How Sheet Metal Fabrication Manufacturers Are Shaping Modern Industry

In the world of manufacturing, sheet metal fabrication may seem like a traditional process—cutting, bending, welding, forming. But today, sheet metal fabrication manufacturers are doing more than just producing panels and frames. They are at the heart of innovation, efficiency, and transformation across industries: from automotive and aerospace to construction, electronics, renewable energy, and more. In this post, we explore how sheet metal fabrication manufacturers are influencing modern industry through technology, sustainability, design, and market forces.In the world of manufacturing, sheet metal fabrication may seem like a traditional process—cutting, bending, welding, forming. But today, sheet metal fabrication manufacturers are doing more than just producing panels and frames. They are at the heart of innovation, efficiency, and transformation across industries: from automotive and aerospace to construction, electronics, renewable energy, and more. In this post, we explore how sheet metal fabrication manufacturers are influencing modern industry through technology, sustainability, design, and market forces.

1. Rapid Growth & Increasing Demand

The market for sheet metal fabrication Manufacturers services is expanding. Global demand for fabricated metal parts is rising, driven by several end‑use industries that require precision, lower weight, complex geometries, custom components, and faster turnaround.

- Automotive & Aerospace: Lighter, stronger metal parts (aluminum alloys, high‑strength steels) are essential to reduce weight, improve fuel efficiency, and maintain structural integrity.

- Construction & Urban Infrastructure: As urbanization accelerates, demand for durable, corrosion‑resistant sheets, roofing, cladding, facades, supports, and infrastructure components increases. Electronics, Medical Devices, & Custom Equipment: These require components with tight tolerances, complex designs, and often smaller volume runs with higher precision. This growth is pushing manufacturers to modernize their processes, invest in new technologies, and refine their business models to stay competitive.

2. Advances in Technology: Automation, Digitalization & AI

One of the biggest ways sheet metal fabrication manufacturers are shaping modern industry is by embracing advanced technologies.

