Leading Sheet Metal Fabrication Services in Bangalore

Leading Sheet Metal Fabrication Services in Bangalore. In the heart of southern India, Bangalore has long been known as a hub for technology, innovation, and industrial growth. In recent years, another industry has been steadily making its mark here: sheet metal fabrication. As demand continues to grow across industries such as automotive, electronics, infrastructure, telecom, aerospace, and more, sheet metal fabrication services in Bangalore are stepping up with advanced capabilities, precision, and reliability. This blog explores what makes the city a leader in this field, who the major players are, what technologies are involved, and where the sector is headed.

What is Sheet Metal Fabrication?

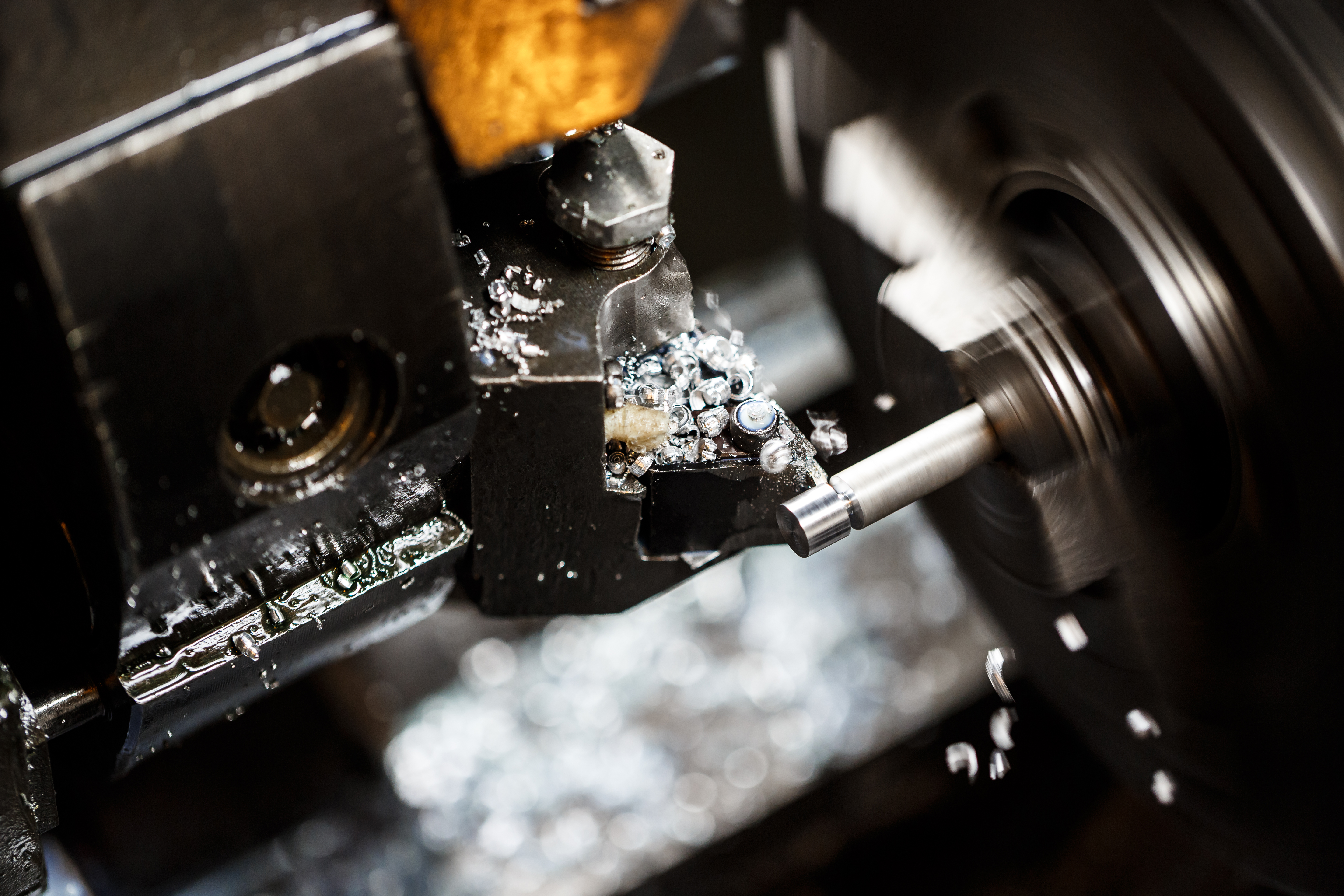

Sheet metal fabrication involves taking thin sheets of metal (often steel, stainless steel, aluminium, or other alloys) and shaping them via various processes—cutting, bending, forming, welding, finishing—to create components, enclosures, structures or artistic/design work. The processes require precision, strength, surface treatment, and often tight tolerances. Whether for small bespoke parts or large-scale industrial assemblies, sheet metal fabrication is foundational to many manufactured goods.

Why Bangalore for Sheet Metal Fabrication?

Several factors converge to make Bangalore an attractive centre for sheet metal work:

- Industrial and Technological Ecosystem

Bangalore already has strong links with electronics, telecom, defence, aerospace, and automotive sectors. The proximity of these industries creates demand, stimulates innovation, and ensures that fabrication units invest in up-to-date machinery and quality control. - Skilled Workforce & Technical Expertise

With numerous engineering colleges, technical institutes, and manufacturing training programs, the city has a steady stream of engineers, welders, machinists, and technicians who understand advanced metalworking processes. This helps fabricators maintain quality, adopt new technologies, and deliver more sophisticated products. - Infrastructure & Connectivity

Ease of procuring raw materials, shipping finished goods, availability of utilities, industrial zones—all contribute. Good road, rail, and air connections make it easier to serve domestic markets and also export if needed. - Cost‑Effectiveness & Competitive Pricing

