Experience World-Class Sheet Metal Fabrication Built for Bangalore’s Fast-Growing Industries with Zeometrix

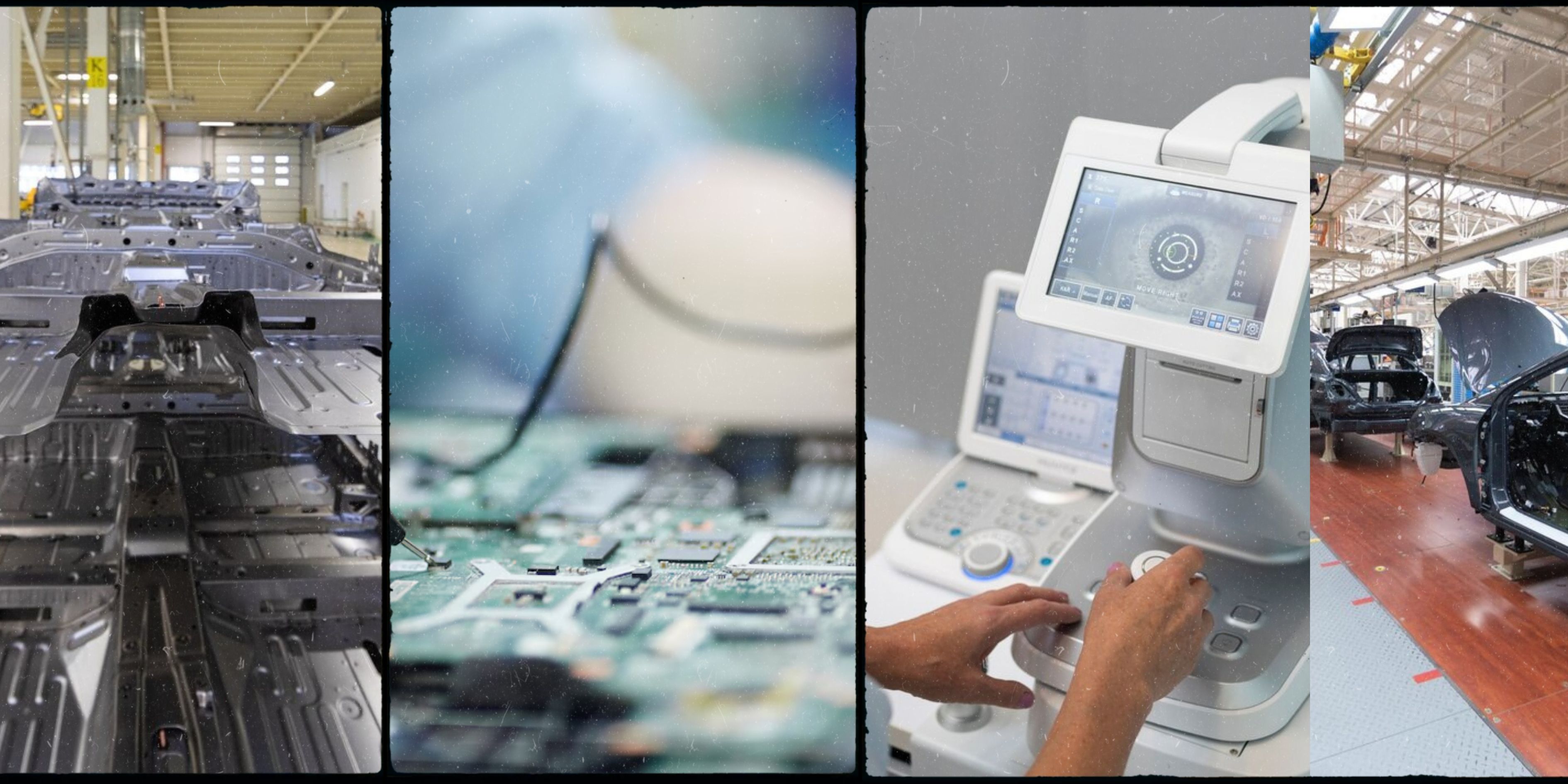

Sheet metal fabrication has emerged as one of the most vital processes in modern manufacturing, enabling industries to transform flat metal sheets into precise, durable components through cutting, bending, forming, welding, and finishing. This technology-driven discipline is especially significant in a fast-growing industrial hub like Bangalore, where the demand for high-quality, customizable metal parts spans sectors from aerospace and EVs to medical devices and electronics.

Companies such as Zeometrix are at the forefront of this transformation, leveraging advanced CNC machinery, laser cutting systems, robotic welding, and automated production workflows. Their state-of-the-art facilities and engineering expertise allow them to deliver unmatched precision, consistency, and innovation that today’s industries require. As one of the pioneers in robotic welding and automated sheet metal manufacturing in Bangalore, Zeometrix continues to raise the benchmark for quality and performance.

