Precision Perfected: Why Zeometrix is the Leader in Sheet Metal Fabrication in Bangalore

Introduction

In today’s rapidly evolving manufacturing landscape, precision has become more than just a desirable quality—it is the foundation upon which modern engineering and product innovation are built. From electric vehicles and medical equipment to aerospace systems and advanced electronics, every industry depends on components that are accurately engineered and flawlessly fabricated. As Bangalore has grown into India’s leading hub for technology, engineering, and manufacturing, the demand for highly reliable sheet metal fabrication services has increased dramatically. Meeting this demand with unmatched quality and professionalism is Zeometrix, a company widely recognized as a leader in Sheet Metal Fabrication in Bangalore.

Zeometrix has successfully established itself as the preferred fabrication partner for businesses that value precision, durability, and consistent performance. With advanced machinery, a skilled workforce, and an uncompromising commitment to quality, the company has redefined what excellence in sheet metal fabrication looks like. This detailed blog explores the many reasons why Zeometrix stands out as the top choice for fabrication services in Bangalore.

A Legacy of Precision Engineering

Precision is at the heart of Zeometrix’s operations. Sheet metal fabrication requires exact measurements, clean cuts, and flawless assembly. Even the smallest error can impact the performance and safety of an entire system. Understanding this, Zeometrix follows a meticulous and systematic fabrication process where every detail is checked, verified, and inspected.

Each project begins with thorough design analysis, where engineers ensure the concept is manufacturable and optimized for both cost and performance. The production process is monitored every step of the way, and advanced tools ensure components meet the tight tolerance levels required by modern industries. This focus on precision has helped Zeometrix build trust with companies that cannot afford even a 1% deviation in quality.

World-Class Fabrication Infrastructure

A major reason behind Zeometrix’s leadership status is its investment in state-of-the-art infrastructure. Unlike many workshops that rely on outdated equipment, Zeometrix operates with modern, high-capacity machines that guarantee speed, accuracy, and repeatability.

1. CNC Laser Cutting Machines

.jpg)

These machines allow for ultra-precise cutting with minimal thermal distortion. They handle complex shapes and delicate patterns effortlessly, enabling engineers to transform even the most intricate designs into real-world components.

2. CNC Turret Punching Systems

Used for high-volume repetitive fabrication, turret punching ensures fast production with consistent hole sizes, slots, and patterns.

3. Multi-Axis CNC Press Brakes

Accurate bending is one of the most challenging aspects of fabrication. Zeometrix’s multi-axis press brakes deliver perfect angles and clean bends for a wide range of materials and thicknesses.

4. Advanced Welding Facilities

Whether it’s TIG, MIG, or spot welding, Zeometrix’s certified welders ensure every joint is strong, clean, and structurally sound.

5. High-End Surface Finishing Units

Finishing plays a major role in durability and aesthetics. Powder coating, anodizing, galvanizing, and polishing services ensure components remain corrosion-resistant and visually appealing.

Having all these capabilities in one place enables Zeometrix to maintain quality control throughout the production process, reduce lead times, and eliminate dependency on third-party services.

A Skilled Team Driving Excellence

Beyond machinery, Zeometrix’s true strength lies in its people. Their team includes experienced engineers, designers, machine operators, and quality control experts who work together to deliver exceptional results.

Engineering Expertise

Engineers collaborate with customers to refine designs, identify flaws, and recommend improvements that enhance functionality without increasing costs.

Precision Technicians

Trained professionals handle laser cutting, bending, welding, and assembly, ensuring every stage of production meets the highest standards.

Quality Assurance Specialists

The QA team inspects each part with advanced tools and checklists. From dimensional accuracy to finishing consistency, no detail is overlooked.

This combination of talent and technology allows Zeometrix to consistently exceed client expectations.

Tailored Solutions for Diverse Industries

What truly distinguishes Zeometrix as a leading sheet metal fabrication manufacturer is its ability to deliver customized sheet metal solutions for a variety of industries. No two sectors have the same requirements, and Zeometrix understands this perfectly.