Due to competition among many fabricators, combined with local supply chains, Bangalore companies often are able to deliver quality work at prices that are competitive when compared to many other Indian cities and even overseas vendors. - Adoption of Modern Technologies & Standards

Fabricators in Bangalore don’t just rely on traditional techniques; many have adopted CNC (Computer Numerical Control) machines, laser cutters, automated bending machines, CAD/CAM design tools, welding robots or precision welding, finishing processes, etc., along with quality certifications, which help in meeting demanding standards (domestic and international).

Key Services & Capabilities You’ll Find

To understand what “leading sheet metal fabrication services” means in Bangalore, here are the kinds of capabilities those leading firms usually offer:

|

Process / Capability |

What It Involves |

Why It Matters |

|

Cutting (Laser, Plasma, Shearing, Water‑jet) |

Precisely cutting sheets into parts. Laser cutting is especially common for detailed designs and tight tolerances. |

Minimizes waste, provides clean edges, allows complex shapes. |

|

Bending / Forming |

Using press brakes, folding machines, stamping or deep drawing to bend or form shapes. |

Many components require precise bends; forming makes parts stronger and fits functional requirements. |

|

Punching / Turret Punch Presses |

Punching holes or slots, shapes out of sheet, often repetitive parts. |

Good for high volume, efficient for designs with standard patterns. |

|

Welding & Assembly (MIG, TIG, Spot, Arc etc.) |

Joining parts together, assembling components, integrating fasteners/hardware. |

Strong joints, durability, structural integrity. |

|

Finishing / Surface Treatment |

Powder coating, painting, anodizing, galvanising, plating, polishing etc. |

Aesthetic appeal, corrosion resistance, longer life. |

|

Design & Prototyping |

CAD/CAM tools, sometimes simulation, rapid prototyping. |

Helps in ensuring design manufacturability, cost estimation, reducing iterations. |

|

Quality Control & Certifications |

Inspection, testing, adherence to ISO or other standards. |

Ensures reliability, zero‑defect outputs, meeting client and regulatory requirements. |