This comprehensive guide explores the full sheet metal fabrication process, highlights Bangalore’s booming manufacturing ecosystem, and examines how Zeometrix is driving precision engineering and industrial advancement in the region.

The Sheet Metal Fabrication Process: From Concept to Finished Component

Sheet metal fabrication begins long before any metal is cut or shaped. It starts with meticulous planning and design, followed by a series of carefully coordinated processes that transform raw material into functional, high-performance components.

1. Design and Engineering

Every fabrication project begins with CAD (Computer-Aided Design). Engineers create detailed blueprints specifying:

-

Material type (steel, aluminum, stainless steel, copper, and more)

-

Thickness (gauge) of the sheet

-

Tolerances and geometric dimensions

-

Manufacturing sequence

-

Finishing requirements

These digital models are used to simulate the fabrication steps, detect design issues early, and optimize material usage. Zeometrix’s engineering team collaborates closely with clients during this stage to refine designs for manufacturability, ensuring cost efficiency and faster production.

2. Cutting

Cutting is often the first physical step in fabrication. Various tools are used based on material, thickness, and complexity:

-

Laser Cutting: Ideal for intricate designs and precise contours. CNC laser machines achieve extremely fine tolerances with minimal waste.

-

Shearing: A cost-effective method for straight-line cuts.

-

Waterjet Cutting: Useful for heat-sensitive materials, as the cold-cut process avoids thermal distortion.

-

Plasma Cutting: Best suited for thicker metals and high-speed operations.

Zeometrix uses advanced CNC laser cutting to achieve clean, accurate edges—even for complex parts used in EVs, medical devices, and aerospace systems.

3. Bending and Forming

Once cut, sheets are shaped using press brakes or rolling machines. These tools create bends, curves, and angular forms that turn flat sheets into functional structures. With CNC-controlled press brakes, Zeometrix ensures repeatability and precision—even for large-volume or multi-bend components.

4. Punching

Punching involves creating holes, slots, louvers, and complex patterns using CNC turret presses. It is essential for components like electronic enclosures, battery housings, cabinets, and chassis. Automated punching machines enable rapid production while maintaining design accuracy.

5. Welding and Assembly

Welding fuses parts into strong, durable assemblies. Depending on the project, techniques may include:

-

MIG Welding

-

TIG Welding

-

Spot Welding

-

Robotic Welding for unmatched consistency and speed

Zeometrix leads the way with Yasaka robotic welders, ensuring precise welds with minimal human error. These robotic systems improve structural integrity and drastically reduce production time, especially for large batch orders.

6. Finishing

Finishing enhances both durability and aesthetics. Options include:

-

Powder coating

-

Polishing

-

Painting

-

Silk screening

-

Anodizing (for aluminum)

Zeometrix’s powder coating and finishing services help achieve corrosion resistance, improved appearance, and long-lasting performance. The company integrates all steps under one roof at its Bannerghatta Road and Arekere Gate facilities for seamless production from prototype to full-scale manufacturing.

Bangalore’s Manufacturing Boom: Why the City Leads in Fabrication Innovation

Known globally as India’s Silicon Valley, Bangalore is rapidly evolving into a manufacturing powerhouse as well. The city’s strategic ecosystem—featuring startups, global suppliers, R&D centers, and tech-driven industries—has fueled tremendous growth in sheet metal fabrication.

A Thriving Industrial Hub

Bangalore hosts over 1,100 global suppliers, multiple industrial clusters, and technology companies adopting Industry 4.0 automation, including AI-driven inspection systems, robotic assembly lines, and digital manufacturing platforms. These advancements drive precision, efficiency, and faster product cycles.

Highly Skilled Workforce

The city benefits from a strong talent pool:

-

CAD/CAM engineers

-

CNC machine operators

-

Welding specialists

-

Quality inspection experts

Engineering colleges and technical institutes produce professionals trained in the latest tools, which accelerates innovation and ensures global-standard manufacturing.

Cost-Effective Production

Bangalore’s automated manufacturing processes help companies achieve a 20–30% reduction in production costs. These savings come from:

-

Reduced material waste

-

High-speed robotic equipment

-

Optimized workflows

-

Local sourcing

Fabrication companies like Zeometrix leverage these advantages to deliver competitive pricing without compromising quality.

Cutting-Edge Infrastructure

Modern manufacturing facilities in Bangalore house advanced equipment such as Yawei shearing machines, CNC press brakes, and robotic welders capable of handling high-complexity projects.

This industrial ecosystem provides the perfect foundation for high-precision sheet metal fabrication across sectors like EVs, aerospace, medical devices, and consumer electronics.

