. The choice impacts cost, edge quality, and material utilization. - Bending / Forming

Press brakes, folding machines, or roll bending to give the sheet the desired angles, curves, or forms. - Stamping / Deep Drawing (if required)

For complex contours or high-volume parts, stamping or deep drawing may be used. - Welding & Joining

Processes like MIG, TIG, spot welding, brazing, or riveting are used to assemble components. - Finishing / Surface Treatment

Powder coating, painting, galvanizing, anodizing, or passivation are common finishes to protect and beautify the parts. - Quality Assurance / Inspection

Dimensional checks, visual inspections, NDT (non-destructive testing), or weld inspection as required. - Assembly & Packaging

Final assembly, fitment checks, packing, and shipping.

A fabricator that handles all these within one facility (a “one-stop shop”) offers more control, fewer handoffs, and potentially lower total cost compared to splitting across multiple vendors..jpg)

What Drives Cost — and How Affordable Shops Optimize

To distinguish truly affordable options from “cheap but unreliable,” it helps to know where costs come from and how shops optimize.

Cost Drivers

- Material costs

Sheet metal, especially higher grades like stainless steel, can be expensive. Poor nesting or waste increases cost. - Labor / Skilled manpower

Wages for skilled operators (CNC machine operators, welders, assemblers) are a significant component. - Machine usage & depreciation

Use of expensive equipment (lasers, press brakes, robotics) involves fixed costs and maintenance. - Setup & tooling

For new jobs, setup time, dies, jigs, and fixtures must be amortized. - Rework / defects

Mistakes cause scrap or rework, which drives up cost. - Logistics & handling

Moving sheets, handling heavy parts, packaging, and shipping can add overhead.

How Affordable & Reliable Shops Optimize

- Efficient nesting & sheet utilization

Use software to optimize cutting paths and reduce waste. - Standardization & modular design

Encouraging use of standard thicknesses and modular parts to reduce setup changes. - Batch production

Grouping orders to amortize setup and tooling costs. - Cross-trained workforce

Operators capable of handling multiple tasks reduce idle time. - Preventive maintenance

Avoiding breakdowns ensures smooth workflow and avoids delay penalties. - In-house finishing & QA

Avoid outsourcing finishing or inspection steps which add cost and risk. - Transparent quoting & change control

Clear quotations with line items for extras (holes, finish, tolerances) to avoid surprise costs mid-project.

Thus, a well‑run shop can deliver quality parts while maintaining reasonable margins.

How to Choose the Right Fabricator in Bangalore

Here’s a checklist and guidance to help you pick a partner that is truly affordable and reliable.

|

Criteria |

What to Check |

Why It Matters |

|

Experience / Portfolio |

Ask for samples, case studies, client names |

Shows they’ve done similar work |

|

Equipment / Capability |

Laser cutting, CNC press brakes, welding, finishing |

More capabilities reduce outsourcing and handling risk |

|

Quality certification & processes |

ISO, documented QA procedures, inspection logs |

Ensures they follow discipline |

|

Quotation clarity |

Line‑item pricing for material, labor, finishing, extras |

Avoid hidden costs |

|

Communication & responsiveness |

Prompt replies, design feedback, progress updates |

Crucial for coordination |

|

Turnaround & lead time |

Ask typical timelines for similar jobs |

Helps you align your project schedule |

|

After-sales & support |

Warranty, ability to rework, maintenance |

For long-term reliability |

|

Client references / reviews |

Past clients, testimonials, Google / Justdial / industry contacts |

Real feedback gives confidence |

Also, try a small pilot order first. If the vendor delivers on that, scale up.

Notable Sheet Metal Fabricators in Bangalore

Here are a few established names in Bangalore’s sheet metal fabrication landscape (for reference and benchmarking):

- Lamiera Technologies — They emphasize precision metal fabrication, equipped with laser cutting, CNC punch press, and bending setups.

- PRK Fabricators — Offers enclosures, machine guards, control panels, etc., with in‑house welding, bending, shearing.

