Bangalore's Industrial Backbone: Exploring the Indispensable Role of Zeometrix Sheet Metal Services

Driving this industrial strength is the growing precision sheet metal works and welding Bangalore sector, which delivers high-quality fabrication, tailored engineering solutions, and reliable production support to companies across aerospace, electronics, automotive, and medical manufacturing, ensuring advanced technical development throughout the region.

Among the leading lights in this critical sector is Zeometrix. We don't just cut and bend metal; we transform raw materials into complex, high-tolerance realities that fuel the next generation of industrial and consumer products. This comprehensive guide will take you through the indispensable role of sheet metal works in Bangalore, highlight the advanced technology that defines our craft, and explain why Zeometrix stands out as your ultimate precision manufacturing partner.

Bangalore: The Epicenter for High-Precision Manufacturing

The demand for high-quality, reliable sheet metal fabrication in Bangalore is unparalleled, driven by its unique industrial ecosystem. Unlike other manufacturing hubs, Bangalore's fabricators must adhere to extremely tight tolerances and stringent quality controls dictated by its core sectors. This necessitates a culture of zero-defect manufacturing and continuous technological upgrade.

-

Aerospace & Defence: Requiring specialized materials (e.g., lightweight aluminium and specialized alloys) and absolute traceability of every component, often governed by military-grade specifications.

-

Electronics & Telecom: Needing aesthetic, durable, and thermally efficient enclosures for servers, control panels, and outdoor kiosks, where heat management is as crucial as physical protection.

-

Automotive & Electric Vehicles (EV): Demanding robust, safety-critical battery enclosures, frames, and custom press parts that must withstand vibration and crash forces.

-

Medical Devices: Calling for clean, sterile, and non-corrosive components made primarily from Stainless Steel, requiring impeccable surface finishes and hygiene standards.

This diverse and demanding client base has forced the industry to evolve, making the adoption of CNC (Computer Numerical Control) technology not a luxury, but a necessity for survival.

The Zeometrix Advantage: Technology, Precision, and End-to-End Control

At Zeometrix, our commitment to precision is absolute, and it begins with our state-of-the-art facility and integrated manufacturing process. We have invested heavily in the cutting-edge machinery and software necessary to deliver parts with tolerances often measured in microns.

