Modern Metal Fabrication in Bangalore: Services, Standards, and a Closer Look at Zeometrix

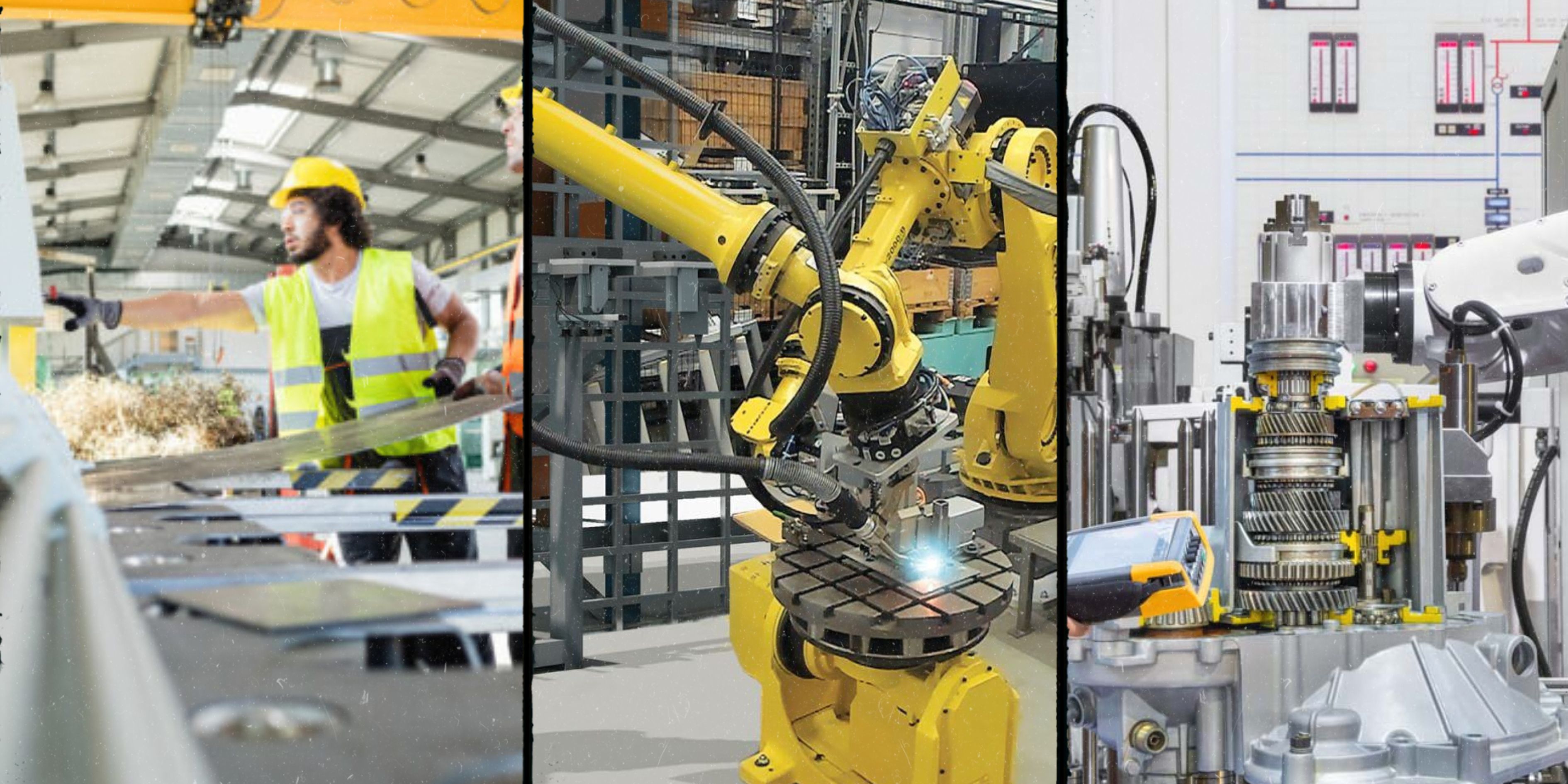

Finding the right manufacturing partner in a city as industrially diverse as Bangalore is no small feat. Known as the "Silicon Valley of India," the city has rapidly evolved into a powerhouse for high-tech manufacturing, aerospace, and heavy engineering. Whether you are looking for custom sheet metal work, complex industrial assemblies, or precision-engineered components, the landscape of fabrication companies in Bangalore offers a blend of traditional craftsmanship and futuristic technology.

