Engineering Excellence in Metal: How Zeometrix Leads Sheet Metal Production in Bangalore

In the heart of India's technological capital, the manufacturing sector is undergoing a massive transformation. As industries move toward miniaturization, electric mobility, and sustainable infrastructure, the demand for high-precision metal components has skyrocketed. Searching for sheet metal fabrication companies in Bangalore yields hundreds of results, but for businesses that require uncompromising quality and engineering depth, the choice narrows significantly.

Zeometrix has established itself as a premier partner in this competitive landscape. This article explores the intricacies of sheet metal fabrication, the unique advantages of Bangalore’s industrial ecosystem, and how Zeometrix leverages technology to deliver world-class solutions.

1. The Strategic Importance of Bangalore in Global Manufacturing

Bangalore is no longer just a software hub; it is a critical node in the global supply chain for hardware and heavy engineering. The city’s evolution from "Garden City" to "Manufacturing Powerhouse" is fueled by several factors that benefit clients looking for sheet metal services.

The Industrial Corridor Advantage

Bangalore is surrounded by massive industrial estates such as Peenya (one of the largest in Southeast Asia), Dabaspete, Jigani, and Hoskote. These areas house an interconnected web of raw material suppliers, heat treatment plants, and surface coating specialists. When you work with a company like Zeometrix, you aren't just hiring a workshop; you are tapping into a sophisticated logistical network that ensures projects move from raw steel to finished product without regional bottlenecks.

A Culture of Engineering Excellence

With institutions like the Indian Institute of Science (IISc) and various R&D centers nearby, the workforce in Bangalore possesses a high degree of technical literacy. At Zeometrix, this translates to a floor of operators who understand the "why" behind a design, not just the "how." This intellectual depth is vital when dealing with complex aerospace or medical-grade specifications where a minor deviation can lead to catastrophic failure.

2. The Anatomy of Modern Sheet Metal Fabrication

To appreciate what sets the top sheet metal fabrication companies in Bangalore apart, one must understand the journey a flat sheet of metal takes to become a finished product. At Zeometrix, this journey is governed by Industry 4.0 principles.

A. Design for Manufacturing (DFM)

The fabrication process at Zeometrix begins long before the laser is fired. Our engineers engage in Design for Manufacturing (DFM) analysis. We review client CAD files to identify potential issues, such as holes placed too close to a bend line or overly complex geometries that could be simplified to reduce costs without sacrificing strength. By optimizing the design at the outset, we ensure a higher success rate and lower material waste.

B. Precision Cutting: The Power of Fiber Lasers

Traditional cutting methods often leave burrs or cause heat-affected zones that weaken the metal. Zeometrix utilizes state-of-the-art Fiber Laser Cutting technology. Unlike older CO2 lasers, fiber lasers are faster, more precise, and capable of cutting reflective materials like brass and copper.

-

Tolerances: We achieve tolerances as tight as $\pm 0.1mm$.

-

Edge Quality: The cuts are so clean that secondary grinding is often unnecessary, saving time in the production cycle.

C. CNC Bending: Accuracy in Every Angle

Bending is where the "personality" of the metal comes into play. Different alloys have different "springback" rates. Zeometrix uses multi-axis CNC Press Brakes that allow for complex, multi-stage bends in a single setup. This ensures that every enclosure, chassis, or bracket is perfectly square and ready for assembly.