- Fine Punch Fab — ISO 9001 certified, with extensive shop space and full CNC metal fabrication capabilities.

- PM Industries, Bengaluru — A full-service fab shop handling precision metal fabrication, structural fabrication, enclosures, turnkey projects.

- SP Fab — A firm in Bangalore with decades of experience servicing automotive, machinery, and infrastructure clients.

- Hosmetal Fab — Located in the Electronic City area, they offer direct factory pricing and good flexibility.

Visiting or reviewing their portfolios can help you better understand the market norms in Bangalore.

Sample Project Flow: From Design to Delivery

Let’s walk through a hypothetical project to illustrate how an affordable & reliable fabrication shop might handle it.

- Client Inquiry & Design Submission

You send a CAD file (e.g. STEP, DWG) or rough sketches. The shop responds with design review feedback. - Quotation & Scope Definition

The shop gives you a line‑item estimate (material, cutting, bending, welding, finishing, assembly). You negotiate, adjust tolerances or finishes as needed. - Material Ordering & Preparation

They source or use in‑stock sheet-metal. If custom grade, order lead time is accounted for. - Cutting & Nesting

They optimize nesting (efficient layout) and send the part to laser cutter or punch press. - Forming / Bending

Use of CNC press brakes or folding machines to shape the parts. - Welding / Joining

Welding, riveting, or fasteners as required. Jigs or fixtures help improve repeatability. - Inspection & Rework

Dimensional checks, visual inspection, corrective adjustments. - Finishing & Surface Treatment

Powder coating, painting, galvanizing, etc. - Final Assembly & Packing

If the part is part of a subassembly, they assemble and test fit. Then they package securely and dispatch. - Delivery & Support

After delivery you may send feedback or request minor fixes or replacement pieces.

This complete flow ensures accountability and helps you track where costs and reliability are determined.

Tips to Get the Most Value

While selecting a fabricator is key, here are extra tips to ensure you get the best outcome:

- Simplify the design where possible

Use fewer bends, reduce unique parts, avoid extremely tight tolerances unless necessary. - Standardize materials & thicknesses

If you stick to commercially available, common sheet gauges, the vendor likely already has stock. - Batch orders / scale up

Larger or grouped orders allow economies of scale and amortization of setup costs. - Clear specification of tolerances & finish up front

If you’re flexible, letting the vendor choose less tight tolerances or simpler finishes reduces cost. - Ask for design for manufacturability (DFM) input

Good fabricators will suggest small changes to improve yield or reduce cost. - Inspect samples first

Before full production, accept a few prototype pieces to validate fit and quality. - Build long-term relationships

Vendors willing to commit to longer contracts may offer better pricing and priority in scheduling.

Challenges & How Bangalore Shops Overcome Them

Even with all the advantages, there are challenges. Here’s how Bangalore’s fabricators mitigate them:

- Fluctuating raw material prices

Vendors may hedge, buy in bulk, maintain safety stock, or pass small fluctuations via escalation clauses. - Maintaining quality across batches

Strong QA processes, calibration of machines, and operator training are essential. - Meeting tight deadlines

Efficient workflow, backup machines, and flexible scheduling help meet critical demands. - Keeping overheads low

Lean shop layouts, shared utilities, continuous improvement practices help keep shop overhead in check. - Handling small orders or custom jobs

Not all shops accept tiny jobs. The ones that do often bundle such jobs or charge minimum setup fees to cover overhead.

If you request quotes from a few vendors in Bangalore, compare not just price but capabilities, lead time, and reputation to avoid surprises.

Conclusion

In a world where “cheap” and “quality” often seem at odds, Bangalore’s sheet metal fabrication industry offers a sweet spot: affordable & reliable services delivered by experienced shops equipped with modern tools and driven by competition. If you follow a systematic approach — evaluate capabilities, request transparent quotes, start with prototypes, and build relationships — you can leverage Bangalore’s strengths and get high-quality fabricated metal parts without breaking the bank.