Zeometrix: Pioneering Precision Engineering in Bangalore

Among the many fabrication companies in Bangalore, Zeometrix stands out for its commitment to precision, automation, and customer-centric innovation. Known for providing powder coating and finishing services for sheet metal parts in Bangalore, Zeometrix complements its state-of-the-art CNC laser cutting, automated bending, and robotic welding capabilities to consistently deliver parts with tolerances under 0.1 mm, making it one of the most accurate fabrication providers in the region.

End-to-End Manufacturing Services

Zeometrix offers complete support throughout the product lifecycle:

-

Design consultation

-

Rapid prototyping

-

Material selection guidance

-

CNC cutting and forming

-

Robotic welding

-

Assembly and finishing

Their digital manufacturing platform links designers and production engineers directly, cutting lead times by up to 50%. This ensures faster market entry—critical for startups and tech-driven enterprises.

Sustainability at the Core

Zeometrix incorporates environmentally responsible practices:

-

Waste minimization

-

Energy-efficient machinery

-

Eco-friendly processes like waterjet cutting

These initiatives make the company a trusted partner for organizations prioritizing green manufacturing.

Serving Diverse Industries

Zeometrix delivers reliable sheet metal solutions for:

-

Medical device components

-

Aerospace brackets and enclosures

-

EV battery housings and body structures

-

Telecom and server cabinets

-

Industrial machinery parts

Their expertise enables both large production runs for automotive giants and small, custom prototypes for R&D-focused companies.

Key Benefits of Modern Sheet Metal Fabrication

Modern fabrication techniques provide advantages that are essential for today’s manufacturing landscape:

1. Precision and Customization

Laser cutting and CNC tools allow companies to achieve shapes, patterns, and tolerances impossible with traditional tools. This level of accuracy is critical for EV safety components, medical equipment housings, and aerospace assemblies.

2. Cost Efficiency

Automation reduces human error, speeds up production, and minimizes scrap material. Companies can scale to high-volume output while maintaining consistent quality.

3. Durability and Versatility

Fabricated sheet metal parts resist corrosion, withstand rough environments, and support everything from electronics to construction machinery.

4. Speed to Market

With rapid prototyping and streamlined workflows, new products can be introduced in days instead of weeks—an advantage that keeps Bangalore’s industries competitive.

5. Sustainability

Technologies like waterjet cutting eliminate heat distortion and reduce waste, aligning with global environmental standards.

These benefits make sheet metal fabrication one of the most reliable and adaptable manufacturing processes across sectors.

Industry Applications and Innovations

Sheet metal fabrication plays a crucial role across industries:

-

Aerospace: Lightweight aluminum and titanium parts improve fuel efficiency and safety.

-

Electric Vehicles: Precision battery enclosures, brackets, and structural parts enhance vehicle performance.

-

Medical Devices: Stainless steel assemblies ensure sterility and precision.

-

Electronics: Compact, EMI-shielded cabinets and enclosures support modern computing needs.

Future Innovations

The future of sheet metal fabrication in Bangalore includes:

-

AI-driven inspection and quality checks

-

Hybrid materials combining metals with composites

-

Integration of additive manufacturing (3D printing)

-

Smart factories using IoT sensors for real-time monitoring

Zeometrix is already adopting many of these technologies, ensuring its clients stay ahead of industry trends.

Conclusion

Sheet metal fabrication is redefining Bangalore’s manufacturing capabilities by merging precision technology, skilled craftsmanship, and cost-efficient solutions. As a leading provider of sheet metal fabrication for medical device components in Bangalore, Zeometrix stands at the forefront of this revolution, offering world-class CNC machining, robotic welding, and comprehensive finishing services—including powder coating and polishing—for long-lasting performance.

Whether you’re a startup developing prototypes or a large enterprise requiring high-volume production, partnering with Zeometrix ensures reliability, speed, and engineering excellence.

Transform your operations today—contact Zeometrix at www.zeometrix.com or +91 8095141417.

FAQs

1. What is sheet metal fabrication?

Sheet metal fabrication involves cutting, bending, forming, welding, and finishing flat metal sheets into custom components using CNC machinery, laser cutters, and robotic welders.

2. Why choose Zeometrix in Bangalore?

Zeometrix offers unmatched precision, fast turnaround, and end-to-end services using advanced equipment—ideal for industries like aerospace, EVs, telecom, and medical devices.

3. What materials does Zeometrix fabricate?

Common materials include aluminum, mild steel, stainless steel, galvanized steel, and specialized alloys.

4. How long does fabrication take at Zeometrix?

Prototypes are typically delivered in a few days, while production runs benefit from automation for up to 50% faster delivery.

5. What finishing options are available?

Finishing services include powder coating, silk screening, painting, polishing, and anodizing.