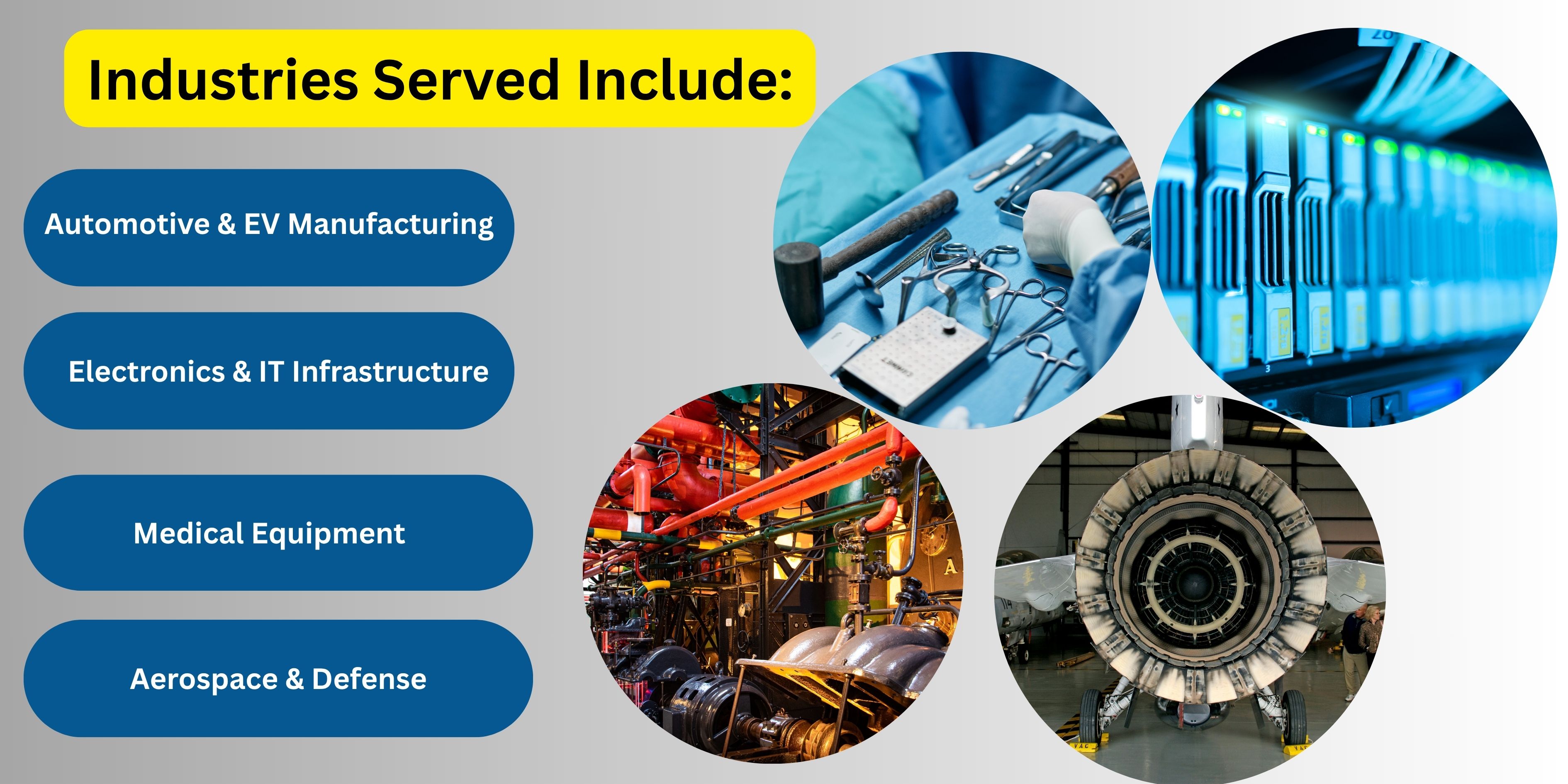

Industries Served Include:

- Automotive & EV Manufacturing

Components such as battery trays, motor housings, custom brackets, and chassis parts.

- Aerospace & Defense

Lightweight yet durable structures designed for safety and performance.

- Electronics & IT Infrastructure

Server racks, enclosures, cabinets, mounting structures, and EMI-shielded designs.

- Medical Equipment

Hygienic, precision-engineered parts essential for accurate diagnostic and treatment devices.

- Renewable Energy & Solar Systems

Metal frameworks, structures, and assemblies built for outdoor durability.

- Construction & Architectural Fabrication

Railings, decorative panels, metal fixtures, and structural components.

This industry-wide experience showcases Zeometrix’s versatility and ability to meet highly specific operational and regulatory requirements.

Commitment to Quality at Every Stage

Quality is ingrained in Zeometrix’s work culture. Every component undergoes a multi-step inspection to ensure it meets the highest standards. Their commitment to quality is demonstrated through:

- Strict raw material verification

- Tolerance-based dimensional checks

- Welding strength and accuracy tests

- Surface finish inspection

- Fitment trials and assembly tests

- Final quality audits before dispatch

This end-to-end focus ensures customers receive components that are reliable, safe, and ready for real-world performance.

Fast Turnaround Without Compromising Accuracy

In industries where deadlines are crucial, Zeometrix stands out for its ability to deliver projects quickly without sacrificing quality. Automated machinery, well-structured workflows, and trained technicians ensure faster production cycles. Whether it’s a single prototype or mass manufacturing, clients can expect prompt service and consistent communication throughout the process.

Competitive Pricing & Transparent Customer Communication

Despite offering world-class services, Zeometrix maintains competitive pricing. Their quotations are transparent, detailed, and free from hidden charges. Customers appreciate the honesty, clarity, and professionalism shown during the entire project.

This transparency builds long-term relationships and encourages repeat business—something Zeometrix has proudly achieved over the years.

End-to-End Design-to-Delivery Support

Zeometrix offers complete assistance from concept to completion. Clients who only have sketches or basic ideas can receive full engineering support, including:

- 3D modeling

- Design optimization

- Material consultation

- Prototype development

- Mass manufacturing

This end-to-end capability ensures a smoother journey from idea to finished product.

Conclusion

Zeometrix has earned its position as the leader in Sheet Metal Fabrication in Bangalore by consistently delivering precision, innovation, and reliability. With its advanced technology, dedicated team, strong quality standards, and commitment to customer satisfaction, Zeometrix continues to empower industries with top-tier fabricated components. Whether you are a startup looking for prototypes or an established manufacturer requiring high-volume production, Zeometrix stands out as the ideal fabrication partner—delivering excellence every step of the way.

Frequently Asked Questions (FAQ)

1. Which industries does Zeometrix serve?

Zeometrix caters to automotive, aerospace, electronics, medical, renewable energy, telecom, and construction industries.

2. What materials does Zeometrix work with?

They fabricate components using stainless steel, aluminum, mild steel, galvanized sheets, copper, and various alloys.

3. Does Zeometrix take prototype orders?

Yes. Zeometrix handles everything from single prototypes to large-scale manufacturing with equal precision.

4. What services are offered?

Laser cutting, turret punching, CNC bending, welding, assembly, powder coating, anodizing, and complete finishing services.

5. What is the typical delivery time?

Lead time depends on project complexity, but Zeometrix is known for fast delivery without compromising accuracy.