Notable Companies & What They Offer

Here are some of the leading sheet metal fabrication companies or units in Bangalore and what makes them stand out:

- Shree Sigma Laser

Located in Bangalore, Shree Sigma Laser offers high‑precision CNC laser cutting, bending, and welding. They support a variety of metals: mild steel, stainless steel, aluminium, copper, brass, etc. Their machines can handle sheet sizes up to around 3000mm × 1500mm, with good thickness. - PRK Fabricators Pvt Ltd

Established in 1989, PRK is a trusted name. They manufacture sheet metal components, enclosures for electrical/electronic industries, and components for food processing, medical machinery, etc. Their capabilities include bending, punching, MIG/TIG welding, and a commitment to zero defects. - Sp‑Fab (SP Fab)

SP Fab focuses on automotive, machinery, construction, and infrastructure industries. They do custom sheet metal fabrication, precision bending and welding, and specialized treatments for corrosion resistance. - Metalpro India

This company handles architectural and industrial fabrication including laser cutting metals, perforated metals, expanded metals, facades etc. They emphasize custom work and being able to meet varied design requirements. - Lamiera Technologies

Since 2010, they have been delivering precision sheet metal fabrication. Their facilities include high‑speed and precise performing machines, large press‑brakes, punch presses, etc. They focus also on quality, meeting customer’s technical requirements. PM Industries

Acting as a full‑service fabricator, PM Industries offers precision metal fabrication, structural fabrication, enclosure fabrication, tanks & vessels, turnkey projects, and finishing. Their offerings also include design support, testing, painting etc. - Levy Punch Technologies

They specialize in custom sheet metal parts: panel boards, enclosures, automobile spare parts, textile machinery parts, etc. They also provide design services (CAD/CAM), prototyping, mass production.

Market Trends & Drivers

Understanding what’s driving demand and what trends are shaping the future helps both clients and fabricators plan better. Here are some of the key market trends in Bangalore (and India more broadly):

- Rising Demand from End‑Use Industries

The automotive, construction, infrastructure, electronics, aerospace, defence, and renewable energy sectors are increasingly sourcing locally fabricated sheet metal parts. Government schemes (e.g. Make in India) and infrastructure pushes are significant contributors. - Growth in Precision and Customization

Customers are no longer satisfied with off‑the‑shelf parts; they want tailor‑made solutions with exact specifications. This drives demand for firms that can do prototyping, R&D, design, and accommodate complex geometries. - Adoption of Advanced Technologies

Laser cutting, CNC punching, robotic welding, automated bending, CAD/CAM, ERP integration — these are becoming more common. They improve speed, reduce errors, allow for better control, and help in scaling. - Focus on Quality and International Standards

New clients (including multinational companies) expect ISO certifications, documented quality control, traceability, consistency. This is pushing many fabricators to upgrade both process and people. - Sustainability and Efficiency

Reducing waste (material, energy), more efficient machines, eco‑friendly surface finishes, recycling scrap metal—these are gaining importance. Also, optimizing designs to use less material, lower weight, etc. - Lead Times & Supply Chain Efficiency

The importance of shorter lead times, reliable delivery, and well‑managed supply chains is ever increasing. Fabricators in Bangalore who can guarantee prompt delivery and coordination (raw materials, component sourcing, finishing, transport) get a competitive edge.

Challenges

Of course, the sector also faces some hurdles and constraints. Some of these are:

- Raw Material Price Volatility

Steel, aluminium, alloys prices can fluctuate, which can impact cost estimates, especially for larger orders. - Skilled Labour Shortage for High Precision Work

While there is a good base workforce, finding people with very high skill levels (for extremely tight tolerances, advanced finishing, sophisticated welding, etc.) can sometimes be a challenge. - Maintaining Quality Across Volume

For large orders, consistency can be harder to maintain. Surface finish, weld quality, dimensional tolerances can sometimes drift. - Competition & Margin Pressure

With many players in Bangalore and surrounding regions, competition is strong. Clients often demand lower prices, which can squeeze margins. - Regulatory, Environmental, Safety Compliance

As standards rise, fabricators need to invest in safety, waste handling, emission control, worker protections, etc., which add to costs. - Technology Upgradation Costs

Acquiring advanced machines (robotic welders, laser cutters, automated bending machines) and integrating software (CAD/CAM, ERP etc.) require capital, maintenance, trained staff, which can be a barrier for smaller workshops.