1. Cutting-Edge Fabrication Technologies: The Fiber Laser Difference

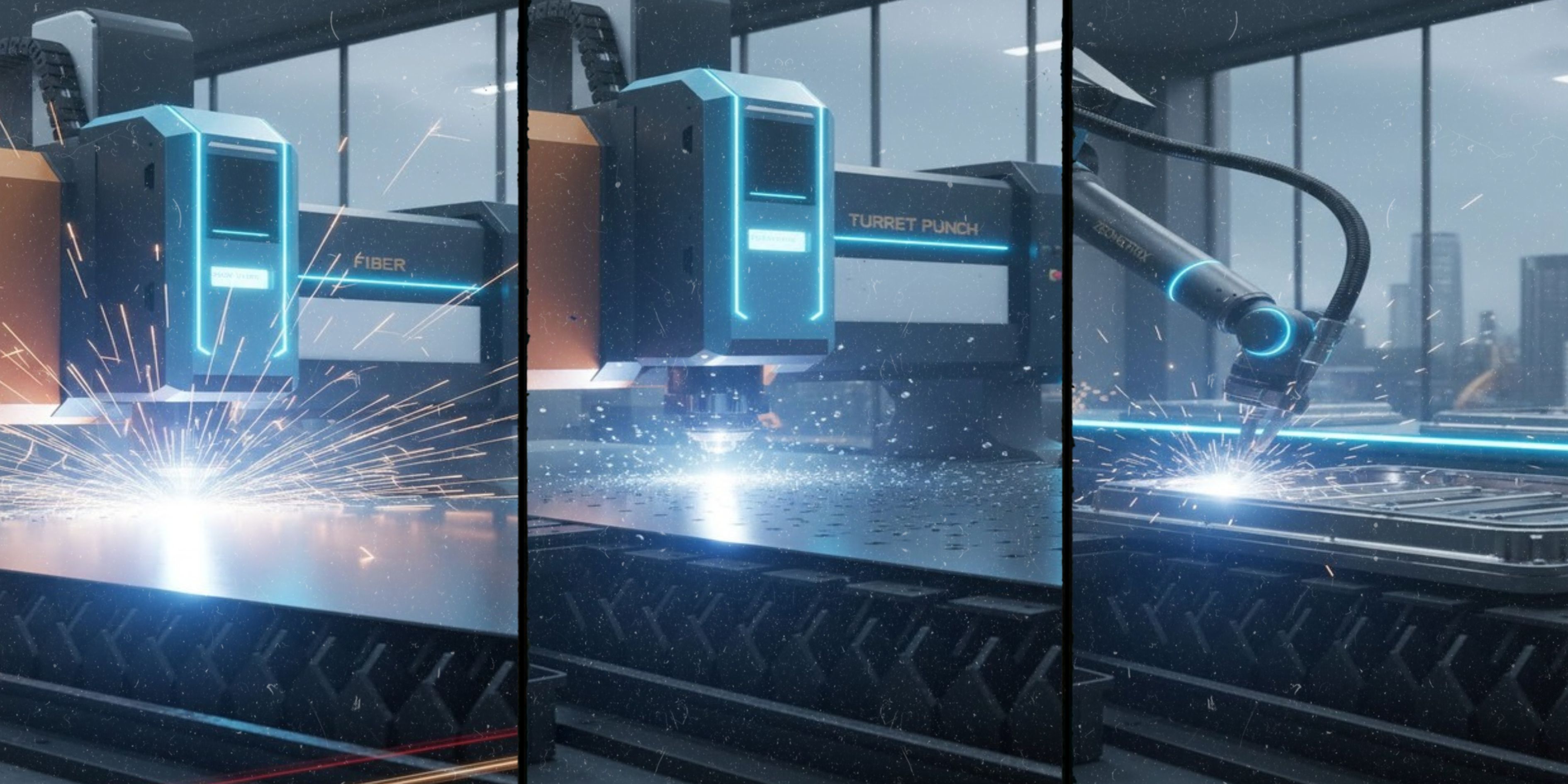

Our shop floor is equipped with world-class machines that define precision and efficiency:

-

CNC Fiber Laser Cutting: This technology represents a massive leap forward from older CO2 laser systems. Fiber lasers deliver a highly concentrated beam via an optical fiber, resulting in:

-

Higher Speeds: Especially when cutting thin to medium-thickness sheets of Mild Steel and Stainless Steel.

-

Superior Material Versatility: Unlike CO2, the fiber laser wavelength is highly effective at cutting highly reflective non-ferrous metals like copper, brass, and aluminum without risking machine damage.

-

Exceptional Edge Quality: Minimizing the heat-affected zone (HAZ) and reducing the need for post-cut finishing, which is critical for precise assembly.

-

Nesting Optimization: Advanced software integrates directly with our laser cutters to calculate the most efficient layout of parts on a single sheet, a technique called nesting. This significantly reduces material waste and lowers the unit cost for the client.

-

-

CNC Turret Punching: Ideal for high-volume jobs requiring repetitive hole patterns, louvers, or standard cutouts, our turret punch presses deliver incredible speed and consistency. It’s a highly cost-effective method for parts with many standard geometric features where laser cutting time might be prohibitive.

-

CNC Press Brake Bending: Our computer-controlled press brakes use digital precision to apply immense force, forming sheets into complex 3D shapes. Key to this process is compensating for "spring-back," the tendency of the metal to partially return to its original shape after bending. Our machines use angle-sensing technology to measure the bend in real-time and automatically over-bend slightly to achieve the precise target angle. This guarantees repeatable accuracy and dimensional consistency across thousands of parts, often leveraging tooling that defines the K-factor and bend deduction for material-specific calculations.