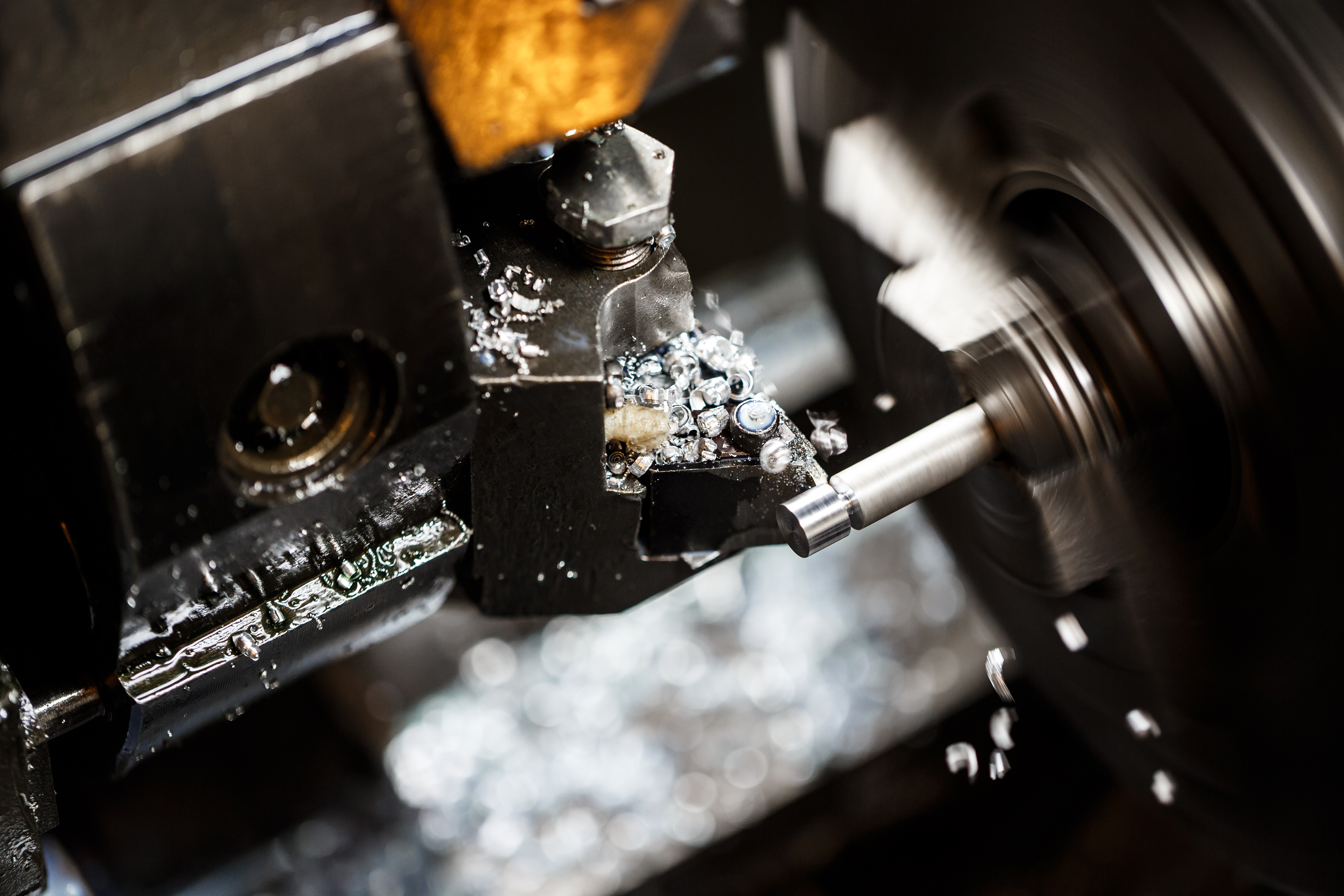

Automation & Robotics

- Robots are increasingly used for cutting, welding, bending, forming, material handling, assembly. This reduces labor‑intensive steps, minimizes human error, speeds up production, and enhances safety.

- Automated press‐brake cells, robotic arms, CNC machines, and integrated fabrication cells are becoming more widespread. These systems are often governed by software that optimizes workflows.

Digital Design & Industry 4.0

- CAD/CAM (computer‑aided design / manufacturing) tools are standard. Designers can simulate, test, adjust designs digitally before committing to production. This reduces physical prototyping, saves material costs, and ensures designs meet specifications.

- IoT (Internet of Things) sensors on machines allow real‑time monitoring of production (machine health, yield, throughput). Predictive maintenance helps avoid downtime. Data analytics let manufacturers spot inefficiencies in processes.

Additive Manufacturing and Digital Sheet Forming

- Additive manufacturing (3D printing) is starting to be used, especially for complex dies, small‑batch, custom parts, or prototyping. It helps reduce material waste and lead times.

- Digital sheet metal forming: new technologies allow sheet metal to be formed on demand using digital (software‑controlled) tooling rather than traditional dies and molds. This gives greater flexibility, reduces setup times, and supports lower volumes.

3. Materials & Design Innovations

Modern industries demand better materials and more creative, optimized designs. Sheet metal manufacturers are adapting and pushing the envelope here too.

Lightweight, High‑Strength, and Specialty Materials

- Use of aluminium alloys, high‑strength steel, stainless steel, even titanium or exotic alloys in niche cases, to balance weight, strength, corrosion resistance, and cost.

- Advanced coatings, surface finishes, treatments to increase durability, aesthetics, resistance to wear and environmental damage.

Complex Geometries & Customization

- Customers increasingly want bespoke components—non‑standard shapes, curvatures, perforations, folds, etc. Sheet metal fabrication methods (laser cutting, water jet, bending, stamping, incremental forming) allow complex forms.

- Rapid prototyping and small batch runs are more viable now because of digital tools and flexible tooling.

4. Sustainability, Cost Efficiency & Waste Reduction

Sustainability isn’t just a buzzword—it’s increasingly central to how manufacturers operate and what customers expect.

- Material waste reduction: through better planning, nesting algorithms in cutting (optimizing how sheets are cut to minimize scrap), reuse or recycling of scrap metal.

- Energy efficiency: More efficient machines, lasers, presses; sometimes renewable energy sources; optimizing process flows to reduce idle time and energy draw.

- Eco‑friendly materials and coatings: use of recyclable metals, corrosion‑resistant materials that last longer and require less maintenance.

5. Impacts on Industry Sectors

The influence of sheet metal fabrication spans multiple sectors; here are how things are changing:

Automotive

Automotive manufacturers need lightweight components for fuel efficiency / electric vehicle range, precise parts for safety systems, aesthetic panels, etc. New sheet metal techniques (high strength steel, aluminium, hybrid metals) help reduce weight while maintaining strength. Automated welding, laser cutting reduce cycle times.