How to Choose a Good Fabrication Service in Bangalore

If you are a business or engineer needing sheet metal fabrication, here are criteria to look for to select the right partner:

- Capabilities & Equipment

Does the fabricator have the machinery needed for your job? (Laser cutting, bending, finishing etc.) What are the max sizes/thickness they can handle? - Quality Assurance

Certifications (ISO etc.), practices (inspection, testing), ability to provide sample parts or prototypes. - Experience in Your Industry

If you are in automotive, telecom, medical, etc., choose someone who has successfully delivered in that sector. - Design Support

Capability to accept/produce CAD designs, to do prototyping or suggestions to optimize manufacturability. - Lead Time & Reliability

Dependability on delivery schedules, ability to handle urgency, flexibility in project scaling. - Cost vs Value

It’s not just about lowest cost. Value also includes durability, finish, after‑sales support, possible maintenance etc. - After‑Sales / Finishing / Assembly Services

Does the fabricator assemble, do finishing (painting, coating etc.), installation or just supply parts? - Sustainability / Environment & Safety Practices

If that matters for your business or brand, check fabricator’s safety record, waste handling, environmental compliance etc.

Future Outlook

Looking forward, the sheet metal fabrication sector in Bangalore appears well‑positioned for continued growth. Some features likely to shape its path:

- Increased Automation & Smart Manufacturing

More adoption of robotics, IoT sensors, automated material handling, condition‑based monitoring. - Lightweight / New Materials

As industries like aerospace, EVs, renewable energy demand lighter weight, stronger materials, new alloys or composites may find greater use. - Digital Transformation

More firms will integrate CAD/CAM, ERP, possibly simulation tools (finite element, thermal etc.), digital twins, etc., to speed up design‑to‑production cycles and reduce errors. - Export & Global Supply Chains

As Indian manufacturing competitiveness improves, more firms will aim for export contracts and international standard compliance. - Sustainability & Green Fabrication

More emphasis on minimizing waste, energy efficiency, responsible sourcing, perhaps even carbon‑footprint certifications.

Case Example: Shree Sigma Laser’s CNC Capabilities

To illustrate how some of the leading firms operate:

- Sheet Size & Material: They handle up to 3000mm × 1500mm sheets, with thickness ranges (depending on metal) up to ≈ 16mm for mild steel, 10mm for stainless steel, 8mm for aluminium etc.

- Diverse Metals: Mild steel, stainless steel, aluminium, copper, brass, and other alloys.

- Precision Cutting & Welding: High accuracy laser cutting, bending, welding (MIG, TIG, spot, arc etc.), along with assembly and QC.

Market Size & Growth

- The India sheet metal fabrication market was estimated at USD 152.3 million in 2024 with projections to reach about USD 262.1 million by 2033, growing at a CAGR of ~5.76 %.

- More broadly, the metal fabrication market (which includes heavy structures, architectural, industrial etc.) is valued in the billions USD, and demand is escalating with growing infrastructure projects, automobile production, electronics manufacturing, and so on.

Conclusion

Bangalore’s rise as a centre for leading sheet metal fabrication services is no accident. The combination of demand, technological adoption, skilled manpower, modern infrastructure, and competitive ecosystem has enabled firms here to deliver high quality, precision, and reliable service across a broad spectrum of industries.

Whether you are a startup needing a small batch of custom enclosures or a large OEM looking for structural fabrications, Bangalore offers a wide range of capable service providers. The key is to understand your requirements well (materials, tolerances, finishes, timelines) and choose a partner that aligns with your quality, cost, and delivery expectations.