-

Advanced Welding & Assembly: We utilize specialized welding techniques, including MIG (for speed and structural integrity), TIG (for fine, aesthetic, and leak-proof welds), and Spot Welding (for fast, localized joins). Crucially, our engineers specialize in building complex sub-assemblies and final enclosures, providing our clients with a "plug-and-play" component rather than just loose parts.

2. Design for Manufacturability (DFM) Partnership

One of our greatest differentiators is our proactive approach to the design phase. Long before the first sheet is cut, the Zeometrix engineering team collaborates with clients to implement Design for Manufacturability (DFM) principles. This consultative process is crucial for minimizing hidden costs and production pitfalls—especially for projects involving industrial sheet metal works for factories Bangalore.

-

Optimizing Bend Geometry: We advise on standardizing bend radii to reduce the number of required tooling changes, and ensure the distance between a bend and an adjacent hole or cutout is sufficient to prevent tear-out during forming.

-

Material Utilization: Suggesting minor geometric changes that reduce material scrap, minimizing unused areas of the sheet, which directly impacts project costs.

-

Hardware and Insertion: Providing expertise on the correct use of self-clinching fasteners (studs, nuts, standoffs) and ensuring the sheet metal thickness is appropriate for secure insertion, enhancing structural integrity.

3. Integrated Software and Quality Control Systems

The efficiency of our physical production is mirrored by the sophistication of our digital infrastructure.

-

ERP/MRP Systems: Zeometrix utilizes integrated Enterprise Resource Planning (ERP) and Manufacturing Resource Planning (MRP) systems to manage the entire lifecycle of a job, from quoting and material procurement to production scheduling and final shipping. This system provides complete material traceability—every sheet can be traced back to its mill certificate—and ensures reliable lead time predictability.

-

Quality Assurance (QA) with CMM: Zeometrix maintains rigorous ISO 9001:2015 certified quality standards. Every batch undergoes thorough dimensional inspection. For complex parts and critical features, we use a Coordinate Measuring Machine (CMM). This device uses a probe to take highly accurate measurements in 3D space, verifying compliance with the tightest tolerances, especially for complex non-prismatic shapes. This commitment to Zero-Defect Manufacturing is the promise we deliver on every project.

Serving the New Economy: Zeometrix's Key Industry Focus

Focus 1: Electric Vehicle (EV) and Energy Storage - Safety and Thermal Management

The EV revolution is placing unprecedented demands on sheet metal fabrication, primarily concerning safety and thermal dynamics. We specialize in fabricating high-strength, shock-resistant battery enclosures and trays. This requires:

-

High-Integrity Welding: Ensuring the battery enclosure is sealed against moisture and dust (often requiring an IP rating) and can withstand significant vibration and impact forces without compromising the sensitive battery cells inside.

-

Thermal Management Features: Incorporating specialized louvers, vents, and internal mounting brackets designed to channel cooling air or fluids, maintaining the optimal operating temperature for the lithium-ion batteries, which is crucial for range and lifespan. The choice of aluminum alloys is often preferred here due to their excellent heat dissipation properties.

Focus 2: Electronics and Data Centers - Aesthetic and Functional Enclosures

We are experts in creating enclosures that are both aesthetically pleasing for consumer use and highly functional for industrial applications. Our expertise extends to manufacturing sophisticated server racks and network cabinets that adhere to standardized rack units (U). These enclosures are meticulously designed to manage cable routing and support high static loads, while their perforated sheet metal doors are engineered for maximum airflow and cooling efficiency, a necessity in modern high-density data centers.