Aerospace & Defense

Demand for strict tolerances, lightweight alloys, high durability. Forming techniques like hydroforming or superforming are being used. Quality control is critical; advanced inspection (vision systems, sensors) are used.

Construction & Infrastructure

Sheet metal is used for cladding, roofing, structural supports, façades, architectural features. Demand for corrosion resistance, high durability, aesthetic finishes. Prefab construction is growing; sheet metal components need to be precise and integrated.

Electronics, Medical & Custom Products

Here small volumes, high precision, complex geometries, tight tolerances are critical. Rapid prototyping, custom tooling, digital workflows assist these sectors.

6. Business Models & Market Dynamics

Manufacturers are evolving not just technically, but also in how they deliver goods and services.

- On‑demand & Custom / Small‑Batch Manufacturing: Instead of large mass runs, there’s increasing demand for small batches, custom parts. Manufacturers who can provide flexible, fast turnarounds are in demand.

- Outsourcing / Contract Fabrication: Many companies prefer to outsource sheet metal components rather than build in house, so providers of fabrication services are growing in importance.

- Global Competition and Localization: While there is outsourcing globally, there is also demand for localized suppliers who can reduce lead times, shipping costs, and respond quickly. Regionally‐focused manufacturers who adopt modern tech often gain the edge.

- Regulatory & Performance Standards: Industries like aerospace, automotive, medical require strict conformity, certifications, traceability. Manufacturers must invest in quality control, traceability, certifications.

7. Challenges & How Leading Manufacturers Are Addressing Them

Of course, the transformation isn't without challenges. The way manufacturers respond to them often defines their success in shaping modern industry.

Skilled Labor Shortage

- Finding skilled welders, machinists, operators is a challenge. Many manufacturers invest in training, apprenticeships, use of automation/cobots to reduce dependency on manual skilled labor.

Fluctuating Material Costs & Supply Chains

- Prices for steel, aluminum, etc., can vary a lot. Supply chain disruptions (pandemics, trade issues, raw material shortages) increase risk. Manufacturers are diversifying suppliers, keeping strategic stock, optimizing material usage.

High Upfront Investment

- Advanced machines (laser cutters, robotic arms, digital sheet forming tools) are expensive. ROI depends on volume, precision, demand. Smaller players may find it tough to invest. Some address this via shared fabrication facilities, contract manufacturing, leasing equipment, or focusing on niche/custom work.

Technology Adoption & Integration

- Integrating new technologies (IoT, AI, digital design, automation) requires not just hardware, but software, training, process redesign. Data collection, connectivity, predictive maintenance all need reliable systems. Leading manufacturers invest in digital infrastructure and staff skills.

Sustainability & Environmental Regulations

- New regulations often demand lower emissions, better waste management, sustainable materials, energy efficiency. Manufacturers are evaluating environmental footprints, seeking certifications, and adopting green processes.

8. The Future: What to Expect

Looking ahead, sheet metal fabrication manufacturers will continue to push boundaries. Some likely developments include:

- More Digital Sheet Forming Technologies: Making the shift from traditional die‐based forming to more flexible, on‑demand digital forming.

- Greater Use of AI & Machine Learning: For optimization, predictive quality control, defect detection, and process improvement. Real‑time monitoring, self‑adjusting machines.

- Enhanced Customization & Personalization: Customers will expect even more bespoke parts, faster prototyping, aesthetic possibilities.

- Sustainability as Core Strategy: Not just as compliance, but as a competitive advantage. Circularity of materials, renewable energy usage, lower carbon footprints.

- Hybrid Manufacturing: Combining additive and subtractive processes, smart forming, hybrid materials (metal + composites), coatings.

.jpg)

Conclusion

Sheet metal fabrication has come a long way from its roots of purely manual, labor‑intensive operations. Today’s sheet metal fabrication manufacturers are central to innovation in modern industry. Through automation, digitalization, materials advancement, sustainability efforts, and flexible business models, they’re enabling sectors like automotive, construction, aerospace, electronics, and more to grow faster, produce higher quality, and meet demanding specifications.For businesses that use sheet metal components, finding a manufacturer who keeps pace with these trends means better parts, faster lead times, lower cost, and more design freedom. For manufacturers themselves, the race is on: adapt and innovate, or be left behind.