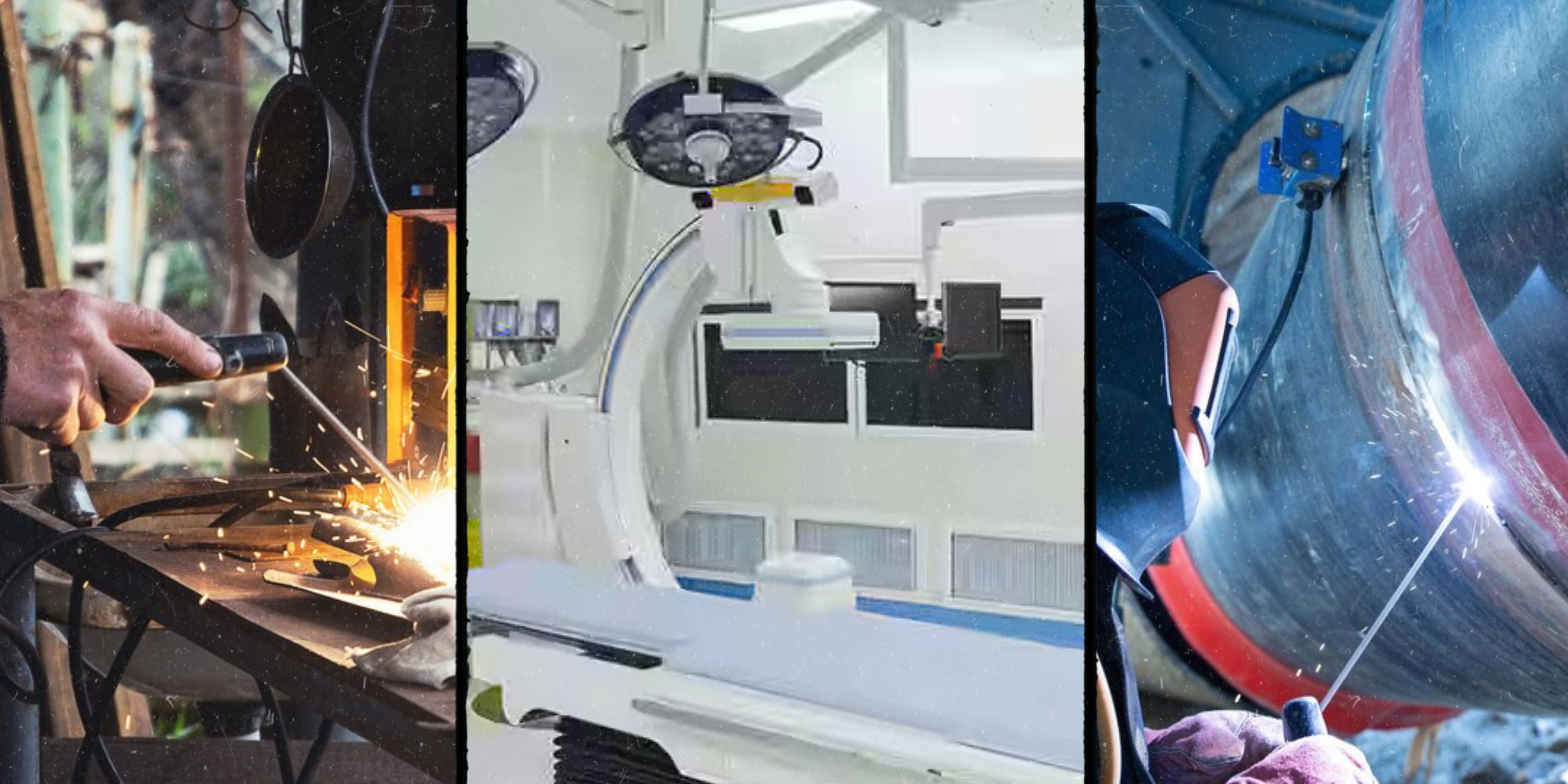

D. Joining and Welding Excellence

A product is only as strong as its weakest joint. Zeometrix offers a variety of welding services:

-

TIG Welding: For high-aesthetic, high-strength joins in stainless steel and aluminium.

-

MIG Welding: For structural steel components where speed and deep penetration are required.

-

Spot Welding: Ideal for creating lightweight but sturdy electronic enclosures.

3. Specialized Material Expertise

A major differentiator for Zeometrix is our ability to handle a diverse palette of materials. Each requires a different approach:

1. Stainless Steel (SS 304, 316, 430)

In Bangalore’s pharmaceutical and food processing industries, SS is non-negotiable. We understand the passivation processes required to ensure these metals remain rust-proof even in sterilized environments. Our technicians are trained to avoid "carbon contamination," which can happen if stainless steel is handled with tools used for mild steel.

2. Aluminium (5000 and 6000 Series)

As the EV (Electric Vehicle) market grows in Bangalore, aluminium has become the material of choice for battery trays and cooling plates. We manage the delicate thermal properties of aluminium to prevent cracking during the bending process, using specialized tooling to avoid surface marking.

3. High-Strength Mild Steel and GI

For telecommunication towers and heavy machinery enclosures, we use high-tensile MS that provides the necessary structural integrity. Galvanized Iron (GI) is also frequently used for outdoor cabinets to provide an extra layer of zinc-based corrosion protection.

4. Serving the Pillars of Modern Industry

Zeometrix caters to a wide array of sectors, each with its own set of stringent requirements. This diversity has allowed us to become one of the most versatile sheet metal fabrication companies in Bangalore, with strong expertise in sheet metal production.

Aerospace and Defense

Bangalore is the headquarters of ISRO and HAL. Fabrication for this sector requires 100% traceability of materials and incredibly tight tolerances. Zeometrix provides the documentation and precision required for ground support equipment, cockpit internal frames, and satellite housing components.

