From Design to Delivery: Seamless Sheet Metal Fabrication with Zeometrix in Bangalore

Introduction: The Zeometrix Commitment to Seamless Fabrication

Sheet metal fabrication is the backbone of modern industry from the sleek enclosures in data centers to critical components in the aerospace and automotive sectors. In a rapidly expanding industrial hub like Bangalore, the demand for precise, reliable, and seamless sheet metal fabrication in Bangalore is higher than ever. Companies are looking for skilled partners who can deliver high-quality custom metal solutions with efficiency and precision to meet the needs of various industries.

At Zeometrix, we understand that "fabrication" is more than just cutting and bending metal. It is a comprehensive, end-to-end process that starts with an idea and ends with a perfect, ready-to-use component. Our promise to our Bangalore clients is simple: a seamless experience from design concept to final delivery. We eliminate the communication gaps, quality compromises, and logistical headaches that plague traditional fabrication pipelines.

This article walks you through the integrated, five-stage process that defines the Zeometrix advantage and solidifies our position as the trusted fabrication partner in the Silicon Valley of India.

Phase I: The Precision Blueprint – Design & Engineering

The success of any fabricated part is locked in the initial blueprint. A flawless design phase is the foundation of a seamless process, preventing costly errors, delays, and material waste down the line.

Collaborative Design for Manufacturability (DFM)

Many fabrication projects stall because a beautiful design is not practically manufacturable. Zeometrix bridges this gap through a rigorous Design for Manufacturability (DFM) process. Our expert engineers in Bangalore work directly with your design team to:

- Material Selection: Advise on the optimal sheet metal—whether it’s stainless steel for corrosion resistance, mild steel for structural applications, or aluminum for lightweight needs—based on the component's final application.

- Tolerance Review: Analyze critical dimensions and tolerances to ensure the design is achievable using our high-precision CNC equipment (Laser Cutting, Punching, Bending).

- Cost Optimization: Suggest minor design modifications (e.g., standardizing bend radii or nesting parts for better material usage) that can drastically reduce production costs without compromising function.

The Zeometrix Difference: We don't just accept CAD files; we enhance them. Our iterative design process ensures the digital model is perfect before a single piece of metal is cut.

Phase II: High-Tech Processing – Cutting & Forming

Once the design is validated and signed off, the raw sheet metal moves into our state-of-the-art manufacturing facility for sheet metal fabrication in Bangalore. This is where high-precision CNC (Computer Numerical Control) technology takes center stage.