Among the frontrunners in this space is Zeometrix, a company that has redefined the standards of precision and reliability in the region. In this comprehensive guide, we explore why Bangalore is the hub for fabrication, what to look for in a partner, and how Zeometrix stands out in a crowded market.

1. The Strategic Importance of Bangalore’s Fabrication Hub

Bangalore’s industrial geography is divided into massive clusters that specialize in different niches of manufacturing. To understand why the city is a magnet for fabrication, one must look at areas like Peenya, Bommasandra, and Jigani.

-

Peenya Industrial Area: Often cited as one of the largest industrial hubs in Asia, Peenya is the soul of Bangalore’s MSME (Micro, Small, and Medium Enterprises) sector. It is the go-to location for specialized job work and intricate component manufacturing.

-

Bommasandra & Jigani: These areas have evolved into specialized clusters for high-precision fabrication, serving the elevator, escalator, and electrical control panel industries.

-

Hoskote & Bidadi: Home to automotive giants, these regions drive the demand for heavy structural fabrication and robotic assembly lines.

By positioning themselves within this ecosystem, companies like Zeometrix gain access to a world-class supply chain, skilled metallurgical engineers, and a logistics network that connects them to the rest of the world.

2. Zeometrix: Redefining Fabrication Standards

When evaluating fabrication companies in Bangalore, Zeometrix stands out because of its commitment to "Quality-First" engineering. In a market where many vendors compete on price alone, Zeometrix competes on tolerance, durability, and technical transparency.

A Portfolio of Precision

Zeometrix has diversified its capabilities to handle the most demanding materials of 2026. Whether it is 30mm Mild Steel for heavy industrial bases or 0.5mm Stainless Steel for medical grade enclosures, their shop floor is equipped to handle it all.

Material Expertise

-

Mild Steel (MS): Used extensively in structural frames and heavy machinery.

-

Stainless Steel (SS 304/316): Critical for the food processing, pharmaceutical, and medical device sectors in Bangalore.

-

Aluminum Alloys: Essential for the aerospace and electric vehicle (EV) sectors due to their high strength-to-weight ratio.

-

Copper & Brass: Focused on electrical components and busbars for the thriving power sector.

3. Core Fabrication Services: A Deep Dive

To truly understand what the best fabrication companies in Bangalore offer, we need to look under the hood of their service offerings. Zeometrix provides a comprehensive suite that eliminates the need for multiple vendors.

I. CNC Laser Cutting

In 2026, CO2 lasers are largely a thing of the past. Zeometrix utilizes high-wattage Fiber Lasers. These machines offer:

-

Lower Heat-Affected Zones (HAZ): Ensuring the structural integrity of the metal is not compromised.

-

Complex Geometries: The ability to cut intricate patterns that would be impossible with traditional methods.

-

Speed: Fiber lasers are up to 3x faster on thin materials compared to older technologies.

II. Precision Bending (CNC Press Brake)

Bending is where many fabrication projects fail. A millimeter's difference can ruin an assembly. Zeometrix uses multi-axis CNC press brakes with automatic crowning compensation, ensuring that every bend is accurate to the degree, regardless of the length of the part.

III. Advanced Welding Techniques

Welding is an art form backed by science. At Zeometrix, the focus is on:

-

TIG (Tungsten Inert Gas) Welding: For clean, aesthetic welds on stainless steel and aluminum.

-

MIG (Metal Inert Gas) Welding: For high-strength joints in structural steel.

-

Robotic Welding: Used for high-volume production runs where consistency is non-negotiable.

IV. Surface Treatment and Finishing

A fabricated part is only as good as its finish. Zeometrix provides in-house or managed services for:

-

Powder Coating: For a durable, corrosion-resistant, and colorful finish.

-

Anodizing: Essential for aluminum parts in the electronics and aerospace industries.

-

Passivation: A chemical process for stainless steel to enhance its natural corrosion resistance.

4. Industry-Specific Applications in Bangalore

The versatility of sheet metal fabrication manufacturers is best demonstrated by the variety of industries they serve. Zeometrix has developed specialized workflows for the following sectors:

The Electric Vehicle (EV) Revolution

Bangalore is the heart of India’s EV movement. Fabrication here requires specialized knowledge of battery enclosures that are both lightweight and fire-resistant. Zeometrix works with EV startups to prototype and mass-produce aluminum battery housings and motor mounts.