The EV and Energy Revolution

With the rise of companies like Ather and Ola Electric, Bangalore is the epicenter of India's EV shift. We produce:

-

Battery Enclosures: IP67-rated boxes that protect lithium-ion cells from moisture and impact.

-

Charging Stations: Vandal-resistant, weather-proof kiosks for public charging infrastructure.

-

Solar Inverter Housings: Durable enclosures for renewable energy systems.

Healthcare and Laboratory Equipment

We manufacture enclosures for MRI machines, diagnostic tools, and hospital furniture. These products require a "Class A" finish—meaning no visible welds, smooth edges, and a perfect powder-coated surface that can withstand rigorous chemical cleaning.

5. The Zeometrix Quality Assurance Framework

In a market where many "fabricators" are merely small workshops, Zeometrix stands out through its systematic approach to quality. We don't just inspect the final product; we inspect the process.

First Article Inspection (FAI)

Before a mass-production run begins, we produce a single "First Article." This part is subjected to a rigorous dimensional audit against the CAD model. Only after the client approves this sample does the high-speed production line start moving.

In-Process Monitoring

Our CNC machines are equipped with sensors that monitor tool wear and alignment. By catching a drifting tolerance in real-time, we prevent the creation of scrap and ensure that the 1,000th part is identical to the first.

Surface Finishing and Aesthetics

A fabricated part is not complete until it is protected. Zeometrix offers:

-

Powder Coating: A wide range of textures and colors with high UV resistance.

-

Anodizing: Essential for aluminium parts in aerospace or high-end consumer electronics.

-

Silk Screening: Adding logos, instructions, or branding directly onto the metal surface.

6. Sustainable Manufacturing in 2026

As we move further into 2026, sustainability is no longer optional. Zeometrix is committed to "Green Fabrication" through several initiatives:

-

Waste Minimization: Advanced nesting algorithms reduce raw material waste by up to 20% compared to manual layouts.

-

Energy Efficiency: Our newer fiber lasers consume significantly less electricity than older CO2 models, reducing the carbon footprint of every part we produce.

-

Circular Economy: We partner with certified recyclers to ensure that every scrap of MS, SS, and Aluminium is melted down and reused in the global supply chain.

7. How to Choose the Right Fabrication Partner

When evaluating sheet metal fabrication companies in Bangalore, businesses should look beyond the price per kilogram. Total cost of ownership includes the cost of delays, the cost of defects, and the cost of poor communication.

Questions to ask your fabricator:

-

Do you provide a full material test certificate (MTC) for the steel used?

-

Can you handle secondary operations like tapping, countersinking, and assembly?

-

What is your internal "Rejection Rate," and how do you handle non-conformities?

-

Do you have an in-house design team to assist with DFM?

Zeometrix prides itself on providing transparent answers to all these questions, building a foundation of trust that lasts for decades.

Conclusion

The search for the best sheet metal fabrication companies in Bangalore ultimately leads to a choice between a vendor and a partner. A vendor simply follows a drawing; a partner like Zeometrix understands the application, anticipates challenges, and adds value through engineering expertise.

By combining the agility of a local Bangalore shop with the quality standards of a global leader, Zeometrix continues to define the future of metalwork in Karnataka. Whether you are building the next generation of space tech or a simple industrial bracket, our commitment to precision, speed, and sustainability remains the same.

Frequently Asked Questions (FAQ)

1. What are the typical lead times for a project at Zeometrix?

For standard prototyping, we can often deliver within 5 to 7 working days. For bulk production, lead times usually range from 2 to 4 weeks, depending on the complexity of the finishing and assembly requirements. We always provide a firm timeline at the quotation stage.

2. Can Zeometrix work with 3D CAD files directly?

Yes, we prefer working with 3D formats such as .STEP, .IGES, or .SLDPRT. This allows us to feed the data directly into our CNC programming software, eliminating the risk of human error during manual data entry.

3. Do you offer "Just-in-Time" (JIT) delivery for large-scale manufacturers?

Absolutely. We work with several MNCs in Bangalore where we maintain a buffer stock in our warehouse and deliver parts on a weekly or daily basis according to their production schedule, helping them reduce their own inventory costs.

4. What is the maximum size of a single sheet you can process?

Our standard laser cutting beds can handle sheets up to 3000mm x 1500mm. For larger structures, we utilize modular designs that are welded or bolted together to create larger assemblies.

5. Is Zeometrix ISO certified?

Yes, we adhere to ISO 9001:2015 quality management standards. Our facility is regularly audited to ensure that our processes, from procurement to final shipping, meet the highest international benchmarks for manufacturing excellence.