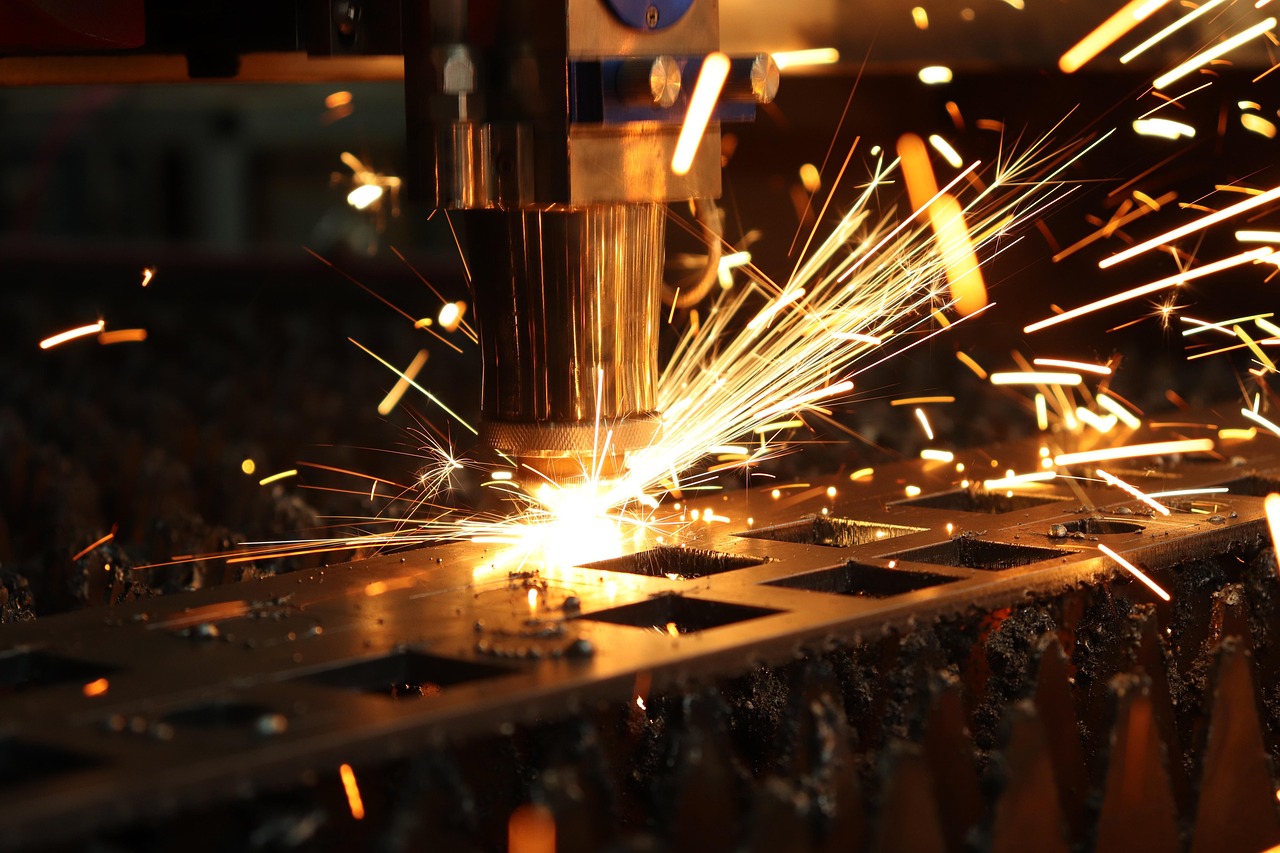

A. Cutting: The Foundation of Accuracy

Precision cutting is the first critical step. Our facility employs a range of technologies chosen specifically for material type, thickness, and required tolerance:

- CNC Laser Cutting: The gold standard for intricate shapes and high-speed processing. Our advanced fiber laser cutters deliver extremely tight tolerances and a smooth edge finish, minimizing the need for secondary processes.

- CNC Turret Punching: Ideal for high-volume production of parts requiring multiple holes, slots, or repetitive features. This method is exceptionally fast and cost-effective for medium-to-thin gauge material.

- Shearing & Waterjet: Utilized for simple, straight cuts (shearing) or for materials that are heat-sensitive or particularly thick (waterjet).

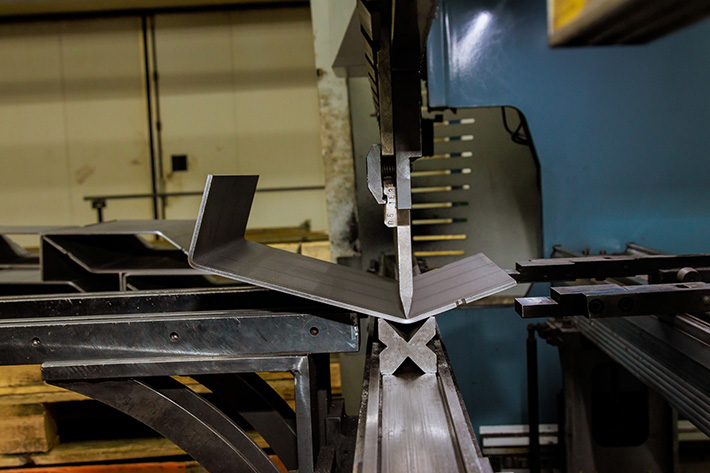

B. Forming: The Art of the Bend

The flat-cut profile is transformed into a 3D component using advanced CNC Press Brakes.