Medical and Healthcare Devices

With the rise of "MedTech" in Bangalore, the need for surgical-grade fabrication has never been higher. Zeometrix produces hospital furniture, diagnostic equipment chassis, and laboratory enclosures that meet stringent hygiene and safety standards.

Aerospace and Defense

Proximity to HAL and ISRO means that fabrication companies in Bangalore must often adhere to aerospace standards. Zeometrix understands the documentation, traceability, and rigorous testing required for parts that go into the sky or beyond.

Data Center Infrastructure

As India digitizes, Bangalore has become a hub for data centers. This has created a massive demand for heavy-duty server racks, cooling manifolds, and structural support systems—all areas where Zeometrix excels.

5. Trends Transforming Bangalore’s Fabrication Industry in 2026

The industry is no longer stagnant. Several key trends are defining the future for players like Zeometrix:

-

Sustainable Fabrication: With the implementation of the EU’s Carbon Border Adjustment Mechanism (CBAM), exporters in Bangalore are switching to "Green Steel" and energy-efficient fiber lasers to reduce their carbon footprint.

-

AI in Production Planning: Zeometrix uses AI-driven nesting software to ensure that metal sheets are used with maximum efficiency, often reaching waste levels of less than 5%.

-

Digital Twins: For complex assemblies, Zeometrix creates a digital twin (a 3D virtual model) to simulate the assembly process before a single piece of metal is cut.

-

The Rise of Cobots: Collaborative robots (Cobots) now work alongside human welders at top facilities, handling the repetitive, heavy tasks while humans focus on the fine details.

6. Comparison: Organized vs. Unorganized Fabrication

When looking for fabrication companies in Bangalore, many clients are tempted by the low prices of small, unorganized workshops. However, the "Zeometrix Advantage" lies in the hidden costs of quality.

|

Feature |

Unorganized Workshop |

Zeometrix (Organized) |

|

Machinery |

Manual or used CNCs |

State-of-the-art Fiber Lasers |

|

Material Traceability |

Rare |

100% (Material Test Certificates) |

|

Quality Control |

Visual Check only |

Digital Metrology & Inspection |

|

Lead Times |

Unpredictable |

System-driven schedules |

|

Scalability |

Limited |

Prototype to Mass Production |

7. How to Onboard a Fabrication Partner

If you are ready to start your project with one of the premier fabrication companies in Bangalore, follow this 3-step process to ensure success with Zeometrix:

-

Prepare Your CAD Files: Most modern fabricators require .STEP, .DWG, or .DXF files. Ensure your tolerances are clearly marked.

-

Specify the Finish: Don't just ask for "painting." Specify the RAL code for powder coating or the thickness of the plating.

-

Request a Prototype: For large orders, always start with a "First Article Inspection" (FAI) to verify that the fabricator’s process matches your design intent.

Conclusion

The search for fabrication companies in Bangalore ends when you find a partner that treats your project with the same level of engineering rigor as you do. In 2026, Zeometrix continues to lead the charge, offering a perfect blend of technological prowess and local manufacturing heart. From the initial spark of an idea to the final powder-coated product, they represent the very best of Bangalore’s industrial spirit.

As the city continues to expand its global manufacturing footprint, choosing a partner like Zeometrix ensures that your business is not just keeping up with the competition—it’s staying ahead of it.

Frequently Asked Questions (FAQs)

1. Does Zeometrix offer "Design for Manufacturing" (DfM) services?

Yes. Zeometrix doesn't just take your drawings; their engineers review them to see if a different bend radius or hole placement could reduce material waste and lower your costs without compromising the part's function.

2. What is the maximum thickness Zeometrix can cut?

Using their high-power fiber lasers, Zeometrix can cut Mild Steel up to 30mm, Stainless Steel up to 20mm, and Aluminum up to 15mm with exceptional edge quality.

3. Can I get a quote for a single prototype?

While many large fabrication companies in Bangalore only take bulk orders, Zeometrix has a dedicated rapid prototyping wing designed to help startups and R&D departments get their first unit ready in record time.

4. How does Zeometrix ensure quality for export-bound parts?

Zeometrix follows international standards and provides full documentation, including Material Test Reports (MTRs) and Dimensional Inspection Reports, ensuring that parts shipped from Bangalore meet the compliance requirements of Europe and the USA.

5. Why are fiber lasers better than CO2 lasers for my project?

Fiber lasers are more efficient, faster on thin-to-medium materials, and can cut reflective metals like copper and brass which often damage older CO2 laser systems. This results in a lower cost-per-part for you.