Focus 3: Aerospace Sub-Assemblies - The Pursuit of Lighter, Stronger Components

In the aerospace sector, the primary drivers are lightweighting and strength. Zeometrix works with certified aerospace-grade materials, focusing on precise cutting and forming of complex sub-assemblies and brackets. The complete documentation and traceability provided by our ERP system are non-negotiable requirements for this highly regulated industry.

Conclusion: Your Precision Partner in Bangalore

Choosing a sheet metal partner in a competitive market like Bangalore requires looking beyond just the price tag. You need a partner who offers a combination of technical superiority, process integration, and unwavering reliability.

-

Unwavering Precision: The assurance that every part meets the strictest dimensional standards guaranteed by our CNC and CMM technologies.

-

Scalability: The capacity to handle everything from a single prototype batch to high-volume OEM production runs without compromising consistency.

-

Integrated Service: A single source for design, cutting, bending, welding, and finishing, simplifying your supply chain and dramatically reducing logistical headaches and overall lead times.

At Zeometrix, we are dedicated to fostering long-term partnerships built on reliability, transparent communication, and a shared commitment to quality. As one of the reliable sheet metal works contractors in Bangalore, our state-of-the-art facility is ready to turn your complex designs into perfectly engineered metal components.

Ready to bring your next product to market with uncompromised quality and speed? Contact Zeometrix today.

Frequently Asked Questions (FAQs)

1. What is the typical tolerance achieved in precision sheet metal fabrication?

The achievable tolerance depends on the material, thickness, and the specific fabrication process. At Zeometrix, using modern CNC fiber laser cutting and press brakes, we routinely achieve tolerances as low as $\pm 0.1 \text{ mm}$ for critical features such as bend lines and mounting holes, which is necessary for integration into larger assemblies. For general features, tolerances typically range from $\pm 0.2 \text{ mm}$ to $\pm 0.5 \text{ mm}$. Our CMM inspection process ensures we meet even the most demanding specifications.

2. Which materials does Zeometrix commonly use, and how do I choose the right one?

We work with a wide range of materials, including: Mild Steel (MS) / Carbon Steel, Stainless Steel (SS 304 & 316), Aluminum (5052 & 6061), and Galvanized Iron (GI). The choice is primarily driven by your product's functional requirements:

-

SS: Best for corrosion resistance and hygiene.

-

Aluminum: Ideal for lightweighting and thermal management (EV, electronics).

-

MS: Most cost-effective choice where high strength and structural integrity are key.

We provide DFM consulting to balance these technical needs with your budget.

3. Does Zeometrix handle both prototyping and large-scale production?

Yes. Zeometrix is equipped for both Rapid Prototyping and High-Volume OEM production. For prototypes, we utilize flexible CNC methods with minimal setup costs. For large-scale orders, we leverage the full efficiency of automated bending and stamping, where the initial tooling cost is justified and spread over thousands of units, ensuring highly competitive pricing and quality consistency.

4. What surface finishing options do you offer for fabricated parts?

To ensure durability, corrosion resistance, and a professional aesthetic, we offer a full spectrum of finishing services:

-

Powder Coating: This is our most popular finish, providing a tough, durable, and chemical-resistant layer in virtually any color. The process involves electrostatically applying dry powder and curing it under heat.

-

Plating: Such as Zinc, Nickel, or Chrome plating for enhanced surface hardness and superior sacrificial corrosion protection.

-

Anodizing: Specifically for Aluminum parts, creating a thicker, natural oxide layer that resists corrosion and wear.

5. What are the key elements of cost in sheet metal fabrication?

The total cost is a function of four primary factors:

-

Material Cost: The type and thickness of the sheet metal (SS and Aluminum are pricier than MS).

-

Processing Time: The complexity of cuts, the number of bends, and the time spent on welding/assembly.

-

Setup Costs (Tooling): Initial investment, especially for high-volume stamping dies or specialized press brake tooling.

-

Finishing: The chosen coating (e.g., standard paint vs. specialized anti-microbial powder coat).

We aim to minimize all these costs through DFM consultation and efficient nesting software.