- CNC Bending/Press Brakes: Our computer-controlled press brakes ensure every bend angle is accurate, repeatable, and compensated for material properties (like spring-back). This consistency is vital for subsequent assembly phases.

- Rolling & Stamping: For parts requiring complex curves (rolling) or high-volume, repetitive deformation (stamping), we utilize specialized machinery to achieve the specified geometry with minimal material stress.

Phase III: Structural Integrity – Welding & Joining

Components often consist of multiple fabricated pieces that must be joined into a cohesive, structurally sound assembly. Our certified welding department is where these pieces become a robust final product.

- Certified Welding Expertise: We employ certified welders proficient in multiple techniques, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Spot Welding.

- TIG Welding is primarily used for precision work on stainless steel and aluminum where high cosmetic finish and critical integrity are required.

- MIG Welding is utilized for faster assembly on heavier gauge mild steel where speed and strength are prioritized.

- Assembly and Hardware Integration: Beyond welding, we handle all necessary component integration, including hardware insertion (e.g., nutserts, studs), riveting, and bonding, ensuring a 'plug-and-play' solution upon delivery.

Phase IV: The Final Touch – Finishing & Quality Assurance

The finish of a component is more than aesthetic; it dictates its durability, function, and longevity, especially in Bangalore’s varied industrial and urban environment. Zeometrix provides a full range of in-house and partnered finishing services.

Comprehensive Surface Treatments

- Powder Coating: The most popular choice for durable, long-lasting color and protection. We offer a vast palette and various textures, ensuring superior resistance to chipping, scratching, and corrosion.

- Plating & Anodizing: Services like zinc plating (for sacrificial corrosion resistance on steel) and anodizing (for enhancing the natural protective layer of aluminum) are managed efficiently to meet specific standards.

- Pre-Finish Prep: All parts undergo rigorous deburring, grinding, and cleaning processes to ensure optimal adhesion for the chosen finish, eliminating flaws that can compromise quality.

Zero-Defect Quality Control (QC)

Our commitment to seamless delivery means a zero-tolerance policy for defects. Our quality assurance procedures are integrated at every stage:

- In-Process Checks: Operators check key dimensions after cutting and bending.

- First-Article Inspection (FAI): The first part of any production run is subjected to a full dimensional check against the original CAD file.

- Final Inspection: Before packaging, every component is visually and dimensionally inspected against the client’s specifications, ensuring the correct finish, hardware, and packaging requirements are met.

Phase V: The Local Advantage – Logistics and Delivery in Bangalore

The "Delivery" part of our promise is just as critical as the "Design." In a bustling metropolis like Bangalore, efficient logistics and local accountability are paramount.

Why Local Expertise Matters

Choosing a local partner like Zeometrix in Bangalore offers distinct, measurable advantages:

- Accelerated Lead Times: Proximity drastically cuts transit time, allowing your project to move from our floor to your assembly line faster than any long-distance supplier.

- Logistical Reliability: We manage local dispatch and navigate regional infrastructure, ensuring on-time delivery without the risk of inter-state or national shipping delays.

- Direct Communication & Site Visits: Need to check on a large order? Our local presence allows for quick, face-to-face meetings and on-site inspection of work-in-progress, giving you total control and peace of mind.

- Regional Compliance: We are intimately familiar with the material standards, regulations, and industry-specific requirements within the Karnataka region, ensuring all fabricated products are fully compliant.

The Zeometrix Integrated Ecosystem: Your True Partner

At Zeometrix, we don't just want to be your vendor; we want to be an extension of your manufacturing capability. Our Design to Delivery model is an integrated ecosystem built on technology, expertise, and a deep commitment to the Bangalore industrial community.

By centralizing all critical stages—from DFM and cutting to welding and finished delivery—we provide a single point of accountability, streamline your supply chain, and guarantee precision, speed, and cost-effectiveness.

Are you ready to transform your sheet metal fabrication workflow from a series of disjointed steps into a seamless, high-efficiency operation?

Contact Zeometrix today to discuss your next project in Bangalore and experience the true meaning of seamless fabrication.